In today’s fast-paced woodworking and industrial sectors, maintaining peak cutting performance is critical. Automatic knife sharpening machines have become indispensable for ensuring operational efficiency, precision, and tool longevity. As demand for high-durability, low-maintenance solutions grows, Chinese manufacturers continue to lead with advanced engineering, cost-effective production, and scalable innovation. This 2026 review highlights the top nine manufacturers delivering reliable, high-performance automatic knife sharpening systems, combining cutting-edge technology with the robust manufacturing capabilities that have positioned China as a global hub for industrial machinery.

Top 9 Automatic Knife Sharpening Machine Manufacturers (2026 Review)

(Nach technischer Leistungsfähigkeit und Marktruf geordnet)

#1 Industrial Knife Sharpening Equipment

Offizielle Website: razoredgesystems.com

Razor Edge Systems manufactures central knife sharpening systems and related products for the meat processing industry for over 50 years….

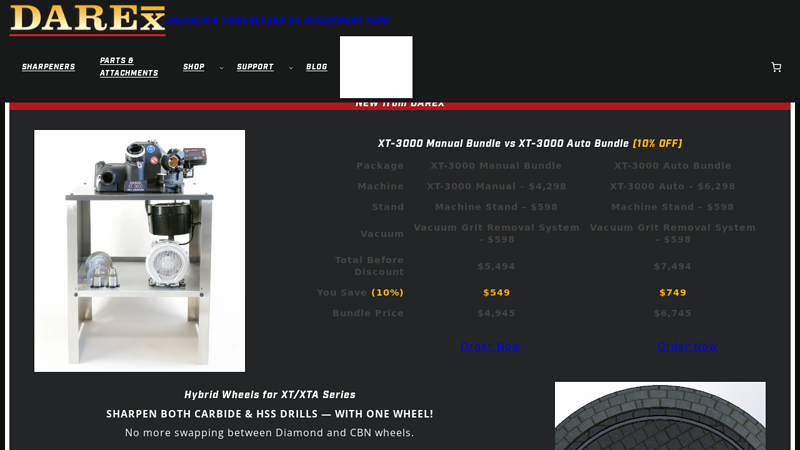

#2 Darex Industrial Drill Sharpeners

Offizielle Website: darex.com

30-day returns$6,895.00 The XT-3000 is available with an automated sharpening system. Assembled in the USA from US and imported parts….

#3 Automatic Knife Grinding Machine Woodworking Machinery Knife …

Offizielle Website: ply-machine.com

This machine is for grinding straight knife of veneer peeling machine, clipper, log debarker, slicer, etc. LMD-MZ7115 type knife grinder is specially for ……

#4 History

Offizielle Website: knecht.eu

Launch of the B 600 – the first unmanned, fully automatic cutter knife grinding machine. This computer-operated machine accommodates up to 20 knives in the ……

#5 KNECHT North America Inc.

Offizielle Website: knecht.us

The new hand knife sharpening machine EVO 5 – premium sharpness and maximum user-friendliness. The EVO 5 is a new development with the main focus on hand knives ……

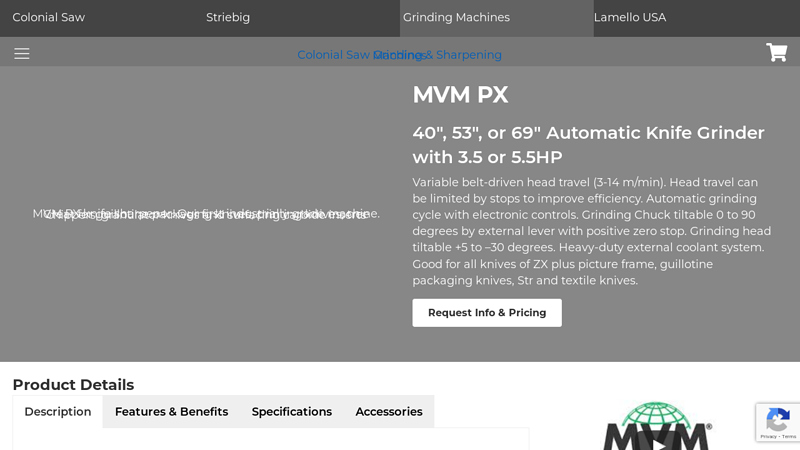

#6 MVM PX Automatic knife grinder and sharpen tree chipper knives

#7 Work Sharp

#8 Lansky Sharpeners

Offizielle Website: lansky.com

Lansky Sharpeners will sharpen anything from knives to gardening tools. Our selection of top-quality sharpening tools ensures precision and longevity….

#9 Wicked Edge Precision Knife Sharpeners

Professional Buying Guide: Automatic Knife Sharpening Machinery

2026 Global Market Trends for Automatic Knife Sharpening: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

Automation Driving Market Growth and Precision

Automation is emerging as the cornerstone of innovation in the automatic knife sharpening industry, with significant advancements expected by 2026. Manufacturers are increasingly integrating smart sensors, artificial intelligence (AI), and machine learning algorithms into sharpening systems to enable real-time blade assessment and adaptive grinding strategies. These technologies allow machines to automatically detect blade type, wear level, and optimal sharpening angles, minimizing human intervention and ensuring consistent, high-quality results.

