In the evolving landscape of industrial woodworking, pressing plywood machines stand as critical assets—where efficiency, durability, and precision define production success. As global demand for high-performance machinery rises, Chinese manufacturers have solidified their position as leaders in innovation and cost-effective engineering. This 2026 review highlights the top eight pressing plywood machine manufacturers renowned for superior build quality, advanced automation, and proven reliability in large-scale operations. Sourced from a rigorous evaluation of performance metrics and market feedback, these suppliers represent the forefront of smart, scalable solutions for modern wood composites production.

أفضل 8 شركات مصنعة لآلات ضغط الخشب الرقائقي (مراجعة 2026)

(مرتبة حسب القدرة التقنية والسمعة في السوق)

#1 Hydraulic Press Manufacturers in India

الموقع الرسمي: srichakraengineering.com

We are one of the leading manufacturers and suppliers of wide varieties of hydraulic presses that are used in gamut of industrial applications….

#2 Plywood Press Machine

الموقع الرسمي: avanca.com

Plywood Hot Press Machine Veneer Laminating Machine for Plywood. Manufacturer/Factory & Trading Company / Piece FOB. 18,500 Pieces (MOQ). More. Main Products ……

#3 Plywood Making Machine, Plywood Production Line, Veneer …

الموقع الرسمي: ply-machine.com

نحن نوفر تصنيع وتخطيط آلات الخشب الرقائقي، والتصميم، وتصميم الأتمتة، وتكنولوجيا المعالجة، وصيغة الغراء، وما إلى ذلك، بما في ذلك تقشير القشرة الخشبية ...

#4 Raute

تاريخ التأسيس: 1908

الموقع الرسمي: raute.com

منذ عام 1908، تعتمد الشركات على Raute لتوفير الآلات التحويلية والخدمات التكنولوجية....

#5 Biesse

الموقع الرسمي: biesse.com

Biesse هي شركة دولية تنتج خطوط إنتاج وآلات ومكونات للمعالجة الصناعية للخشب والزجاج والحجر والبوليمرات والمواد المركبة....

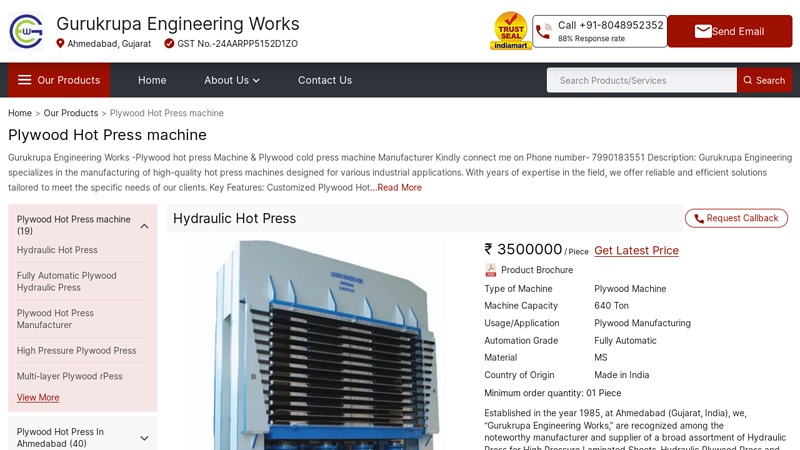

#6 Plywood Hot Press machine

الموقع الرسمي: gurukrupahydraulic.com

High Pressure Plywood Press · Power: 25 HP · Type of Machine: Plywood Machine · Machine Capacity: 640 Ton · Usage/Application: Plywood Manufacturing · Automation ……

#7 Hot Press Machine For Plywood Latest Price …

الموقع الرسمي: dir.indiamart.com

Automation Grade: Fully Automatic. Power: 20 HP. A plywood machine is a specialized piece of equipment used in the production of plywood, a widely used ……

#8 Hot Press Machine

الموقع الرسمي: plywoodmachineline.com

Hot press machine for pressing glued plywood, make it become one solid, strong and good quality board. Hot press machine are very important for plywood quality….

