As global demand for high-quality veneer processing rises, sourcing reliable veneer dryer machines has become critical for plywood and panel producers. In 2026, efficiency and durability remain top priorities—driving buyers toward manufacturers that combine advanced engineering with long-term performance. China’s position as a manufacturing powerhouse continues to strengthen, offering cost-effective, technologically sophisticated solutions that meet international standards. This review highlights the top seven veneer dryer machine manufacturers excelling in innovation, build quality, and consistent output—showcasing why Chinese-made equipment is increasingly trusted across the global woodworking industry.

أفضل 7 مصنّعين لآلات تجفيف القشرة الخشبية (مراجعة 2026)

(مرتبة حسب القدرة التقنية والسمعة في السوق)

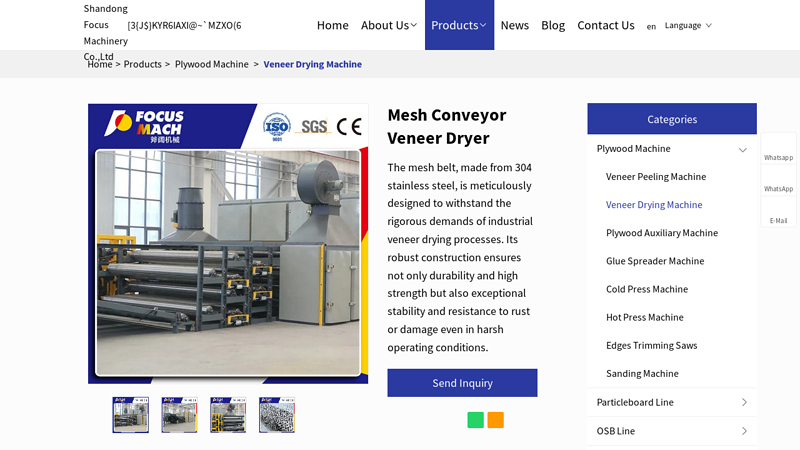

#1 China Mesh Conveyor Veneer Dryer Manufacturers Suppliers Factory

الموقع الرسمي: focus-mach.com

We’re well-known as one of the leading mesh conveyor veneer dryer manufacturers and suppliers in China. Please rest assured to buy high quality equipment ……

#2 China Manufacturer and Supplier of Plywood Veneer Dryer Factory …

الموقع الرسمي: tlplywood.com

China manufacturer and supplier of high-quality plywood veneer dryer. Visit our factory for top-notch drying equipment….

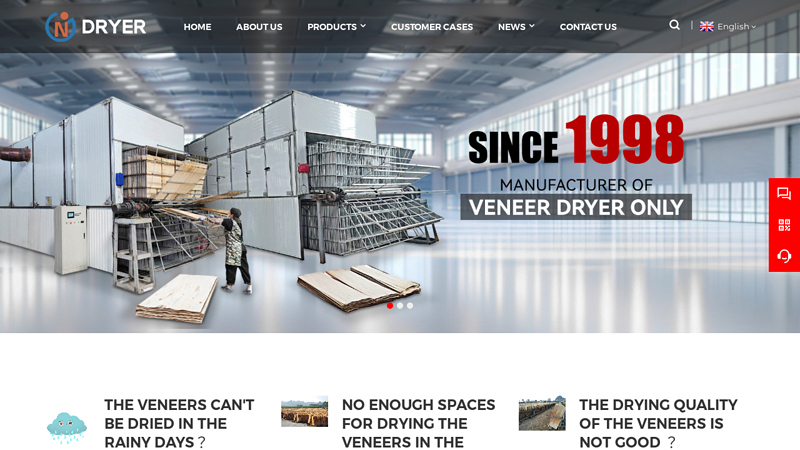

#3 China veneer dryer manufacturer, veneer drying machine supplier …

Founded: 1998

الموقع الرسمي: veneer-dryer.com

Shandong Linqu Juneng Drying Equipment Co.,Ltd. is a modern enterprise specializing in the R&D and production of different veneer dryers since 1998….

