In the rapidly evolving world of industrial woodworking and composite production, lay up machines have become pivotal in ensuring precision, efficiency, and consistent output. As demand for high-performance solutions grows, manufacturers worldwide are turning to China—a hub of innovation and advanced manufacturing—for reliable, durable, and cost-effective machinery. This 2026 review highlights the top nine lay up machine manufacturers leveraging cutting-edge engineering and robust build quality to deliver exceptional operational efficiency and long-term durability. From automated systems to customizable configurations, these leaders exemplify the strength of Chinese manufacturing in meeting the evolving needs of global B2B buyers.

Top 9 Lay Up Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 Raute

Founded: 1908

Official Website: raute.com

Since 1908, companies have relied on Raute to deliver transformational machinery and technological services….

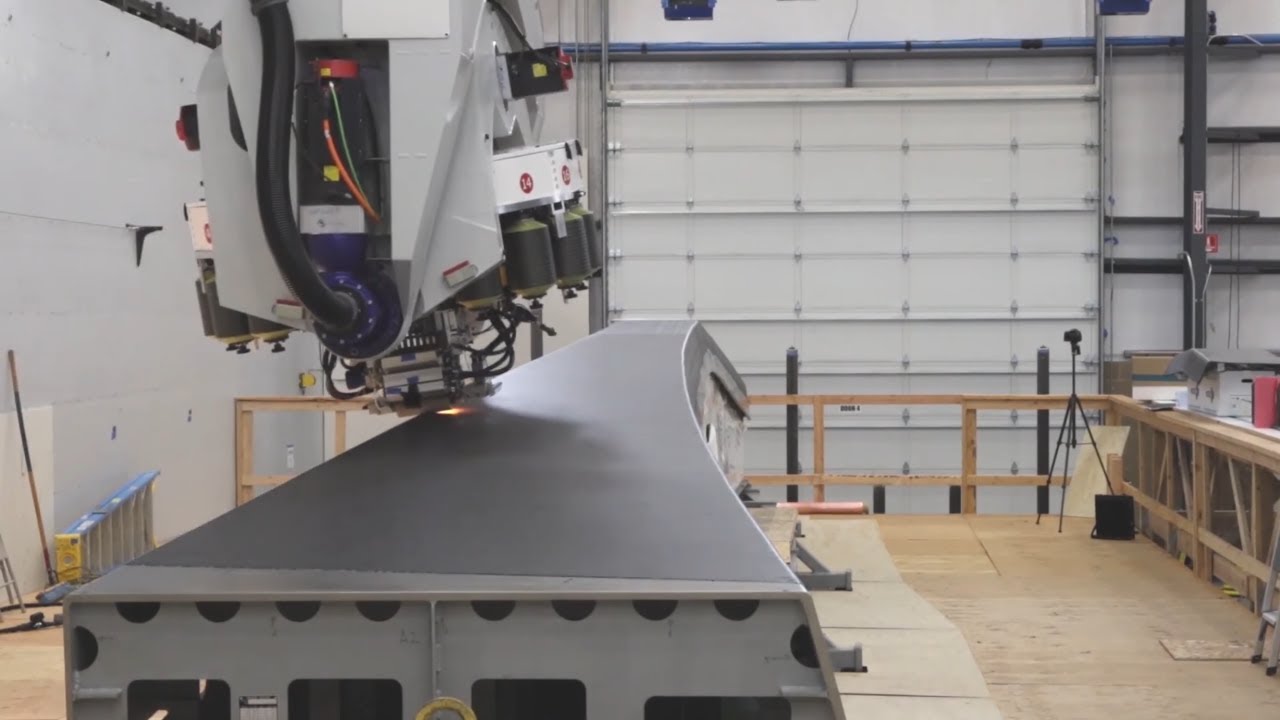

#2 Automated Fiber Placement

Official Website: toraycma.com

Toray Composites Materials America, Inc. (CMA) prepreg materials are available in varied configurations for a wide variety of automated layup equipment….

#3 Automated tape laying machines from Fives Group

Official Website: fivesgroup.com

Fives Group offers a leading range of automated tape laying machines focused on high precision, flexible performance and low scrap rates….

#4 Automated Tape Laying

Official Website: trelleborg.com

Automated Tape Laying (ATL) utilizes a single, wide, unidirectionally reinforced, slit tape to layup simple, gentle contours or flat parts….

