In 2026, the global demand for high-performance veneer drying solutions continues to rise, driven by the need for efficiency, durability, and precision in wood processing. Chinese manufacturing has solidified its position as a leader in the woodworking machinery sector, combining advanced engineering with cost-effective production to deliver reliable, high-output equipment. This review highlights the top seven veneer drying operator machine manufacturers renowned for innovation, robust build quality, and consistent performance—making them trusted partners for industrial-scale operations worldwide.

Top 7 Venner Drying Opeator Machine Manufacturers (2026 Review)

(Nach technischer Leistungsfähigkeit und Marktruf geordnet)

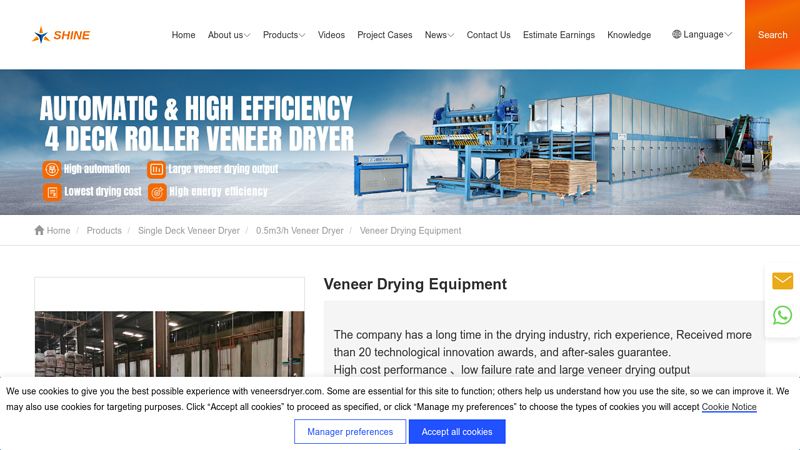

#1 Veneer Drying Equipment

Offizielle Website: veneersdryer.com

The company has a long time in the drying industry, rich experience, Received more than 20 technological innovation awards, and after-sales guarantee….

#2 Veneer dryer

Offizielle Website: ply-machine.com

Sinoeuro Machinery is a top supplier of Veneer dryer, many years, Our goal has always been to provide only the highest quality equipment and services.Missing: opeator manufacturer…

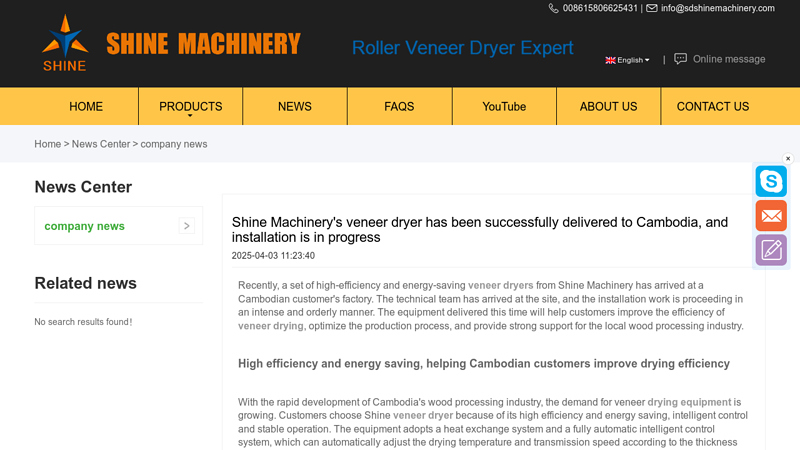

#3 Shine Machinery’s veneer dryer has been successfully delivered to …

Offizielle Website: woodveneerdryer.com

A set of high-efficiency and energy-saving veneer dryers from Shine Machinery has arrived at a Cambodian customer’s factory….

#4 Plywood & Veneer Solutions

Offizielle Website: sweed.com

From high-speed veneer dryer systems to automated panel handling, our equipment streamlines production, improves safety, and optimizes every phase of veneer and …Missing: venner factory…

#5 venner drying machinery opeator

Offizielle Website: accio.com

Find the best venner drying machinery opeator for veneer drying. Explore top-rated suppliers with automatic controls, PLC systems, and energy-saving tech….

#6 Veneer Drying Machine

Offizielle Website: focus-mach.com

Veneer dryer machine is a state-of-the-art equipment, it is used to remove excess moisture, this drum dryer can reduce the drying stage by 80%.Missing: venner opeator…

#7 Veneer Drying Technology

Offizielle Website: grenzebach.com

We offer everything from individual dryer plants with manual feeders, to complete veneer drying lines with automatic feeders, scanners and stacking systems….

Professional Buying Guide: Venner Drying Opeator Machinery

2026 Global Market Trends for Veneer Drying Operators: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

As the global wood processing industry evolves, Veneer Drying Operators are at the forefront of technological and operational transformation. By 2026, key market trends are shaping the sector—particularly in the areas of automation, energy efficiency, high-speed production, and labor cost reduction. These trends are driven by sustainability mandates, competitive pressures, and advancements in industrial technology. For Veneer Drying Operators, adapting to these shifts is critical to maintaining efficiency, reducing costs, and meeting increasing global demand for high-quality veneer products.

