In the fast-evolving woodworking machinery sector, debarker machines are essential for efficient log processing—where performance, durability, and precision matter most. As global demand rises, Chinese manufacturers continue to lead with advanced engineering, cost-effective solutions, and scalable production capabilities. This 2026 review highlights the top seven debarker machine manufacturers renowned for innovation, robust build quality, and reliable performance in high-throughput operations. Explore the key players shaping the future of wood processing with cutting-edge technology and proven results.

Top 7 Debarker Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Log Debarker Machine Manufacturers and Factory

Official Website: fandapelletmill.com

Fanda Machinery is one of the leading China log debarker machine manufacturers, providing the best quality equipment with competitive price….

#2 8 feet log debarker from China Manufacturers

Official Website: peeling-machine.goldsupplier.com

Explore 8 feet log debarker products at Shandong Jinlun Machinery Manufacturing Co., Ltd., reliable China manufacturer. Contact us for more details!…

#3 Debarker Manufacturer

Official Website: iem.ca

IEM manufacturers the best low maintenance, heavy duty, high capacity industrial debarkers. We manufacture debarkers for Sawmills, Pulp & Paper Mills, ……

#4 China Log Debarking Machine Manufacturers Suppliers Factory

Official Website: logpeeling.com

YIHONG is one of the most professional log debarking machine manufacturers and suppliers in China. Please feel free to buy used log debarking machine for ……

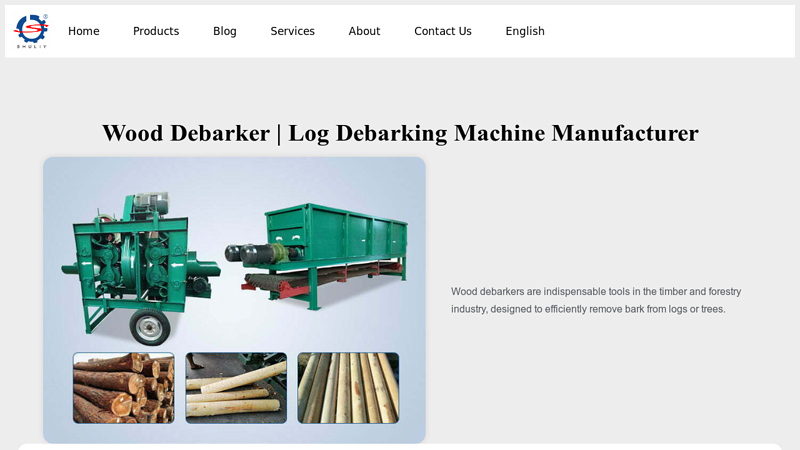

#5 Wood Debarker Log Debarking Machine Manufacturer Price

Official Website: woodmachine.org

Wood debarking machine can handle various types and sizes of wood. With its high debarking rate, it can quickly and effectively remove the bark, ……

#6 Debarker Machine for Manufacturing Wood Log Veneer from China …

Official Website: yuequnmachinery.com

Rating 5.0 (46) Debarker Machine for Manufacturing Wood Log Veneer · 1. Easy to operate and high production efficiency. Enlarged double roller and single roller. · 2. Reliable ……

#7 Nicholson Manufacturing

Official Website: debarking.com

Nicholson is committed to continually developing and building the world’s finest ring debarkers. Our teams of research and development engineers work closely ……

Professional Buying Guide: Debarker Machinery

2026 Global Market Trends for Debarkers: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

Automation Driving Smart Debarking Solutions

By 2026, automation is poised to be the cornerstone of innovation in the global debarker market. Manufacturers are increasingly integrating advanced automation technologies—such as artificial intelligence (AI), machine learning (ML), and Internet of Things (IoT) connectivity—into debarking systems to enhance precision, reduce operational downtime, and enable predictive maintenance. Automated debarkers equipped with real-time monitoring systems can detect log dimensions, bark thickness, and wood quality, adjusting cutting parameters dynamically for optimal performance. This shift is particularly evident in North America and Europe, where paper and pulp mills are adopting fully integrated smart factories. The adoption of robotic feeding and sorting systems further streamlines operations, minimizing human intervention and increasing throughput. As global demand for consistent timber quality grows, automated debarkers are expected to capture a significant share of new installations, especially in large-scale industrial facilities.

