In the competitive world of woodworking machinery, selecting the right wood rounder in machine is critical for maximizing production efficiency and ensuring long-term durability. As demand for precision and automation grows, Chinese manufacturers continue to solidify their position as leaders in innovation, quality, and scalable manufacturing. This 2026 review highlights the top seven wood rounder in machine manufacturers leveraging advanced engineering and robust construction to deliver high-performance solutions tailored for modern wood processing operations.

Top 7 Wood Rounder In Machine Manufacturers (2026 Review)

(Nach technischer Leistungsfähigkeit und Marktruf geordnet)

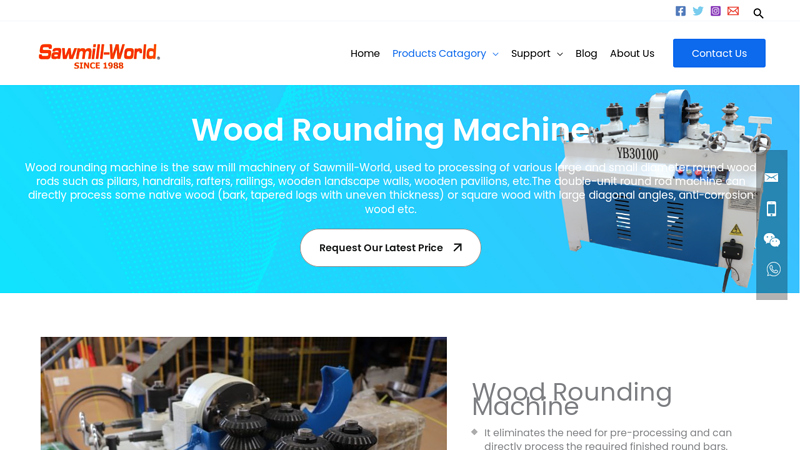

#1 Wood Rounding Machine of Sawmill

Offizielle Website: sawmillworld.com

Wood rounding machine is the saw mill machinery of Sawmill-World, used to processing of various large and small diameter round wood rods….

#2 CNC Wood Working Services

Offizielle Website: huahuacnc.com

Specialized in CNC woodworking machinery, HUAHUA provides one-stop solutions for your panel furniture manufacturing business. 2134232 1….

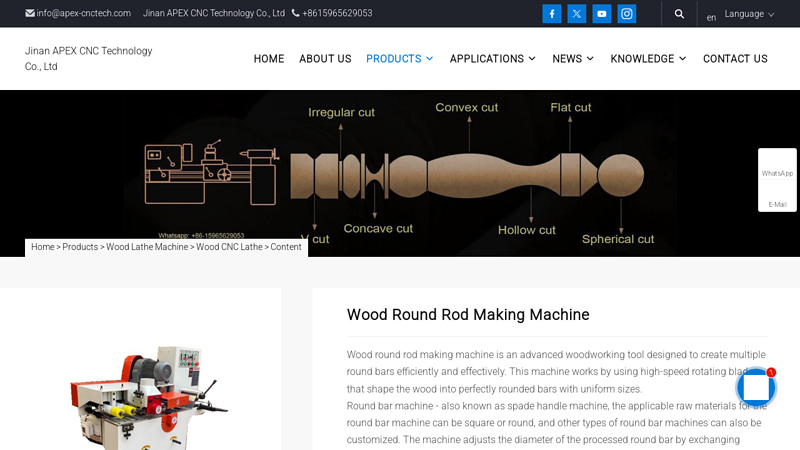

#3 Wood Round Rod Making Machine

Offizielle Website: can-cnc.com

As one of the most professional wood round rod making machine manufacturers and suppliers in China, we’re featured by quality products and good service….

#4 China Fully Automatic Dough Divider And Rounder Manufacturers …

Offizielle Website: taibomachine.com

We’re professional fully automatic dough divider and rounder manufacturers and suppliers in China, specialized in producing high quality food processing ……

#5 LANKOWOOD

Founded: 2000

Offizielle Website: lankowood.com

Lanko Wood Co.,Ltd, established in 2000 is a professional manufacturer for all types of wood boards. China’s largest wood producing, processing, and exporting ……

#6 Wood Products Manufacturers and Suppliers from China

Offizielle Website: lesprom.com

Qingdao (Shandong, China), SINOVO is a wood factory who producing kinds of flooring products. We have branch and investment in China mainland,southasia ……

#7 Top 10 Edge Banding Machine Manufacturer

Offizielle Website: bestingroup.com

Nanxing Machinery, a Chinese manufacturer, has gained international recognition for its affordable yet functional edge banding machines….

Professional Buying Guide: Wood Rounder In Machinery

2026 Global Market Trends for Wood Rounders: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

As the global wood processing industry evolves, the demand for high-performance Wood Rounders—machines used to shape square or rectangular timber into round profiles for applications such as columns, furniture legs, and decorative elements—is being reshaped by technological advancements and economic pressures. By 2026, key market drivers including automation, energy efficiency, high-speed production, and labor cost reduction are expected to define the competitive landscape for Wood Rounders worldwide.