Professional Buying Guide: Pressing Plywood Machinery

2026 Global Pressing Plywood Market Trends: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global pressing plywood market is poised for significant transformation by 2026, driven by intense competitive pressures, rising operational costs, sustainability mandates, and evolving customer demands. Key technological and operational trends centered on الأتمتة، كفاءة الطاقة، الإنتاج عالي السرعة، وخفض تكاليف العمالة are converging to reshape manufacturing paradigms, creating a clear divide between leaders and laggards.

H2: Automation: The Cornerstone of Modern Plywood Pressing

Automation is rapidly transitioning from a competitive advantage to a fundamental requirement in 2026. The focus extends far beyond simple robotic loading/unloading.

- Integrated Digital Workflows: By 2026, leading mills will operate with fully integrated digital twins, connecting pre-press (lay-up, glue application, pre-pressing) seamlessly with the main hot press and post-press (trimming, sanding, sorting) lines. AI-powered systems will optimize press parameters (temperature, pressure, time) in real-time based on veneer moisture, glue viscosity, and target product specifications, minimizing defects and maximizing yield.

- Advanced Robotics & Vision Systems: Robotic systems equipped with sophisticated 3D vision and machine learning will handle complex tasks like precise veneer stacking, defect detection and rejection before pressing, and delicate handling of fragile or specialty core layers. This reduces human error and ensures consistent quality.

- الصيانة التنبؤية: Sensors embedded within press platens, hydraulic systems, and drive mechanisms will continuously monitor wear, vibration, and temperature. AI algorithms will predict component failures before they occur, enabling proactive maintenance, minimizing costly unplanned downtime, and extending equipment lifespan.

- التأثير: Automation directly drives labor cost reduction, enhances consistency, improves safety, and enables 24/7 operation. It is the primary enabler for achieving high-speed production sustainably.

H2: Energy Efficiency: A Critical Economic and Environmental Imperative

Energy consumption, particularly thermal energy for the hot press, represents a massive operational cost and a significant environmental footprint. By 2026, energy efficiency will be a major competitive differentiator.

- Advanced Press Design: Adoption of continuous presses (like continuous pressed veneer – CPV) will grow, offering inherently higher energy efficiency per unit of output compared to traditional multi-opening batch presses due to reduced heat loss and optimized heat transfer. Batch press manufacturers will offer models with superior insulation, heat recovery systems (capturing waste heat from press exhaust for pre-heating or building heating), and optimized platen heating/cooling cycles.

- دمج الطاقة المتجددة: Major players will increasingly invest in on-site renewable energy (solar, biomass from wood waste) or procure green energy to power presses and associated systems, driven by carbon pricing mechanisms, ESG reporting requirements, and customer demand for low-carbon products. Biomass boilers using wood residues will become standard for thermal energy.

- تحسين العمليات: AI-driven optimization will minimize energy waste by precisely matching press cycle times and temperatures to the specific panel requirements and real-time conditions, avoiding over-curing or inefficient heating/cooling phases.

- التأثير: Significant reduction in energy costs (often 20-40% of total production cost), lower carbon emissions, enhanced compliance with environmental regulations, and improved brand reputation.

H2: High-Speed Production: Meeting Demand with Precision and Control

The demand for faster throughput to meet growing global demand for plywood (especially in construction and packaging) necessitates high-speed production, but speed cannot compromise quality or safety.

- Faster Cycle Times: Automation and energy efficiency gains directly enable faster press cycles. Optimized glue systems (faster-curing resins, precise application) and advanced press control systems allow for shorter pressing durations without sacrificing bond strength.

- Continuous & High-Capacity Batch Presses: The shift towards continuous presses and high-opening (e.g., 20+ opening) batch presses with rapid opening/closing mechanisms will accelerate, maximizing output per hour. Efficient material handling systems (automated in-feed/out-feed) are crucial to support these speeds.

- Real-Time Quality Control (RQC): High-speed lines demand integrated RQC. Inline sensors (ultrasonic, X-ray, laser profilometry) will continuously monitor panel thickness, density, glue line integrity, and surface defects during or immediately after pressing, enabling instant feedback and adjustment to the process, preventing large batches of off-spec material.

- التأثير: Increased production capacity without proportional increases in floor space or labor, improved responsiveness to market fluctuations, and reduced work-in-progress inventory.