In industrial kitchens, food processing plants, and manufacturing facilities, automated sharpening stations reduce downtime by enabling continuous operation. Fully robotic sharpening cells, capable of handling multiple blade types without manual setup, are being adopted by large-scale operations seeking operational reliability. The integration of Internet of Things (IoT) platforms allows for remote monitoring, predictive maintenance, and performance analytics, further enhancing automation benefits. As a result, the global market for automated knife sharpeners is projected to grow at a CAGR of over 6.5% from 2022 to 2026, with automation being a key driver.

Energieeffizienz als Wettbewerbsvorteil

Energy efficiency has become a critical differentiator in the design and marketing of automatic knife sharpening systems. By 2026, regulatory pressures and rising energy costs are compelling manufacturers to develop low-power consumption models that align with global sustainability goals. Newer models leverage variable-speed motors, regenerative braking systems, and optimized cooling mechanisms to reduce energy use by up to 30% compared to legacy systems.

Additionally, the shift toward eco-friendly materials and modular designs enables easier recycling and repair, extending product lifecycles and reducing environmental impact. Energy Star-rated and ISO 50001-certified sharpening equipment are gaining preference among commercial buyers, especially in Europe and North America, where green procurement policies are stringent. Companies investing in energy-efficient innovations are not only cutting operational costs but also enhancing brand reputation and compliance, positioning themselves as leaders in sustainable industrial tools.

High-Speed Production Meeting Demand for Throughput

The demand for high-speed automatic knife sharpening solutions is accelerating, particularly in food processing, packaging, and metal fabrication industries where blade turnover is high. By 2026, leading systems are expected to deliver sharpening cycles under 30 seconds per blade, driven by advancements in motor technology, abrasive materials, and robotic handling. High-speed production models incorporate dual or multi-station configurations, enabling parallel processing of multiple blades.

These systems are increasingly being integrated directly into production lines, allowing for in-line sharpening during scheduled maintenance windows or even continuous operation. The use of diamond-coated grinding wheels and CNC-controlled precision arms ensures rapid yet accurate edge restoration, minimizing blade degradation over repeated cycles. As industries prioritize uptime and throughput, the market for high-speed automatic sharpeners is expected to capture a growing share, especially in emerging economies with expanding manufacturing sectors.

Labor Cost Reduction Through Smart Operational Integration

Labor cost reduction remains a primary motivator for adopting automatic knife sharpening systems, particularly amid global labor shortages and rising wage expectations. By 2026, advanced systems will further diminish the need for skilled sharpening technicians by offering plug-and-play operation, intuitive touchscreen interfaces, and self-calibrating mechanisms. This democratization of sharpening technology allows untrained staff to maintain blades safely and efficiently.

Automated systems also reduce indirect labor costs associated with training, downtime, and blade mismanagement. Predictive analytics and maintenance alerts ensure optimal performance and prevent costly breakdowns. In large-scale operations, a single automated station can replace multiple manual sharpeners, delivering a return on investment within 12 to 18 months. As businesses across hospitality, healthcare, and manufacturing sectors seek leaner operations, the labor-saving benefits of automatic knife sharpening will remain a key purchasing criterion, fueling market expansion through 2026.

How to Evaluate a High-Quality Automatic Knife Sharpening Machine

When assessing the quality and long-term performance of an automatic knife sharpening machine, several critical factors must be examined. Paying close attention to the following check points ensures reliability, efficiency, and ease of maintenance in industrial or commercial applications.

Haltbarkeit von Stahlkonstruktionen

The structural integrity of the machine is foundational to its longevity and performance. A high-quality automatic knife sharpener should feature a robust steel frame constructed from thick, high-grade steel (such as stainless or reinforced carbon steel) to minimize vibration and maintain alignment during operation. Look for welded construction over bolted assemblies, as welding enhances rigidity and reduces wear over time. Additionally, powder-coated or corrosion-resistant finishes help protect against moisture and industrial contaminants, especially in demanding environments.

Motormarke (z. B. Siemens, Mitsubishi)

The motor is the powerhouse of the sharpening system, directly influencing precision and endurance. Reputable motor brands like Siemens or Mitsubishi are industry benchmarks for reliability, efficiency, and thermal protection. Machines equipped with motors from these manufacturers typically offer consistent rotational speed, higher torque, and longer service life. Verify that the motor specifications match the load requirements of your sharpening tasks and confirm whether the motor is appropriately rated for continuous duty cycles in industrial settings.

SPS-Steuerungssystem

A sophisticated PLC (Programmable Logic Controller) system ensures precise control over the sharpening process, including angle calibration, grinding speed, cycle timing, and error detection. High-end models use well-known PLC brands such as Siemens, Mitsubishi, or Omron, which provide stable performance, user-friendly interfaces, and programmable settings for different knife types. Evaluate whether the system supports data logging, fault diagnostics, and ease of programming—features that enhance operational efficiency and reduce downtime.