Automation Integration Accelerates

Automation is rapidly becoming a cornerstone of modern wood manufacturing, and Wood Rounders are no exception. By 2026, manufacturers are increasingly integrating smart control systems, robotic feeding, and computer numerical control (CNC) technologies into Wood Rounder systems. These advancements enable seamless integration with upstream and downstream processes, such as log infeed, profiling, sanding, and packaging.

Artificial intelligence (AI) and machine learning algorithms are being employed to optimize cutting patterns and detect imperfections in real time, minimizing material waste. Fully automated Wood Rounder lines reduce human intervention, improve precision, and enhance consistency in finished products. This trend is particularly strong in North America and Western Europe, where labor shortages and high operational standards are pushing companies toward Industry 4.0 solutions.

Energieeffizienz als Wettbewerbsvorteil

Energy efficiency is emerging as a critical factor in the design and operation of Wood Rounders. With rising energy costs and stringent environmental regulations—especially under frameworks like the EU Green Deal and U.S. Clean Energy Initiatives—manufacturers are investing in energy-optimized motors, variable frequency drives (VFDs), and regenerative braking systems.

By 2026, new-generation Wood Rounders are expected to consume up to 25% less energy compared to models from the early 2020s. Machine designs now prioritize reduced friction, optimized spindle performance, and intelligent power management. Additionally, the integration of IoT-enabled monitoring allows operators to track energy usage and identify inefficiencies in real time. These improvements not only lower operational costs but also support sustainability goals, enhancing brand reputation and compliance with eco-certifications such as FSC and PEFC.

High-Speed Production Meets Customization Demand

The demand for faster throughput without compromising quality is driving innovation in high-speed Wood Rounder technology. By 2026, leading machines are expected to achieve production speeds exceeding 60 meters per minute, enabled by advanced spindle designs, high-torque motors, and improved tooling materials such as carbide-tipped cutters with longer lifespans.

High-speed capabilities are especially valuable in industries like modular construction and mass timber manufacturing, where standardized yet aesthetically refined round timber components are in growing demand. Moreover, modern Wood Rounders are becoming more adaptable, allowing quick changeovers between different diameters and profiles. This flexibility supports mass customization trends, enabling manufacturers to serve niche markets—such as luxury furniture and architectural millwork—without sacrificing efficiency.

Labor Cost Reduction Through Smart Manufacturing

Labor cost reduction remains a primary motivator for investment in advanced Wood Rounder systems. In regions facing skilled labor shortages—such as Germany, Japan, and the United States—automated Wood Rounders significantly reduce dependency on manual operators. By 2026, a single operator may oversee multiple machines through centralized control panels or remote monitoring systems.

The shift toward predictive maintenance, powered by sensor networks and cloud analytics, minimizes unplanned downtime and reduces the need for on-site technical staff. Furthermore, user-friendly interfaces and augmented reality (AR) support tools simplify operator training, lowering the skill threshold and reducing onboarding time. These efficiencies collectively contribute to a 30–40% reduction in labor-related expenses over the decade.

Schlussfolgerung

By 2026, the global Wood Rounder market will be defined by intelligent, efficient, and high-throughput systems engineered to meet the dual demands of productivity and sustainability. Automation, energy efficiency, high-speed operation, and labor cost optimization are no longer optional enhancements—they are fundamental requirements for competitiveness. Manufacturers that embrace these trends will lead the market, while those slow to adapt risk obsolescence in an increasingly automated and eco-conscious industry.

How to Evaluate a High-Quality Wood Rounder

When assessing a high-quality wood rounder, it’s essential to examine key components that influence performance, reliability, and long-term operational efficiency. Below are critical check points to consider:

Haltbarkeit von Stahlkonstruktionen

The steel frame of a wood rounder must be robust to withstand continuous vibration and heavy operational loads. Look for:

– Konstruktion aus dickwandigem, hochfestem Stahl that resists warping and deformation over time.

– Fully welded joints instead of bolted connections to enhance structural integrity.

– Korrosionsschutzbehandlung such as powder coating or galvanization, especially if operating in humid environments.

– A reinforced base design that minimizes vibration and ensures stable operation at high speeds.

A durable steel structure directly impacts machine longevity and precision in rounding operations.

Motor Brand and Performance

The motor drives the core functionality of the rounder, so choosing a reputable brand is crucial:

– Prioritize models equipped with motors from trusted industrial manufacturers wie Siemens, Mitsubishi, ABB, or Bosch.

– Verify the motor’s power rating (kW/HP) matches your production needs and wood density requirements.

– Überprüfen Sie, ob efficient heat dissipation, variable speed control, and overload protection features.

– Ensure the motor is compatible with your facility’s power supply (voltage, phase).

Motors from leading brands offer better energy efficiency, lower maintenance, and longer service life.

SPS-Steuerungssystem

Modern wood rounders should feature an advanced PLC (Programmable Logic Controller) system for precision and automation:

– Look for PLCs from established automation brands like Siemens S7, Mitsubishi FX/Q series, or Allen-Bradley.