H2: Labor Cost Reduction: Beyond Simple Automation

While automation is a primary tool, labor cost reduction in 2026 encompasses a broader strategy focused on efficiency, skill optimization, and value.

- Automation as the Primary Driver: As outlined above, automating repetitive, physically demanding, and precision-critical tasks (loading, unloading, stacking, sorting, basic inspection) drastically reduces the headcount required on the pressing line.

- تطوير المهارات وتحويل الأدوار: The workforce will shift from manual labor to roles focused on monitoring automated systems, performing maintenance, programming, data analysis, and quality oversight. Investment in upskilling programs will be essential.

- Remote Monitoring & Operation: Cloud-based platforms will allow engineers and supervisors to monitor press performance, energy consumption, and quality metrics remotely, potentially managing multiple shifts or even different sites from a central location, reducing the need for constant on-site personnel.

- Improved Safety & Retention: Automation removes workers from hazardous environments (high heat, heavy loads, noise), improving safety. Combined with more skilled and engaging roles, this can lead to better employee retention, reducing turnover costs.

- التأثير: Significant reduction in direct labor costs per unit produced, mitigation of labor shortages (especially in high-wage regions), improved operational stability, and a more sustainable workforce model.

الاستنتاج لعام 2026:

The convergence of these four H2 trends – الأتمتة، كفاءة الطاقة، الإنتاج عالي السرعة، وخفض تكاليف العمالة – defines the future of the pressing plywood industry. Success will belong to manufacturers who strategically invest in integrated, intelligent systems. Automation enables speed and labor reduction, while energy efficiency ensures economic and environmental sustainability. High-speed production meets market demands, but only with the precision and quality control afforded by advanced automation and monitoring. Companies failing to embrace this technological shift risk becoming uncompetitive due to higher costs, lower quality, environmental non-compliance, and an inability to attract and retain a modern workforce. The 2026 pressing plywood leader will be defined by digitalization, efficiency, and sustainability.

How to Evaluate a High-Quality Pressing Plywood Machine

When assessing the quality and reliability of a pressing plywood machine, focus on the following critical check points to ensure long-term performance, efficiency, and minimal downtime:

متانة الهيكل الفولاذي

A robust steel frame is foundational to the machine’s stability and longevity. Inspect the pressing machine’s main structure for thick, high-tensile steel that resists deformation under continuous high pressure. Welded joints should be uniform and stress-relieved to prevent cracking. Look for corrosion-resistant finishes or coatings, especially in humid production environments. A well-engineered frame minimizes vibration during operation, ensuring consistent panel quality and reducing wear on other components.

ماركة المحرك (على سبيل المثال، Siemens/Mitsubishi)

The drive motors power the hydraulic and conveyor systems, directly impacting performance and reliability. High-quality machines typically use motors from globally recognized brands such as Siemens, Mitsubishi, ABB, or SEW. These brands offer superior efficiency, precise speed control, and longer service life. Verify the motor specifications and confirm authenticity—reputable manufacturers provide documentation and certification. Avoid machines with unbranded or generic motors, as they may lead to higher maintenance costs and operational failures.

نظام التحكم PLC

The Programmable Logic Controller (PLC) is the brain of the pressing system, managing cycle timing, pressure, temperature, and safety interlocks. Top-tier machines use PLCs from trusted manufacturers like Siemens (SIMATIC), Mitsubishi (MELSEC), or Omron. Assess the user interface for intuitiveness and real-time monitoring capabilities. Ensure the system allows for recipe storage, fault diagnostics, and remote troubleshooting. A reliable PLC enhances automation, reduces human error, and improves production consistency.

توافر قطع الغيار

Downtime can be costly, so readily available spare parts are crucial. Evaluate the supplier’s global or regional support network. Check if common wear components—such as seals, heating elements, sensors, and hydraulic valves—are stocked locally or can be quickly sourced. Preference should be given to machines that use standardized parts from major brands, as these are easier and faster to replace. Request a spare parts list and lead times during the evaluation process to ensure operational continuity.

Guide for Importing Pressing Plywood Machinery from China: Key Considerations

When importing pressing plywood machinery from China, it’s essential to verify several critical aspects to ensure smooth operation, safety, and long-term reliability. Below are key factors to evaluate before finalizing your purchase.