Energy Efficiency as a Competitive Advantage

Energy efficiency has become a critical differentiator in the debarker market, driven by tightening environmental regulations and rising energy costs. By 2026, manufacturers are prioritizing the development of energy-efficient debarking systems that reduce power consumption without compromising performance. Hydraulic and mechanical debarkers are being redesigned with variable frequency drives (VFDs), optimized rotor designs, and regenerative braking systems to lower energy use by up to 30%. Furthermore, water recycling systems and closed-loop cooling mechanisms are being incorporated to minimize resource consumption. Regions such as the European Union and Japan, with stringent sustainability mandates, are leading the adoption of eco-friendly debarkers. The integration of renewable energy sources—such as solar or biomass-powered systems—in remote logging operations is also gaining traction, positioning energy efficiency not just as a cost-saving feature but as a strategic component of corporate sustainability goals.

High-Speed Production to Meet Growing Demand

The demand for high-speed debarking solutions is accelerating in response to expanding global needs in the wood processing, pulp and paper, and biomass energy sectors. By 2026, high-throughput debarkers capable of processing over 200 logs per hour are becoming standard in modern facilities. Innovations such as multi-stage rotary drums, high-torque motors, and optimized flight designs enable faster processing with minimal wood loss. These systems are especially crucial in regions like Southeast Asia and South America, where rapid industrialization and rising consumption of wood-based products are driving mill capacity expansions. High-speed debarkers are also being designed for versatility, capable of handling diverse species and log sizes without significant reconfiguration. This flexibility, combined with increased speed, allows producers to maintain competitiveness in volatile markets by scaling output quickly and efficiently.

Labor Cost Reduction Through Technological Integration

Labor cost reduction remains a primary driver behind the technological evolution of debarkers. With rising wages and persistent labor shortages in key forestry regions—including Canada, the Nordic countries, and the U.S. Pacific Northwest—companies are investing heavily in debarking systems that minimize manual labor. Fully automated debarkers reduce reliance on skilled operators, decrease the risk of workplace injuries, and lower long-term operational expenditures. Remote monitoring and centralized control systems allow a single operator to manage multiple machines, further improving labor efficiency. Additionally, autonomous maintenance alerts and self-diagnostic features reduce the need for on-site technical personnel. As these technologies mature, the total cost of ownership for automated debarkers is expected to decline, making them accessible to mid-sized and emerging-market producers. By 2026, labor cost savings will be a decisive factor in procurement decisions, accelerating the global shift toward intelligent, low-labor debarking solutions.

In conclusion, the 2026 global debarker market will be defined by convergence across automation, energy efficiency, high-speed production, and labor cost reduction. Companies that integrate these elements into cohesive, scalable solutions will lead the industry, meeting both economic and environmental demands in an increasingly competitive landscape.

How to Evaluate a High-Quality Debarker

When selecting a debarker for industrial wood processing, several key factors determine long-term performance, reliability, and operational efficiency. Focus on the following critical check points to ensure you invest in a high-quality machine:

Steel Structure Durability

The structural integrity of the debarker directly impacts its lifespan and resistance to vibration and stress during operation. A high-quality debarker should feature:

- Heavy-duty welded steel frame constructed from thick-gauge, high-tensile steel to withstand continuous use.

- Reinforced support beams and bracing at stress points (e.g., drum supports, feed system mounts).

- Corrosion-resistant coating or paint treatment, such as sandblasting and epoxy priming, to prevent rust in humid environments.

- Evidence of design stability—minimal frame flexing or alignment issues after prolonged operation.

Motor Brand and Performance (e.g., Siemens, Mitsubishi)

The drive motor is central to consistent debarking performance. Reputable motor brands ensure reliability and energy efficiency:

- Recognized industrial motor brands such as Siemens, Mitsubishi, ABB, or Baldor are preferred for their proven durability and service support.

- Appropriate power rating matched to log volume and hardness (e.g., hardwood vs. softwood).

- Inverter-duty motors compatible with variable frequency drives (VFDs) for speed control and energy savings.

- Check for IP (Ingress Protection) rating—IP55 or higher for dust and moisture resistance in harsh environments.