– The control system should offer benutzerfreundliche HMI (Mensch-Maschine-Schnittstelle) with touchscreen capability for easy parameter adjustment.

– Ensure it supports preset programs for different wood diameters and lengths, enabling quick changeovers.

– Überprüfen diagnostic capabilities and error logging to reduce downtime and simplify troubleshooting.

A reliable PLC system enhances accuracy, repeatability, and production efficiency.

Verfügbarkeit von Ersatzteilen

Long-term maintenance and uptime depend heavily on spare parts accessibility:

– Confirm that the manufacturer or supplier maintains a readily available inventory of critical components (belts, bearings, cutters, sensors).

– Choose machines from brands with a strong local or global service network to ensure fast delivery of replacement parts.

– Check if worn parts are standardized or proprietary—standard parts are easier and cheaper to replace.

– Erkundigen Sie sich nach service support, technical documentation, and training availability.

Good spare parts logistics minimize downtime and reduce total cost of ownership.

By carefully evaluating these four areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can confidently select a high-performance, reliable wood rounder built for sustained industrial use.

Guide for Importing Wood Rounder In from China

Spannungsanforderungen (380 V/220 V)

When importing a Wood Rounder In machine from China, it’s essential to verify the voltage compatibility with your local power supply. Most industrial wood rounders manufactured in China are built to operate on 380 V, 3-phasig, 50 Hz, which is standard for Chinese industrial facilities. However, some models may offer dual-voltage options or can be customized to run on 220 V, einphasig power for smaller workshops or regions with different electrical standards.

- Confirm with the supplier whether the machine is configured for 380V or 220V.

- Request a voltage compatibility specification sheet before shipment.

- If your facility uses 220V, ensure the supplier can reconfigure the motor and control panel accordingly.

- Consider using a step-down transformer if 380V is not available, but note this may affect motor performance and efficiency.

Always inspect the machine’s nameplate and electrical schematics upon arrival to confirm the voltage rating matches your setup.

Installationsunterstützung

Reliable installation support is crucial for optimal performance and safety. Many Chinese manufacturers offer varying levels of assistance:

- Installationsservice vor Ort: Some suppliers provide technician dispatch for on-site setup and calibration for an additional fee.

- Fernsteuerung: Free support via video call, email, or phone to walk you through the assembly and commissioning process.

- Detailed Manuals: Comprehensive installation and operation manuals in English (or your preferred language) should be included.

- Pre-Assembled Units: Certain models ship nearly fully assembled, reducing setup time and complexity.

Clarify the scope of installation support during negotiations. Ask if training is included and whether additional costs apply for technical visits. Proactive communication with the supplier ensures a smoother setup process.

Garantiebedingungen

Warranty terms for Wood Rounder In machines from Chinese suppliers typically range from 12 bis 24 Monate, covering defects in materials and workmanship under normal operating conditions.

- Berichterstattung: Usually includes core components like the motor, gearbox, and frame. Consumables (e.g., belts, blades) may be excluded.

- Service-Antwort: Warranties often require customers to report issues promptly. The supplier may offer replacement parts or troubleshooting support.

- Ausschlüsse: Damage from improper use, lack of maintenance, or incorrect voltage is typically not covered.

- International Claims: Clarify how warranty claims are handled—whether parts are shipped internationally or if local service partners are available.

Request a written warranty document in English before purchase. Ensure it specifies response times, return shipping policies, and responsibilities for repair costs.

Ersatzklingen und Ersatzteilsätze

To minimize downtime, order spare blade and maintenance part kits at the time of purchase:

- Ersatzklingen: High-quality rounder blades wear over time. Purchase at least one full set of replacement blades; some suppliers offer carbide-tipped blades for longer life.

- Common Spare Parts: Kits may include belts, bearings, alignment tools, fasteners, and wear plates.

- Anpassung: Confirm blade dimensions and compatibility—some machines use proprietary blade designs.

- Bestandsplanung: Keep a 6–12 month supply of critical spares based on your usage volume.

- Supplier Stock: Verify that the supplier maintains spare parts inventory and can ship replacements promptly, even after the warranty period.

Ask the manufacturer for a spare parts catalog with part numbers and pricing to facilitate future orders. Establishing a long-term supply relationship ensures quick access to replacements.

In conclusion, sourcing a wood rounder manufacturer from China can offer significant cost advantages and access to advanced woodworking machinery, provided the process is approached with diligence and foresight. To ensure reliability, quality, and compliance with international safety standards, it is essential to verify that the manufacturer holds a valid CE certification—this demonstrates adherence to European health, safety, and environmental protection standards and is a strong indicator of product quality. Additionally, prior to shipment, arranging for thorough machine testing—either through on-site inspection or via third-party quality control services—is crucial to confirm that the wood rounder performs as specified and meets your operational requirements. Taking these steps not only minimizes risks but also ensures long-term satisfaction and performance, making your sourcing decision both strategic and secure.