متطلبات الجهد الكهربائي (380 فولت/220 فولت)

Electrical compatibility is crucial when operating industrial machinery abroad. Chinese pressing plywood equipment is commonly manufactured for 380V three-phase power, which is standard in industrial settings in China. However, your local electrical infrastructure may differ.

- Verify Local Voltage Standards: Confirm whether your facility uses 380V, 220V, or another industrial voltage. In many countries, factories operate on 400V/230V (equivalent to 380V/220V), but variations exist.

- Request Voltage Customization: Specify your required voltage (e.g., 380V or 220V) when placing the order. Reputable Chinese suppliers can often customize the motor and control systems accordingly.

- Check Frequency (Hz): Ensure compatibility with your local power frequency (50Hz vs. 60Hz), as mismatched frequency can damage motors.

- Transformer Needs: If your site only has single-phase 220V power, confirm whether a step-up transformer is needed—and whether the supplier can provide or recommend one.

دعم التثبيت

Proper installation is vital for the performance and safety of pressing plywood machinery.

- خدمات التثبيت في الموقع: Inquire if the supplier offers technician dispatch for on-site installation. Many Chinese manufacturers provide this service, though it may incur additional costs (travel, labor).

- Remote Support Options: Confirm availability of remote support via video call or remote desktop to guide your local technicians through setup.

- Installation Manual & Diagrams: Request comprehensive installation manuals, wiring diagrams, and safety guidelines in English or your preferred language.

- Pre-Installation Checklist: The supplier should provide guidance on site preparation, foundation requirements, power connections, and ventilation.

شروط الضمان

A clear warranty protects your investment and ensures accountability.

- مدة الضمان: Standard warranties for pressing machines typically range from 12 to 24 months. Clarify the exact period and what it covers (e.g., mechanical parts, electrical components).

- نطاق التغطية: Determine whether the warranty includes labor, parts, and shipping for replacements. Some suppliers cover parts only, excluding international shipping and on-site service.

- الاستثناءات: Understand what voids the warranty (e.g., improper use, lack of maintenance, voltage mismatch).

- عملية المطالبة: Ask about the process for warranty claims—response time, required documentation, and how parts are delivered.

- خيارات الضمان الممتد: Check if extended warranty or service contracts are available for purchase.

مجموعة قطع غيار الشفرات والأجزاء

Downtime during production can be costly. Having spare parts on hand minimizes interruptions.

- Recommended Spare Kit: Request a recommended spare parts kit from the supplier. This typically includes:

- Extra pressing blades or rollers

- Belts, bearings, and seals

- Critical electrical components (e.g., fuses, relays)

- Wear-prone mechanical fasteners and joints

- التوافر والمهلة الزمنية: Confirm the availability of spare parts and average shipping time from China. Long lead times can disrupt operations.

- Pricing and Packaging: Ask for a bundled spare parts kit at a discounted rate. It’s often more cost-effective than ordering individually later.

- Compatibility Assurance: Ensure all spare parts are original or certified compatible with your machine model.

By addressing voltage specifications, securing reliable installation support, understanding warranty coverage, and stocking essential spare parts, you can ensure a successful and efficient integration of Chinese-manufactured pressing plywood machinery into your production line. Always communicate clearly with your supplier and document all agreements in writing.

In conclusion, sourcing a pressing plywood machine from China can offer significant cost advantages and access to advanced manufacturing technology. However, it is crucial to conduct thorough due diligence to ensure the quality, safety, and compliance of the equipment. A key step in this process is verifying that the machine carries a valid CE certification, which confirms that it meets European health, safety, and environmental protection standards. This not only ensures operational safety but also facilitates easier market access in regions requiring such compliance. Additionally, arranging for pre-shipment testing of the machine—either through a third-party inspection or by visiting the supplier’s facility—is highly recommended. This allows you to assess the machine’s performance, functionality, and build quality before it leaves the factory, minimizing the risk of receiving defective or substandard equipment. By prioritizing CE certification and rigorous pre-shipment evaluation, buyers can make informed decisions, reduce potential risks, and ensure a reliable, long-term return on investment.