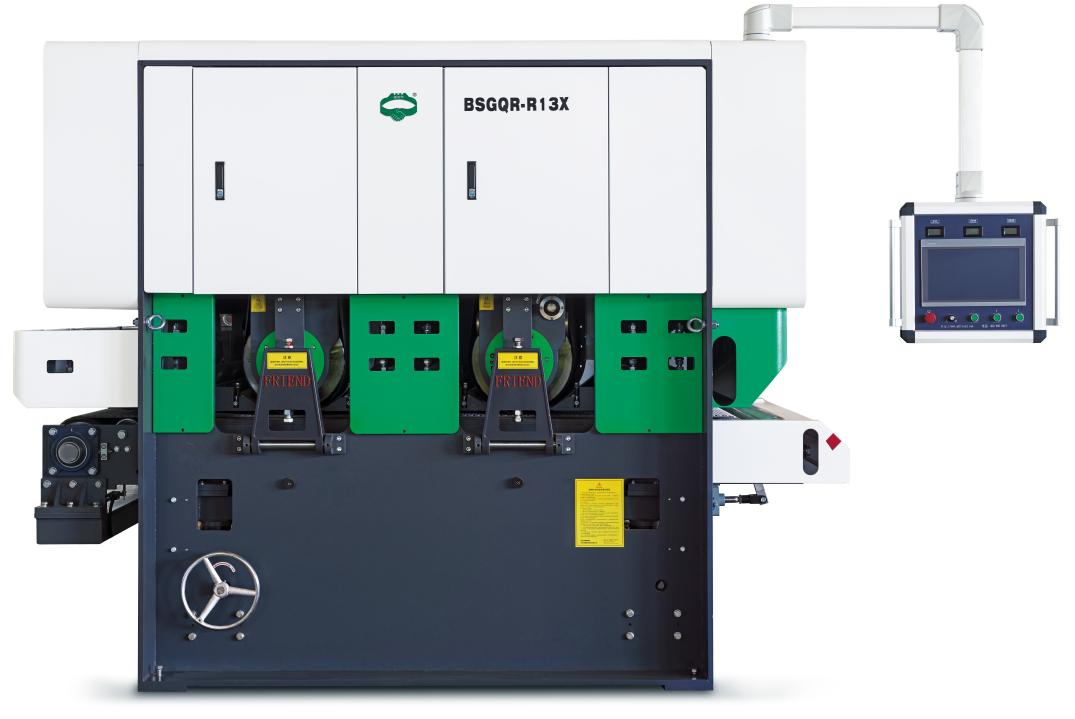

Working width 40-1300mm

Working thickness 3-80mm

Working length ≥750mm

Feeding speed 5-40m/min

Overall Dimension 3300×3000×2450mm

Weight 11000kg

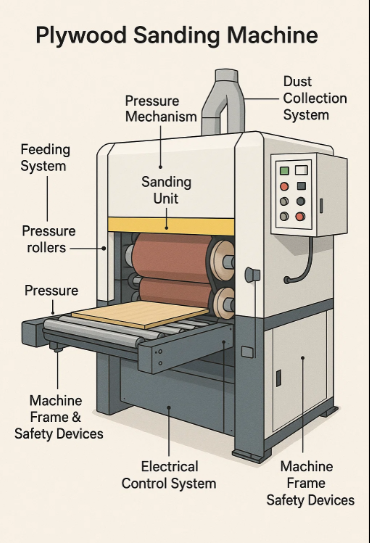

Why Do We Need a Sanding Machine?

After hot pressing, plywood is not always perfectly flat or even. The surface may have glue spots, dirt, or small marks. A sanding machine helps fix these problems. It smooths out the surface, makes the board flat and even, and removes any marks. This makes the plywood look better and easier for painting and lamination.

Technical parameters:

Sanding belt size 1340×2800mm

Sanding belt speed 24m/s

Diameter of contact roller 400mm steel roller

400mm rubber roller

Motor

Main motor power 75kW,55kW

Motor power of feeding 11kW

Motor power of lifting 0.75kW

Motor power of brushing 0.75kW

Voltage requirement 380V 50Hz 3Ph

Working air pressure 0.55MPa

Compressed air consumption 0.12m³/min

Speed of suction 25-30m/s

Volume of suction 23000m³/h

Feeding System

Includes feeding rollers, pressure rollers, and conveyor belts

Ensures smooth and consistent feeding of the plywood

Typically equipped with an inverter for variable speed control, enabling continuous and stable operation

Sanding Unit

The core working section, consisting of multiple sanding rollers

Divided into coarse sanding rollers and fine sanding rollers for different levels of surface finishing

Multi-stage roller combinations help achieve higher surface flatness and better sanding results

Abrasive Belt System

The sanding belts are looped over the rollers and rotate at high speed to grind the surface

Features automatic belt tensioning and tracking systems to maintain smooth, accurate belt movement

Dust Collection System

Equipped with dust hoods and air duct connections

Efficiently removes wood dust and particles generated during sanding, keeping the equipment and working area clean

Pressure Mechanism

Uses air cylinders or springs to press the boards down during sanding

Automatically adjusts pressure based on board thickness to prevent slipping or shifting

Electrical Control System

Includes PLC, touchscreen interface, buttons, and inverters

Controls the entire machine, allows parameter setting, and provides fault alarms

Some models also support auto-diagnosis and remote monitoring functions

Machine Frame & Safety Devices

Built with a heavy-duty frame structure to ensure stability during operation

Fitted with safety features such as emergency stop buttons, safety doors, and overload protection to safeguard operators

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.