#5 High Speed Solar Cell Stringer Layup Machine with Robot

Official Website: ooitech.com

Solar cell stringer layup machine is used to achieve solar string automatic laying on glass EVA, and transporting solar module to the next process….

#6 Solar Stringer Layup Machine for Solar Panel Production Lines

Official Website: solarmachineline.com

As a leading solar stringer layup machine supplier, Shuofeng specializes in manufacturing advanced lay up machine for solar panel production lines ….

#7 AI manufacturing software, composite and metallic molds and parts

Official Website: plyable.com

Wet Lay Up. Wet layup, also known as hand layup, is a more manual form of composite manufacturing where reinforced fibers are saturated with resin by a person ……

#8 Automatic taping machine

Official Website: mtorres.es

Valid for the layup of slit tape and fabrics. Perfect solution for automatic layup of Non-structural materials; Layup speed up to 140m/min; Automatic Scrap ……

#9 Layup Parts

Official Website: layupparts.com

Layup is reshaping the composites industry by utilizing technology to manufacture high quality composite parts faster and more affordable than anyone else….

Professional Buying Guide: Lay Up Machinery

2026 Global Market Trends for Lay-Up: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global lay-up market, encompassing composite manufacturing processes like hand lay-up, spray-up, and automated tape/laminate placement, is undergoing significant transformation driven by relentless pressure for efficiency, cost reduction, and sustainability. By 2026, the convergence of Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction will fundamentally reshape competitive dynamics across key industries like aerospace, automotive, wind energy, and marine.

Automation: The Primary Driver of Transformation

Automation is no longer a luxury but a strategic imperative in lay-up by 2026. Driven by labor shortages, quality demands, and the need for consistency, investment in robotic systems will surge.

* Robotic Lay-Up Dominance: Automated Tape Laying (ATL), Automated Fiber Placement (AFP), and robotic fiber spraying will see widespread adoption, particularly in aerospace and high-performance automotive. These systems offer micron-level precision, repeatability, and the ability to handle complex geometries impossible manually.

* AI & Machine Learning Integration: Automation will evolve beyond pre-programmed paths. AI will enable real-time defect detection (using integrated sensors and vision systems), adaptive path optimization based on material behavior, and predictive maintenance, minimizing downtime and scrap rates.

* Human-Robot Collaboration (Cobots): For smaller shops or complex final trimming/finishing tasks, collaborative robots will become more common, augmenting human workers for safer, more efficient hybrid processes.

* Impact: Automation directly addresses labor cost reduction and high-speed production, while also improving energy efficiency through optimized material usage and reduced rework. The initial investment barrier will decrease as technology matures and leasing/outsourcing models become more prevalent.

Energy Efficiency: A Critical Sustainability Imperative

Regulatory pressure, corporate ESG goals, and volatile energy costs will make energy efficiency a core competitive factor in 2026.

* Process Optimization: Manufacturers will focus on reducing the energy footprint of the entire lay-up and curing cycle. This includes optimizing oven/autoclave cycles (shorter ramps, lower peak temperatures where possible), improved insulation, and heat recovery systems.

* Material & Process Innovation: Development and adoption of low-temperature cure resins and out-of-autoclave (OOA) processes (like Vacuum Assisted Resin Transfer Molding – VARTM integrated with automated lay-up) will significantly reduce energy consumption compared to traditional autoclave curing.

* Renewable Energy Integration: Larger composite manufacturers, especially in wind energy supply chains, will increasingly power their facilities with renewable sources (solar, wind) to meet Scope 2 emissions targets, making energy costs more predictable.

* Impact: Energy efficiency reduces operational costs and carbon footprint, enhancing brand reputation and compliance. It’s intrinsically linked to cost reduction and sustainability, becoming a key differentiator.

High-Speed Production: Meeting Demand with Precision

The demand for composites in transportation (EVs, aircraft) and renewable energy (larger wind blades) necessitates significantly faster production rates by 2026.

* Faster Deposition Rates: Next-generation AFP/ATL machines and high-speed robotic spraying systems will achieve dramatically higher material deposition rates (e.g., meters per minute vs. centimeters per minute for manual lay-up).

* Reduced Cycle Times: Integration of lay-up with near-real-time in-process inspection (using inline NDI like ultrasound or thermography) allows for immediate correction, minimizing post-lay-up inspection bottlenecks and rework delays. Faster OOA curing cycles also contribute.