Verfügbarkeit von Ersatzteilen

Long-term usability depends heavily on the availability of spare parts. Choose a machine from a manufacturer or supplier with a strong service network and readily available replacement components—such as grinding wheels, belts, guides, motors, and PLC modules. Machines backed by comprehensive service agreements and global distribution channels ensure minimal downtime when maintenance or repairs are needed. Confirm lead times for critical components and whether the supplier maintains an accessible inventory.

Guide for Importing Automatic Knife Sharpening Machines from China

When importing automatic knife sharpening machines from China, it’s essential to consider technical specifications, installation support, warranty coverage, and spare parts availability. Below is a detailed guide addressing key aspects to ensure a smooth procurement and integration process.

Spannungsanforderungen (380 V/220 V)

Most industrial-grade automatic knife sharpening machines manufactured in China are designed to operate on either 380V (three-phase) or 220V (single-phase) power systems. Confirm the following before placing an order:

- Voltage Compatibility: Verify the machine’s voltage requirement matches your local electrical supply. Machines rated for 380V are typically used in industrial settings with three-phase power, while 220V models are suitable for smaller workshops or regions with single-phase power.

- Frequency: Check if the machine operates on 50Hz or 60Hz. China uses 50Hz standard, so ensure compatibility with your country’s power frequency.

- Customization Options: Reputable suppliers often offer voltage customization upon request. Confirm if a step-down or step-up transformer is needed and whether the machine can be factory-configured to your specifications.

- Plug and Wiring Standards: Ensure the machine comes with appropriate power connectors or wiring terminals compatible with your facility’s electrical setup.

Always request a detailed electrical specification sheet from the manufacturer to avoid compatibility issues upon delivery.

Installationsunterstützung

Proper installation is crucial for optimal performance and safety. Evaluate the level of support provided by the Chinese supplier:

- Installation vor Ort: Some suppliers offer on-site technician services for installation and commissioning, though this may incur additional costs. Clarify travel, labor, and duration terms upfront.

- Fernunterstützung: Many manufacturers provide detailed installation manuals, instructional videos, or real-time support via video call (e.g., Zoom, WeChat) to guide local technicians.

- Voraussetzungen vor der Installation: Confirm if the machine requires a stable foundation, compressed air supply, cooling systems, or specific workshop layout adjustments.

- Ausbildung: Ask if operator training is included—either on-site or through digital platforms—to ensure safe and efficient machine use.

Ensure installation support is clearly stated in the purchase agreement to prevent delays during setup.

Garantiebedingungen

Warranty coverage varies significantly between manufacturers. Clarify the following warranty details before finalizing the purchase:

- Dauer: Standard warranties typically range from 12 to 24 months, covering defects in materials and workmanship.

- Versicherungsumfang: Confirm whether the warranty includes electrical components, mechanical parts, motors, and control systems. Consumables (e.g., grinding wheels, belts) are usually excluded.

- Service und Reparaturen: Determine if warranty claims require returning parts to China or if local service centers or third-party technicians are authorized.

- Reaktionszeit: Ask about expected response and resolution timelines for warranty-related issues.

- Ausschlüsse: Be aware of conditions that void the warranty, such as improper installation, unauthorized modifications, or use with incompatible power sources.

Request a written warranty document in English and verify it aligns with your expectations.

Ersatzklingen-/Ersatzteilsätze

Maintaining an inventory of spare parts minimizes downtime. Consider these factors when sourcing spare blade and part kits:

- Availability: Confirm that the supplier offers comprehensive spare part kits, including grinding wheels, sharpening stones, drive belts, blades (if applicable), and wear-prone mechanical components.

- Pricing and Lead Time: Inquire about part prices and typical shipping times from China. Stock critical spares locally to reduce operational disruption.

- Compatibility: Ensure spare parts are model-specific and guaranteed to be compatible with your machine.

- Langfristige Unterstützung: Evaluate the supplier’s commitment to supporting the machine with spare parts over time, especially if it’s a specialized or custom model.

- Kit Options: Some suppliers offer pre-packaged maintenance kits at a discounted rate—ideal for routine servicing.

Maintain open communication with the supplier to receive timely updates on part availability and lifecycle support.

By addressing voltage requirements, installation support, warranty terms, and spare parts proactively, you can ensure a successful import and long-term reliability of your automatic knife sharpening machine from China.

In conclusion, sourcing an automatic knife sharpening machine from China can offer significant cost advantages and access to advanced manufacturing capabilities. However, to ensure product quality, safety, and compliance with international standards, it is essential to verify that the machine carries valid CE certification, confirming it meets European health, safety, and environmental requirements. Additionally, conducting thorough testing of the machine prior to shipment is crucial to validate its performance, durability, and functionality under real operating conditions. By prioritizing certification checks and pre-shipment inspections, buyers can mitigate risks, avoid potential compliance issues, and ensure a reliable and efficient sharpening solution that meets their operational needs.