#4 China Veneer Dryers Manufacturers, Suppliers and Factory

الموقع الرسمي: hanvymachinery.com

As one of the leading veneer dryers manufacturers and suppliers in China, and equipped with a productive factory, welcome to import veneer dryers made in ……

#5 veneer roller dryer manufacturers plywood wood veneer drying …

الموقع الرسمي: yuequnmachinery.com

Rating 5.0 (42) veneer roller dryer manufacturers plywood wood veneer drying machine offered by China manufacturer Shandong Yuequn Machinery Co.,Ltd. Buy veneer roller ……

#6 Veneer Dryer Lines Seller

الموقع الرسمي: logpeeling.com

YIHONG is one of the most professional veneer dryer lines manufacturers and suppliers in China. Please feel free to buy used veneer dryer lines for sale ……

#7 China Top Veneer Dryer

الموقع الرسمي: plywoodmachineline.com

China Top Veneer Dryer- Roller Dryer & Mesh Dryer for Plywood factory ; Model: MH-VR40L ; Brand: MINGHUNG ; Code: 841939 ; Port: Qingdao port ; Production Capacity:….

Professional Buying Guide: Veneer Dryer In Machinery

2026 Global Market Trends for Veneer Dryers: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global veneer dryer market is poised for significant transformation by 2026, driven by intense pressure on manufacturers to enhance productivity, reduce operational costs, and meet increasingly stringent environmental and quality standards. Key technological and economic forces are converging, making advancements in الأتمتة، كفاءة الطاقة، الإنتاج عالي السرعة، وخفض تكاليف العمالة the central pillars shaping the future of this sector.

Automation: The Cornerstone of Modern Veneer Drying

By 2026, automation will transition from a competitive advantage to a fundamental requirement in high-performance veneer drying systems. Manufacturers are rapidly integrating:

* Intelligent Process Control Systems: Advanced PLCs and SCADA systems with AI-driven algorithms will continuously monitor and adjust temperature, humidity, air velocity, and conveyor speed in real-time based on sensor feedback (e.g., moisture meters, infrared cameras). This ensures consistent, optimal drying profiles for varying veneer species, thicknesses, and incoming moisture content, minimizing defects like checks, splits, or over-drying.

* Integrated Material Handling: Automated feeding systems (robotic arms, precision conveyors) and stacking/packaging solutions will become standard, creating seamless integration between the dryer and upstream/downstream processes. This reduces manual intervention and potential bottlenecks.

* الصيانة التنبؤية: IoT sensors embedded within dryers will monitor critical components (fans, bearings, burners, heat exchangers), enabling predictive analytics to schedule maintenance before failures occur, maximizing uptime and reducing costly unplanned downtime.

* المراقبة والتشخيص عن بُعد: Cloud-based platforms will allow operators and service technicians to monitor dryer performance, receive alerts, and perform diagnostics remotely, improving responsiveness and support efficiency.

التأثير: Automation significantly boosts product consistency, reduces scrap rates, improves overall equipment effectiveness (OEE), and lays the foundation for labor cost reduction.

Energy Efficiency: A Critical Driver for Sustainability and Cost Savings

With energy costs remaining a major operational expense and global decarbonization pressures mounting, energy efficiency is paramount:

* Advanced Heat Recovery Systems: By 2026, sophisticated multi-stage heat recovery (e.g., condensing heat exchangers, heat pumps) will be standard on new high-capacity dryers and retrofitted to older models. These systems capture waste heat from exhaust air and pre-heat incoming fresh air or process water, slashing fuel consumption by 25-40%.

* Optimized Heat Sources: Increased adoption of high-efficiency gas burners, biomass boilers (where sustainable fuel is available), and integration with renewable energy sources (e.g., solar thermal pre-heating, biogas) will diversify and green the energy mix. Electrification using renewable-powered heat pumps is emerging, especially in regions with favorable grids.

* Precision Airflow Management: Variable Frequency Drives (VFDs) on exhaust and supply fans will be ubiquitous, dynamically adjusting airflow based on drying stage and load, preventing energy waste from over-ventilation.

* Enhanced Insulation & Sealing: Improved thermal insulation materials and better sealing of dryer chambers will minimize heat loss to the surroundings.

التأثير: Energy-efficient dryers offer substantial operational cost savings (often paying back investments within 2-4 years) and are essential for meeting corporate sustainability goals and regulatory requirements.

إنتاج عالي السرعة: تلبية الطلب بدقة

The demand for higher output, particularly from large-scale plywood and LVL producers, is pushing the boundaries of drying speed without sacrificing quality:

* Optimized Drying Profiles: Leveraging automation and AI, dryers will implement highly dynamic, species-specific drying schedules that maximize drying rate while staying within safe stress limits, enabling faster throughput.