* Digital Twins & Process Simulation: Advanced simulation will be used to optimize lay-up sequences, tool paths, and cure cycles virtually, ensuring the fastest possible reliable production process is implemented on the factory floor.

* Impact: High-speed production is essential for scaling to meet market demand, particularly in cost-sensitive sectors like automotive. It directly reduces labor costs per part and improves capital utilization.

Labor Cost Reduction: A Persistent and Multifaceted Challenge

Rising wages, skilled labor shortages, and global competition make labor cost reduction a relentless focus, achieved through the other three trends.

* Automation as the Primary Tool: The most significant labor cost reduction comes from replacing manual lay-up operators with automated systems. While requiring skilled technicians for programming and maintenance, the overall labor count per part plummets.

* Upskilling & Role Transformation: The workforce will shift from manual laborers to technicians, programmers, data analysts, and maintenance specialists overseeing automated systems. This requires investment in training but leads to higher-value, more sustainable jobs.

* Geographic Optimization: For remaining manual or semi-automated processes, companies may still consider nearshoring or offshoring based on labor cost differentials, but this will be increasingly balanced against automation ROI, supply chain resilience, and quality control challenges.

* Impact: Labor cost reduction is the primary economic driver for adopting automation and high-speed production. It improves profitability and global competitiveness, but necessitates a strategic focus on workforce transformation.

Conclusion for 2026:

By 2026, the global lay-up market will be defined by integrated, intelligent automation. Success will hinge on the synergistic implementation of these four trends:

1. Automation will be the cornerstone, enabling the leap in speed and consistency.

2. High-Speed Production will be the direct outcome of advanced automation and process optimization.

3. Labor Cost Reduction will be the primary economic justification, achieved through automation and workforce transformation.

4. Energy Efficiency will be the critical sustainability and cost-control lever, intertwined with process and material innovations.

Manufacturers who fail to invest strategically in this integrated transformation risk significant competitive disadvantage. The future belongs to those who leverage technology not just to reduce costs, but to build smarter, faster, more sustainable, and more resilient composite manufacturing operations.

Key Checkpoints for Evaluating a High-Quality Lay Up Machine

When assessing the quality and long-term performance of a lay up machine—commonly used in glass, automotive, or composite manufacturing—several critical components must be evaluated. Below are the essential checkpoints to ensure reliability, efficiency, and minimal downtime.

Steel Structure Durability

The structural integrity of the lay up machine forms the foundation for precision and longevity. A high-quality steel frame ensures stability during operation and resistance to deformation over time.

- Material Quality: Verify the use of high-grade, anti-corrosion steel such as galvanized or powder-coated carbon steel.

- Frame Design: Look for a rigid, welded construction with reinforced joints to minimize vibration and maintain alignment.

- Load Capacity: Ensure the structure is engineered to handle the maximum weight and dynamic forces of the production process.

- Finish and Protection: A durable surface treatment (e.g., epoxy coating) protects against environmental wear, especially in humid or industrial environments.

Motor Brand and Performance (e.g., Siemens, Mitsubishi)

The motors drive the precision movements of the lay up system. Reputable brands ensure consistent performance, energy efficiency, and long service life.

- Brand Reputation: Prioritize machines equipped with motors from globally recognized manufacturers like Siemens, Mitsubishi, Yaskawa, or ABB.

- Precision and Control: High-quality servo or AC motors provide smooth operation and accurate positioning, essential for layer alignment.

- Maintenance Requirements: Premium motors typically require less maintenance and offer longer operational cycles between servicing.

- Energy Efficiency: Leading brands incorporate energy-saving technologies, reducing operational costs over time.

PLC Control System

The PLC (Programmable Logic Controller) is the brain of the lay up machine, governing automation, sequence logic, and fault diagnostics.

- Brand and Reliability: Opt for systems using established PLC brands such as Siemens S7, Mitsubishi FX/Q series, or Allen-Bradley.

- User Interface: A clear, intuitive HMI (Human-Machine Interface) allows for easy programming, monitoring, and troubleshooting.

- Customization and Scalability: The PLC should support customizable programs for different lay up patterns and be scalable for future automation integration.

- Diagnostic Capabilities: Advanced PLCs offer real-time error logging, remote access, and predictive maintenance alerts.

Spare Parts Availability

Long-term operational efficiency depends heavily on the accessibility of replacement components.

- Global Supply Chain: Machines built with standardized components from major suppliers (e.g., Siemens, Festo, SMC) ensure spare parts are readily available worldwide.

