As global demand for high-performance woodworking machinery grows, rotary dryers remain a critical component in optimizing production efficiency and material quality. In this 2026 review, we spotlight the top nine rotary dryer manufacturers shaping the industry with advanced engineering, exceptional durability, and cost-effective solutions. With China continuing to strengthen its position as a hub for precision manufacturing, these leading suppliers combine cutting-edge technology and scalable production to meet evolving international standards—delivering reliable, energy-efficient systems trusted by wood processing facilities worldwide.

Die 9 führenden Hersteller von Rotationstrocknern (Überblick 2026)

(Nach technischer Leistungsfähigkeit und Marktruf geordnet)

#1 Rotary Drum Dryer Manufacturers

Offizielle Website: baker-rullman.com

Baker-Rullman manufactures dehydration systems utilizing triple-pass rotary drum dryers for industrial, agricultural, and municipal applications….

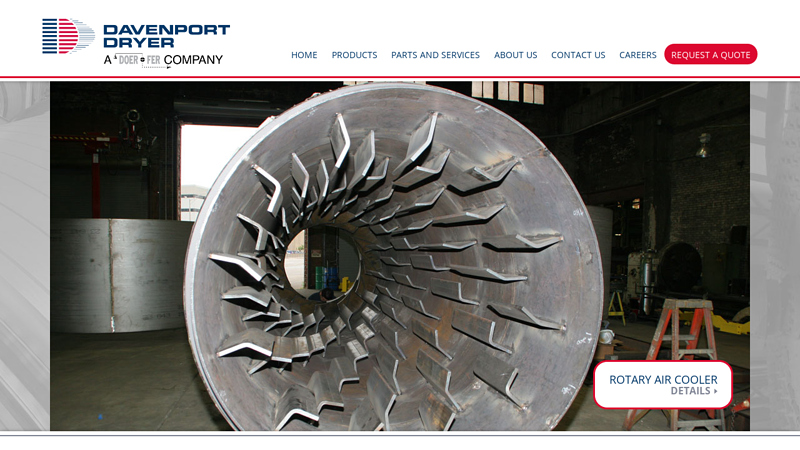

#2 Davenport Dryer

Offizielle Website: davenportdryer.com

Davenport Dryer, a division of Doerfer Companies is North America’s premier rotary dryer equipment supplier. Offering state of the art engineering, precision ……

#3 Rotary Drum Dryer Manufacturers

Offizielle Website: thoyu.com

Rotary Drum Dryer Manufacturers Manufacturers, Factory, Suppliers From China, For more information, please contact us as soon as possible!…

#4 Rotary Drum Repair, Rotary Dryer Equipment, Rotary Dryers …

Offizielle Website: precisionrotary.com

Precision Rotary specializes in rotary drum dryer repair, rotary design, rotary inspections & more. We provide rotary equipment & parts for frac sand plants ……

#5 Rotary Dryer Manufacturer

Offizielle Website: uzelacind.com

Uzelac Industries is a rotary dryer manufacturer based in Greendale, Wisconsin with rotary drying systems in operation worldwide….

#6 Louisville Dryer Company

Offizielle Website: louisvilledryer.com

Louisville Dryer Company manufactures custom rotary dryers & equipment for all industries, providing installation, maintenance, & optimization….

#7 FEECO International, Inc.

Offizielle Website: feeco.com

Rotary dryers offer a highly flexible solution to drying bulk solids ranging from specialty chemicals to minerals and ores. But with all this flexibility and ……

#8 Rotary Dryers

Founded: 1986

Offizielle Website: westec-america.com

Westec offers a full range of rotary dryers for a variety of uses. Since 1986, Westec America LLC has provided our customers with the highest quality rotary ……

#9 Grain Dryers

Offizielle Website: icminc.com

ICM rotary dryers are ideal for evenly dehydrating fine particles, especially those with combustion sensitivity. Operators in over 150 plants have benefited ……

Professional Buying Guide: Rotary Dryers Machinery

2026 Global Market Trends for Rotary Dryers: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

Automation Integration Driving Market Transformation

By 2026, automation will be a central pillar in the evolution of the global rotary dryer market. Manufacturers across industries such as food processing, chemicals, mining, and pharmaceuticals are increasingly adopting smart drying systems equipped with programmable logic controllers (PLCs), Internet of Things (IoT) sensors, and real-time monitoring capabilities. These technologies enable predictive maintenance, remote operation, and seamless integration with broader industrial automation platforms.

The push toward Industry 4.0 is accelerating the deployment of automated rotary dryers that can self-adjust parameters such as temperature, retention time, and feed rate based on real-time moisture content analysis. This level of automation not only improves process consistency but also reduces human error and downtime. Additionally, cloud-based data analytics allow operators to track performance across multiple sites, optimizing drying cycles and energy usage. As a result, demand for automated rotary dryers is projected to grow at a CAGR of over 7% from 2022 to 2026, with Europe and North America leading adoption due to mature industrial infrastructure.