Automation: Revolutionizing Veneer Drying Processes

Automation is rapidly becoming the cornerstone of modern veneer drying operations. By 2026, an increasing number of drying facilities are integrating smart control systems, artificial intelligence (AI), and Internet of Things (IoT) platforms to monitor and optimize the drying process in real time.

Automated moisture sensors and feedback loops now enable precise control over temperature, humidity, and airflow within drying kilns, minimizing defects such as warping, cracking, or over-drying. Predictive maintenance systems powered by machine learning help prevent downtime by identifying potential equipment failures before they occur.

Additionally, robotic material handling systems are being deployed to load, unload, and sort veneer sheets with minimal human intervention. This not only improves throughput but also enhances worker safety by reducing exposure to high-temperature environments. As a result, facilities that adopt comprehensive automation are expected to see up to a 30% increase in operational efficiency by 2026.

Energieeffizienz: Erfüllung von Nachhaltigkeits- und regulatorischen Anforderungen

Energy efficiency has become a strategic imperative for Veneer Drying Operators, as drying accounts for a significant portion of energy consumption in veneer production—often exceeding 60% of total energy use.

By 2026, the industry is shifting toward low-energy drying technologies, including heat recovery systems, variable frequency drives (VFDs) on fans and blowers, and the use of renewable energy sources such as biomass, solar thermal, and heat pumps. Closed-loop drying systems that recycle exhaust heat are gaining traction, reducing energy consumption by up to 40% compared to traditional open systems.

Regulatory pressures in Europe, North America, and parts of Asia are pushing manufacturers to comply with stricter carbon emission standards. As a result, energy-efficient kilns certified under ISO 50001 or ENERGY STAR benchmarks are becoming a competitive advantage. Operators investing in energy-efficient drying technologies not only reduce operational costs but also improve their environmental, social, and governance (ESG) profiles—key factors for attracting green financing and premium market access.

High-Speed Production: Responding to Global Demand

The demand for engineered wood products, including plywood, laminated veneer lumber (LVL), and decorative veneers, is growing—particularly in construction, furniture, and interior design sectors across Asia-Pacific, North America, and Europe. This surge is driving the need for high-speed drying systems capable of processing larger volumes without compromising quality.

By 2026, continuous-motion drying lines with rapid airflow modulation and zone-controlled drying profiles are becoming standard. These systems can reduce drying cycles from days to mere hours, significantly increasing throughput. Advanced kiln designs with optimized airflow distribution allow for uniform drying of thinner and exotic veneer species, which are in higher demand for premium applications.

Moreover, integration with upstream and downstream processes—such as peeling, clipping, and gluing—via digital production lines ensures seamless material flow and minimizes bottlenecks. High-speed production capabilities are increasingly seen as a differentiator in competitive markets, enabling operators to meet just-in-time delivery requirements and scale operations efficiently.

Labor Cost Reduction: Optimizing Workforce and Operational Economics

Labor costs remain a significant concern, especially in regions with rising wages and labor shortages. By 2026, Veneer Drying Operators are leveraging technology to reduce dependency on manual labor through automation and digitalization.

Automated monitoring systems reduce the need for constant operator oversight, while centralized control rooms allow one technician to manage multiple drying lines simultaneously. Remote diagnostics and cloud-based platforms enable off-site troubleshooting and performance tracking, further reducing the need for on-site technical staff.

Training programs are also evolving, with augmented reality (AR) and virtual simulations being used to upskill workers more efficiently. This shift not only lowers hiring and training expenses but also improves workforce retention by making jobs less physically demanding and more technically engaging.

Operators who implement labor-saving technologies report reductions in labor costs by 20–35%, making their operations more resilient to wage inflation and labor market volatility.

Schlussfolgerung

By 2026, the global veneer drying sector will be defined by a convergence of automation, energy efficiency, high-speed production, and labor cost optimization. Veneer Drying Operators who proactively invest in these areas will gain a significant competitive edge, achieving higher productivity, lower environmental impact, and improved profitability. The future belongs to smart, agile, and sustainable drying operations that can adapt to evolving market dynamics and deliver consistent quality at scale.

Key Check Points for Evaluating a High-Quality Venner Drying Oven Operator

When assessing the quality and reliability of a Venner drying oven operator (or the operator’s competence in handling such equipment), it’s essential to focus on both the technical specifications of the equipment and the operator’s familiarity with critical system components. Below are key check points to consider:

Haltbarkeit von Stahlkonstruktionen

- Materialqualität: Verify that the oven’s frame and chamber are constructed from high-grade stainless steel (e.g., SUS304 or equivalent) to resist corrosion, thermal stress, and mechanical wear.

- Welding and Construction: Inspect for seamless welding, uniform thickness, and structural rigidity. Poor welds or thin gauge steel can lead to warping and reduced lifespan.