PLC Control System

A sophisticated control system enhances automation, precision, and ease of operation:

- Industrial-grade PLC (Programmable Logic Controller) from leading manufacturers like Siemens, Mitsubishi, or Allen-Bradley.

- User-friendly HMI (Human-Machine Interface) with intuitive touch screen for monitoring and adjusting settings (e.g., drum speed, feed rate, cycle time).

- Programmable presets for different log types or diameters to streamline operations.

- Diagnostic capabilities and alarms for predictive maintenance and quick troubleshooting.

- Compatibility with factory automation systems (e.g., SCADA integration) for larger operations.

Spare Parts Availability

Ongoing maintenance and quick repairs are essential to minimize downtime:

- Confirm the manufacturer or supplier offers comprehensive spare parts inventory for critical components (e.g., debarking blades, bearings, chains, liners).

- Check global or regional distribution network—availability of parts locally reduces lead time.

- Look for standardized components that are easily replaceable and widely available.

- Request a spare parts list and pricing upfront, and verify service support responsiveness (e.g., technical assistance, field service).

By thoroughly evaluating these four key areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can confidently select a high-quality debarker that ensures reliable performance, lower operating costs, and long service life.

Guide for Importing a Debarker from China: Key Considerations

When importing a debarker from China, it’s essential to address several critical factors to ensure seamless operation, compliance, and long-term reliability. Below are the key aspects to evaluate before finalizing your purchase.

Voltage Requirements (380V/220V)

Ensure the debarker’s electrical specifications match your local power supply:

– Confirm whether the machine is configured for 380V (3-phase) or 220V (single-phase) operation.

– Most industrial debarkers from China are built for 380V/50Hz, which is standard in China but may differ from your country’s standards (e.g., 480V/60Hz in North America).

– Request a custom voltage configuration if needed—many Chinese manufacturers can adjust motor and control systems for export markets.

– Verify compatibility with your facility’s electrical infrastructure and consider hiring a local electrician for final connections.

Installation Support

Clarify the level of installation assistance provided:

– On-site installation: Some suppliers offer technician dispatch for setup (usually at an additional cost). Confirm travel fees, duration, and language support.

– Remote support: Many manufacturers provide installation manuals, wiring diagrams, and video guidance. Ensure documents are in English or your preferred language.

– Training: Ask if operator training is included—either on-site or via video call—to ensure safe and efficient machine operation.

– Pre-installation checklist: Request a list of site preparations (foundation, power, ventilation) to avoid delays.

Warranty Terms

Review the warranty carefully to protect your investment:

– Standard warranties typically cover 12 months from shipment, but terms vary by supplier.

– Confirm what is covered: mechanical components, motor, electrical systems, and labor (especially for international claims).

– Understand the claim process: Will parts be shipped quickly? Is on-site service available overseas?

– Note exclusions: Damage from improper installation, voltage mismatch, or lack of maintenance may void the warranty.

– Consider purchasing an extended warranty or service agreement for added peace of mind.

Spare Blade and Part Kits

Plan for maintenance and downtime reduction:

– Request a comprehensive spare parts list and pricing from the manufacturer.

– Purchase a starter spare kit that includes high-wear items like debarking blades, belts, bearings, and seals.

– Confirm blade compatibility and specifications (material, size, mounting type) to simplify future replacements.

– Ask about lead times for spare parts and whether local distributors or third-party suppliers can provide alternatives.

– Store critical spares on-site to minimize production interruptions.

By addressing these factors early in the procurement process, you can ensure a smooth import, installation, and long-term operation of your Chinese-manufactured debarker. Always communicate clearly with your supplier and document all agreements in writing.

In conclusion, sourcing a debarker machine from China can offer significant cost advantages and access to advanced machinery when done strategically. However, ensuring product quality and compliance with international safety standards is paramount. It is essential to verify that the machine carries a valid CE certification, which confirms adherence to European health, safety, and environmental protection standards. This not only minimizes legal and operational risks but also ensures the equipment meets rigorous performance requirements. Additionally, arranging for thorough on-site testing before shipment is strongly recommended to confirm the machine’s functionality, reliability, and readiness for operation. Taking these critical steps—validating CE certification and conducting pre-shipment testing—will help safeguard your investment, reduce downtime, and ensure a smooth integration of the debarker into your production process.