* Advanced Conveyance Systems: Robust, high-precision conveyor systems with minimal vibration and precise speed control will ensure stable, high-speed transport of veneer sheets through the drying chamber, reducing jams and breakage.

* Enhanced Heat & Mass Transfer: Design innovations in nozzle configurations, air distribution plenums, and chamber geometry will ensure more uniform and efficient heat and moisture transfer across the veneer surface, allowing for shorter residence times.

* Integration with High-Speed Peeling: Dryers will be designed as integral parts of high-speed veneer production lines, synchronized with advanced rotary veneer lathes capable of producing thin veneers at unprecedented speeds.

التأثير: High-speed dryers enable manufacturers to increase production capacity without proportional increases in footprint or labor, improving economies of scale.

Labor Cost Reduction: Achieving More with Fewer Personnel

Labor scarcity and rising wages, particularly in developed economies, are accelerating the shift towards highly automated, lean operations:

* Reduced Manual Oversight: Automation (sensors, AI control, remote monitoring) drastically reduces the need for constant manual monitoring, adjustment, and logging of drying parameters. Operators transition from “machine minders” to supervisors overseeing multiple lines.

* Minimized Manual Handling: Automated in-feed, out-feed, stacking, and packaging eliminate the most physically demanding and labor-intensive tasks associated with veneer drying.

* الصيانة التنبؤية: By reducing unplanned breakdowns and enabling efficient scheduling, maintenance labor requirements become more predictable and optimized, potentially requiring fewer specialized technicians on-site.

* Centralized Control Rooms: Modern control systems allow operators to manage multiple dryers and even entire production lines from a single centralized location, reducing the need for personnel physically present on the shop floor.

التأثير: Significant reduction in direct labor costs per unit of production, improved worker safety by removing personnel from hot, dusty environments, and mitigation of risks associated with labor shortages and turnover.

الخلاصة

By 2026, the global veneer dryer market will be dominated by highly automated, energy-optimized systems designed for high-speed, continuous operation with minimal labor input. Investment in these advanced dryers will be driven by the compelling economic case: substantial reductions in energy and labor costs, significant increases in production capacity and yield, and enhanced product quality and consistency. Manufacturers who fail to adopt these trends risk becoming uncompetitive due to higher operating costs and lower output flexibility. The convergence of automation, energy efficiency, speed, and labor reduction defines the future of efficient and sustainable veneer production.

Key Evaluation Criteria for a High-Quality Veneer Dryer

When selecting a high-quality veneer dryer, several critical factors must be assessed to ensure long-term reliability, performance, and operational efficiency. Below are the essential check points to consider:

متانة الهيكل الفولاذي

The structural integrity of the veneer dryer is fundamental to its longevity and safe operation. A high-quality dryer should feature a robust steel frame constructed from thick-gauge, corrosion-resistant materials such as galvanized or stainless steel. The frame must be designed to withstand high temperatures and continuous operation without warping or deformation. Reinforced joints and proper welding techniques are essential to maintain alignment and stability over time. Inspect for anti-rust coatings and ensure the structure supports all internal components securely, minimizing vibration and wear.

ماركة المحرك (على سبيل المثال، Siemens/Mitsubishi)

The performance and reliability of drive and fan motors significantly impact drying consistency and energy efficiency. Premium motor brands like Siemens, Mitsubishi, ABB, or SEW are indicators of high-quality engineering, offering superior efficiency, durability, and resistance to thermal stress. These motors typically come with better warranties, lower maintenance needs, and proven track records in industrial applications. Verify that the motor specifications match the dryer’s operational load and environmental conditions, and confirm authenticity through documentation and labeling.

نظام التحكم PLC

A sophisticated PLC (Programmable Logic Controller) system is crucial for precise temperature, speed, and humidity control throughout the drying process. Leading brands such as Siemens, Allen-Bradley (Rockwell), or Mitsubishi provide reliable, user-friendly interfaces with intuitive HMI (Human-Machine Interface) panels. The system should support programmable drying profiles, real-time monitoring, fault diagnostics, and data logging. Ensure the PLC is easily accessible for maintenance and software updates, and confirm compatibility with factory automation systems for future integration.

توافر قطع الغيار

Long-term operational efficiency depends on the ready availability of spare parts. Evaluate the manufacturer’s global or regional service network and their inventory of critical components such as heating elements, conveyor belts, rollers, sensors, and motor parts. Choose suppliers who provide comprehensive parts lists, clear documentation, and prompt delivery support. Machines backed by established brands typically offer better spare parts logistics, reducing downtime and maintenance costs over the dryer’s lifecycle.