- Insulation Integrity: Ensure thick, high-density insulation (e.g., mineral wool or ceramic fiber) is used to minimize heat loss and maintain energy efficiency.

- Coating and Finish: A smooth, anti-rust coating on external surfaces enhances longevity, especially in high-humidity or corrosive environments.

Motormarke (z. B. Siemens/Mitsubishi)

- Brand Reputation: Confirm the use of trusted motor brands such as Siemens, Mitsubishi, ABB, or SEW. These brands offer superior reliability, efficiency, and thermal protection.

- Motor-Spezifikationen: Check for appropriate IP rating (e.g., IP55 or higher for dust and moisture resistance), duty cycle rating, and variable frequency drive (VFD) compatibility.

- Performance Monitoring: High-quality motors should support real-time monitoring of temperature, vibration, and load to prevent unexpected failures.

- Zertifizierungen: Look for motors with CE, UL, or other relevant international certifications indicating compliance with safety and performance standards.

SPS-Steuerungssystem

- PLC Brand and Model: Prefer systems using established brands like Siemens S7, Mitsubishi FX/Q series, or Allen-Bradley. These offer robust programming, diagnostics, and long-term support.

- Benutzeroberfläche (HMI): Evaluate the clarity and responsiveness of the touch screen interface. It should allow easy setting of temperature profiles, timer controls, and alarm management.

- Automation and Data Logging: Ensure the PLC supports programmable drying cycles, recipe storage, real-time data logging, and fault diagnostics.

- Integration Capability: Confirm compatibility with SCADA systems or factory MES for centralized monitoring and process optimization.

Verfügbarkeit von Ersatzteilen

- Lokale und globale Unterstützung: Verify that the manufacturer or supplier maintains a readily accessible inventory of critical spare parts (heaters, fans, belts, sensors, relays, etc.).

- Lead Time for Replacements: Short lead times (e.g., 1–2 weeks) for common components indicate better service support.

- Documentation and Labeling: Check that all parts are clearly labeled and that comprehensive spare parts lists with part numbers are provided.

- After-Sales Service Network: Assess the presence of local technicians, service centers, and technical support to minimize downtime during repairs.

By thoroughly evaluating these four critical areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can ensure both the reliability of the Venner drying oven and the operator’s ability to maintain optimal performance.

Guide for Importing Venner Drying Operator from China

Spannungsanforderungen (380 V/220 V)

When importing a Venner Drying Operator from China, it is essential to confirm the machine’s voltage compatibility with your local power supply. Most industrial units are configured for 380 V Drehstrom, which is standard in many manufacturing facilities globally. However, some models may support dual voltage configurations or offer 220V single-phase options for smaller operations or regions with different electrical standards. Before placing an order, verify the exact voltage specification with the supplier and ensure your facility can support the required electrical infrastructure. Request a detailed technical datasheet and consider using a voltage transformer if necessary, though this may impact performance and efficiency.

Installationsunterstützung

Ensure that your supplier provides comprehensive installation support to facilitate smooth commissioning of the Venner Drying Operator. This should include detailed installation manuals, wiring diagrams, and step-by-step setup instructions in English or your preferred language. Many reputable Chinese manufacturers offer remote assistance via video call or on-site technician services (at additional cost) to guide your team through the installation process. Confirm whether installation training is included and if engineers can assist with calibration and initial operation checks. Proactive communication with the supplier before shipment will help align expectations and avoid delays.

Garantiebedingungen

Review the warranty terms carefully before finalizing your purchase. Most suppliers offer a standard 12 Monate Garantie on the Venner Drying Operator, covering manufacturing defects and key components such as motors and control systems. Clarify what is included and excluded—typically, wear-and-tear parts (e.g., blades, belts) and damage from improper use or power surges are not covered. Confirm whether warranty service requires returning parts to China or if local service centers or replacement part shipments are available. Ensure that warranty claims can be processed efficiently, ideally with a responsive customer support team and clear documentation requirements.

Ersatzklingen-/Ersatzteilsätze

To minimize downtime, request a spare blade and maintenance parts kit at the time of purchase. These kits typically include extra drying blades, sealing gaskets, fasteners, and other commonly replaced components. Confirm the availability of spare parts for long-term support and ask about lead times for future orders. Reputable suppliers often provide part number lists and can supply kits at a discounted rate when bundled with the initial order. Maintaining an inventory of critical spares ensures operational continuity and extends the machine’s service life.

In conclusion, sourcing venner drying machinery operators from China can offer significant cost advantages and access to advanced manufacturing capabilities. However, it is crucial to prioritize quality, safety, and compliance to ensure long-term operational efficiency. Buyers must verify that the machinery comes with valid CE certification, confirming that it meets essential European health, safety, and environmental protection standards. Additionally, conducting thorough testing of the machine prior to shipment is essential to validate its performance, reliability, and adherence to agreed specifications. By emphasizing these precautions—CE certification verification and pre-shipment testing—purchasers can mitigate risks, ensure regulatory compliance, and secure a high-performing machine that supports seamless integration into their production processes.