- Manufacturer Support: Evaluate the supplier’s after-sales service network, including inventory of critical spares and technical support response time.

- Modular Design: Systems designed with modular components simplify part replacement and reduce machine downtime.

- Documentation: Availability of detailed spare parts lists, exploded diagrams, and maintenance manuals streamlines procurement and repairs.

By thoroughly evaluating these four checkpoints—Steel Structure Durability, Motor Brand, PLC Control System, and Spare Parts Availability—you can confidently identify a high-quality lay up machine that delivers long-term reliability, precision, and cost-effective operation.

Guide for Importing Lay-Up Machines from China: Key Considerations

When importing lay-up machines from China, several critical factors must be addressed to ensure smooth operation, compliance, and long-term reliability. Below is a detailed guide focusing on voltage requirements, installation support, warranty terms, and spare parts availability.

Voltage Requirements (380V/220V)

Lay-up machines manufactured in China are typically designed to operate on 380V three-phase power, which is the standard industrial voltage in China. However, your local electrical infrastructure may differ.

- Confirm Voltage Compatibility: Before purchase, verify whether your facility uses 380V or 220V power. If your facility operates on 220V, request a machine configured for dual-voltage or equipped with a step-down transformer.

- Electrical Configuration: Ensure the machine supports your region’s frequency (50Hz or 60Hz). While most Chinese machines are built for 50Hz, some can be customized for 60Hz.

- Power Supply Modifications: If the machine requires 380V and your facility only has 220V single-phase power, you may need to install a three-phase converter or transformer—account for this in your budget and setup timeline.

- Request Documentation: Ask the supplier for detailed electrical specifications, including power consumption (kW), current draw (amps), and wiring diagrams.

Installation Support

Proper installation is crucial for optimal performance and safety. Clarify the level of support the supplier provides.

- On-Site Installation Services: Inquire if the supplier offers technician dispatch for installation and commissioning. This may incur additional costs but can prevent errors and downtime.

- Remote Assistance: If on-site support isn’t available, confirm whether the supplier provides video calls, detailed manuals, or real-time troubleshooting via phone/email.

- Installation Timeline: Coordinate delivery and installation timing. Allow buffer time for customs clearance and any required site preparation (e.g., floor reinforcement, power setup).

- Training: Request operator and maintenance training during installation to ensure your team can safely and efficiently use the machine.

Warranty Terms

Understanding the warranty protects your investment and ensures accountability.

- Warranty Duration: Standard warranties for industrial lay-up machines from Chinese suppliers typically range from 12 to 24 months. Confirm the exact period and what it covers.

- Coverage Scope: Clarify whether the warranty includes parts, labor, and shipping for repairs. Some suppliers exclude wear-and-tear components (e.g., belts, rollers).

- Service Response Time: Ask about the expected response time for warranty claims and whether repairs can be handled locally or require returning parts to China.

- Warranty Activation: Ensure you understand the documentation required (e.g., proof of purchase, installation report) to activate and maintain warranty coverage.

Spare Blade and Parts Kits

Downtime due to part failure can be costly. Proactive planning for spare parts is essential.

- Availability of Spare Kits: Request a recommended spare parts list, including blades, cutting heads, bearings, and control components. Many suppliers offer pre-packaged spare kits at the time of purchase.

- Blade Compatibility: Confirm that replacement blades are standardized or readily available from third-party suppliers to avoid dependency on the original manufacturer.

- Lead Time for Parts: Understand how long it takes to receive replacement parts from China, especially for custom or proprietary components. Consider stocking critical spares locally.

- Part Lifespan and Maintenance Schedule: Ask for expected lifespans of high-wear parts and recommended maintenance intervals to plan replacements and budget accordingly.

By addressing these factors upfront during supplier negotiations, you can ensure a smoother import process, reduce operational risks, and maximize the productivity of your lay-up machine.

In conclusion, sourcing a lay-up machine from China can offer significant cost advantages and access to advanced manufacturing capabilities. However, ensuring product quality and compliance with international safety standards is crucial for seamless integration into your production process. It is highly recommended to verify that the machine carries a valid CE certification, confirming that it meets EU health, safety, and environmental protection requirements. Additionally, arranging for a pre-shipment inspection or third-party testing can help identify any potential performance or safety issues before the machine leaves the supplier’s facility. These proactive steps not only mitigate risks but also ensure that the equipment performs reliably and safely upon arrival, safeguarding your investment and operational efficiency.