By thoroughly assessing these four key areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can confidently select a high-performance veneer dryer built for reliability, precision, and long-term value.

Guide for Importing a Veneer Dryer from China

متطلبات الجهد الكهربائي (380 فولت/220 فولت)

When importing a veneer dryer from China, it is essential to verify the machine’s electrical specifications to ensure compatibility with your local power supply. Most industrial veneer dryers manufactured in China operate on 380 فولت، ثلاثي الطور، 50 هرتز, which is the standard industrial voltage in China. However, some models may be available in 220 فولت، أحادي الطور configurations for smaller operations or specific applications.

- تأكيد احتياجات الجهد الكهربائي: Verify whether your facility supports 380V 3-phase power. If you only have 220V single-phase, request a customized motor or voltage converter from the manufacturer.

- خيارات التخصيص: Many Chinese suppliers can modify the electrical system to match your regional standards (e.g., 480V/60Hz for North America). Specify your voltage requirements before placing the order.

- الامتثال الكهربائي: Ensure the machine includes appropriate safety certifications (such as CE or ISO) and comes with a detailed wiring diagram for local electrical inspection.

دعم التثبيت

Proper installation is critical to the performance and longevity of your veneer dryer. Evaluate the level of support offered by the Chinese supplier:

- خدمات التثبيت في الموقع: Some manufacturers offer technician dispatch for on-site setup, calibration, and startup assistance. This service may incur additional costs and require visa arrangements and travel logistics.

- الدعم عن بعد: Most suppliers provide video calls, manuals, and troubleshooting guides. Confirm availability in English or your preferred language.

- Foundation & Site Preparation: The supplier should provide detailed specifications for floor loading, ventilation, clearance, and utility connections (power, water, exhaust). Ensure your facility meets these prerequisites before shipment.

- المساعدة في التشغيل: Request that the supplier walk you through initial operation and drying parameter setup to optimize performance.

شروط الضمان

Warranty coverage varies significantly between Chinese manufacturers. Clarify the following before purchase:

- المدة: Standard warranties typically range from 12 إلى 24 شهراً from the date of shipment. Confirm whether the warranty covers parts, labor, or both.

- نطاق التغطية: Check if the warranty includes critical components like the heating system, conveyor, control panel, and motor. Consumables (e.g., rollers, belts) may be excluded.

- دعم الخدمة: Determine whether warranty repairs require returning parts to China or if local service is available through partners or third-party technicians.

- الاستثناءات: Damage due to improper installation, voltage mismatch, lack of maintenance, or unauthorized modifications is usually not covered.

- التوثيق: Ensure the warranty terms are provided in writing and included in the sales contract.

مجموعة قطع غيار الشفرات والأجزاء

To minimize downtime, it’s advisable to order spare parts along with the veneer dryer:

- مجموعة شفرات احتياطية: Includes extra drying blades or plates, especially important if your process involves abrasive veneer types. Confirm blade material (e.g., stainless steel) and compatibility.

- Common Spare Parts: Request a recommended spare parts kit that may include drive belts, heating elements, sensors, fuses, nozzles, and wear strips.

- التوافر والمهلة الزمنية: Ask about the supplier’s inventory and typical lead time for replacement parts. Stock critical spares locally to avoid production delays.

- قائمة أرقام القطع: Obtain a full parts list with diagrams and part numbers to simplify future reordering.

- Cost & Bundling: Spare kits are often offered at a discount when purchased with the main machine—take advantage of bundled pricing.

By carefully addressing voltage requirements, securing installation support, understanding warranty terms, and preparing spare parts in advance, you can ensure a smooth import and reliable operation of your veneer dryer from China.

In conclusion, sourcing a veneer dryer manufacturer from China can offer significant advantages in terms of cost-efficiency, technological capability, and production capacity. However, to ensure a successful and reliable procurement process, due diligence is essential. Buyers must prioritize manufacturers that provide valid CE certification, as this confirms that the equipment meets stringent European safety, health, and environmental protection standards—indicating a commitment to quality and compliance. Additionally, it is highly recommended to arrange for pre-shipment testing of the veneer drying machine, either through on-site visits or third-party inspections, to verify performance, functionality, and adherence to technical specifications. By emphasizing CE certification and thorough machine testing before shipment, buyers can mitigate risks, ensure product reliability, and establish a strong foundation for long-term partnerships with trusted Chinese manufacturers.