Energy Efficiency as a Competitive and Regulatory Imperative

Energy efficiency is emerging as a decisive factor in rotary dryer procurement, driven by rising energy costs and stringent environmental regulations. By 2026, manufacturers are expected to prioritize dryers that utilize waste heat recovery systems, advanced insulation materials, and variable frequency drives (VFDs) to minimize energy consumption. Indirect rotary dryers, which separate the heat source from the product stream, are gaining traction due to their lower emissions and higher thermal efficiency compared to direct-fired models.

Regulatory frameworks such as the EU’s Ecodesign Directive and U.S. ENERGY STAR guidelines are pushing companies to adopt energy-optimized drying solutions. Additionally, carbon pricing mechanisms and corporate sustainability goals are incentivizing investments in energy-efficient technologies. Dryer systems incorporating renewable energy sources—such as solar thermal or biomass heating—are also entering niche markets, particularly in agriculture and food processing sectors in developing regions. By 2026, energy-efficient rotary dryers are expected to capture over 60% of new installations globally.

High-Speed Production Demands Reshape Dryer Design

The global shift toward high-throughput manufacturing is compelling dryer manufacturers to innovate for faster processing without compromising product quality. In response, next-generation rotary dryers are being engineered for higher rotational speeds, optimized flight designs, and enhanced material flow dynamics. These improvements enable shorter residence times and greater drying capacity per unit volume.

Industries such as mineral processing and biomass production, where large volumes must be processed continuously, are driving demand for high-speed rotary dryers. Advanced computational fluid dynamics (CFD) modeling is being used to fine-tune airflow and heat distribution, maximizing drying efficiency. Moreover, modular and scalable dryer systems allow quick deployment and adaptation to changing production needs. By 2026, high-speed rotary dryers are anticipated to represent over 45% of new installations in emerging markets like India, Southeast Asia, and parts of Africa, where industrialization is accelerating.

Labor Cost Reduction Through Smart and Autonomous Systems

Labor cost reduction remains a critical driver in the global rotary dryer market, especially in regions experiencing labor shortages or rising wage pressures. Automation directly contributes to lower operational staffing needs, with modern rotary dryers capable of running 24/7 with minimal human intervention. Fully automated systems reduce the need for manual monitoring, temperature adjustments, and maintenance scheduling.

Robotic material handling and automated cleaning systems are being integrated into dryer setups to further cut labor demands. In countries such as Japan, South Korea, and Germany, where labor costs are high and aging populations limit workforce availability, investments in autonomous drying lines are accelerating. Even in lower-cost labor markets, companies are adopting automation to improve safety, reduce turnover, and ensure consistent product quality. By 2026, it is estimated that automated rotary dryer systems will reduce labor requirements by up to 50% compared to conventional models, making them a compelling economic proposition across all regions.

In conclusion, the 2026 global rotary dryer market will be defined by a convergence of automation, energy efficiency, high-speed capabilities, and labor optimization. Companies that align their product development with these trends will hold a competitive edge in an increasingly technology-driven industrial landscape.

Key Evaluation Criteria for High-Quality Rotary Dryers

When assessing the quality and reliability of a rotary dryer, several critical factors must be considered to ensure long-term performance, efficiency, and minimal downtime. Below are the essential check points to evaluate:

Haltbarkeit von Stahlkonstruktionen

The structural integrity of the rotary dryer directly impacts its longevity and safety. A high-quality dryer should feature a robust steel construction designed to withstand high temperatures, mechanical stress, and corrosive environments. Look for:

- Thick-gauge carbon steel or stainless steel construction, especially in high-wear zones.

- Reinforced support rollers, riding rings, and trunnion wheels made from high-strength alloy steel.

- Proper welding techniques and heat treatment to reduce stress and prevent cracking.

- Anti-corrosion coatings or paint systems suitable for harsh operating conditions.

Motormarke (z. B. Siemens/Mitsubishi)

The motor is the heart of the dryer’s drive system. Reputable brands ensure reliability, energy efficiency, and reduced maintenance. Evaluate based on:

- Use of premium motor brands wie Siemens, Mitsubishi, ABB, or SEW, known for durability and global service networks.

- Appropriate motor power rating matched to the dryer’s load and operating conditions.

- Inverter-duty motors compatible with variable frequency drives (VFDs) for precise speed control and energy savings.

SPS-Steuerungssystem

An advanced control system enhances operational precision, safety, and automation. A high-end rotary dryer should include:

- Industrial-grade PLC (Programmable Logic Controller) from trusted manufacturers like Siemens (SIMATIC), Allen-Bradley (Rockwell), or Mitsubishi.

- HMI (Mensch-Maschine-Schnittstelle) for intuitive monitoring and control of temperature, rotation speed, feed rate, and alarms.

- Integrated safety interlocks and diagnostics for predictive maintenance and fault detection.

- Modular and scalable design allowing for future upgrades or integration into plant-wide control systems.

Verfügbarkeit von Ersatzteilen

Minimizing downtime is crucial for continuous operations. Ensure the supplier offers:

- Global or regional availability of critical spare parts such as seals, bearings, liners, gears, and burner components.

- Comprehensive spare parts list and recommended inventory for maintenance planning.

- Technical support and documentation (manuals, schematics) for easy troubleshooting and part replacement.

- Long-term supply commitment from the manufacturer or authorized distributors.

By thoroughly evaluating these four key areas—Haltbarkeit der Stahlkonstruktion, Motormarke, SPS-Steuerungssystem und Verfügbarkeit von Ersatzteilen—you can confidently select a high-quality rotary dryer built for reliability, efficiency, and sustained performance.

Guide for Importing Rotary Dryers from China: Key Considerations

When importing rotary dryers from China, it’s essential to address several critical factors to ensure smooth operation, compliance, and long-term reliability. Below are key areas to focus on during procurement and logistics planning.

Spannungsanforderungen (380 V/220 V)

Rotary dryers manufactured in China typically operate on 380V, 3-phase, 50Hz electrical systems, which align with standard industrial power in China. However, voltage requirements must match your local electrical infrastructure:

- Spannungskompatibilität bestätigen: Verify whether your facility uses 380V/400V (common in Europe, Asia, and many industrial zones) or 220V/240V (common in North America and some regions).

- Request Custom Electrical Configuration: If your site uses 220V or a different frequency (e.g., 60Hz), specify this requirement upfront with the supplier. Some manufacturers can reconfigure motor controls and wiring to suit your voltage.

- Include Voltage Transformers if Needed: If the dryer cannot be modified, budget for a step-down or step-up transformer to match your supply. Ensure the transformer capacity matches the dryer’s motor load.

- Check Plug and Connector Standards: Confirm the power inlet type and ensure compatibility with your facility’s outlets or hardwiring standards.

Installationsunterstützung

Proper installation is crucial for performance and safety. Clarify the level of support the Chinese supplier provides:

- Unterstützung bei der Installation vor Ort: Request if the supplier offers technician deployment for on-site installation, commissioning, and operator training. Note that travel and labor costs may apply.

- Fernunterstützung: Many suppliers offer video calls, manuals, and digital guides. Confirm availability of English technical documentation and real-time support via phone or email.

- Foundation and Layout Requirements: Obtain detailed installation drawings, including space requirements, foundation specs, and utility connections (power, gas, exhaust).

- Third-Party Installation Coordination: If the supplier doesn’t provide on-site support, plan to hire a local industrial mechanical contractor familiar with rotary dryer systems.

Garantiebedingungen

Warranty coverage can vary significantly between manufacturers. Be sure to negotiate and document clear terms:

- Standard-Gewährleistungsfrist: Most reputable suppliers offer 12 to 24 months from the date of shipment or commissioning.

- Versicherungsumfang: Confirm what is covered—typically motors, gearboxes, drums, and structural components. Wear items like blades, liners, and seals may be excluded.

- Ausschlüsse: Understand exclusions related to improper installation, misuse, lack of maintenance, or use with unapproved materials.

- Claims Process: Clarify how to file a warranty claim, including required documentation (photos, maintenance logs), response time, and repair/replacement logistics.

- After-Warranty Service: Inquire about ongoing technical support and spare parts availability post-warranty.

Ersatzklingen und Ersatzteilsätze

Having spare parts on hand minimizes downtime. Ensure your order includes or allows for easy procurement of critical components:

- Request a Spare Parts Kit: Ask the supplier to provide a comprehensive spare parts kit with initial purchase. This should include high-wear items such as lifting blades, scraper bars, seals, bearings, and fasteners.

- Blade Material and Design: Confirm blade material (e.g., stainless steel, abrasion-resistant steel) matches your material processing needs. Request replacement blade specifications for future orders.

- Parts List and Catalog: Obtain a detailed parts list with OEM part numbers to simplify future ordering.

- Stock Critical Components: Based on expected usage, stock additional blades, drive chain/belts, and burner components locally.

- Langfristige Verfügbarkeit: Confirm the supplier will maintain parts inventory for at least 5–10 years post-purchase, especially for custom or proprietary components.

By addressing voltage compatibility, installation support, warranty terms, and spare parts early in the procurement process, you can ensure a successful and efficient integration of your imported rotary dryer into your production line.

In conclusion, sourcing rotary dryers from manufacturers in China can offer significant cost advantages and access to advanced industrial equipment. However, ensuring product quality, safety, and compliance is paramount for long-term operational efficiency. Buyers must prioritize suppliers that provide valid CE certification, as this confirms that the rotary dryer meets essential health, safety, and environmental protection standards within the European Economic Area. Beyond documentation, it is crucial to insist on thorough pre-shipment testing of the machine under real operating conditions to verify performance, durability, and adherence to technical specifications. By combining rigorous certification checks with hands-on equipment testing, buyers can mitigate risks, ensure reliable operation, and make confident, informed purchasing decisions when sourcing rotary dryers from China.