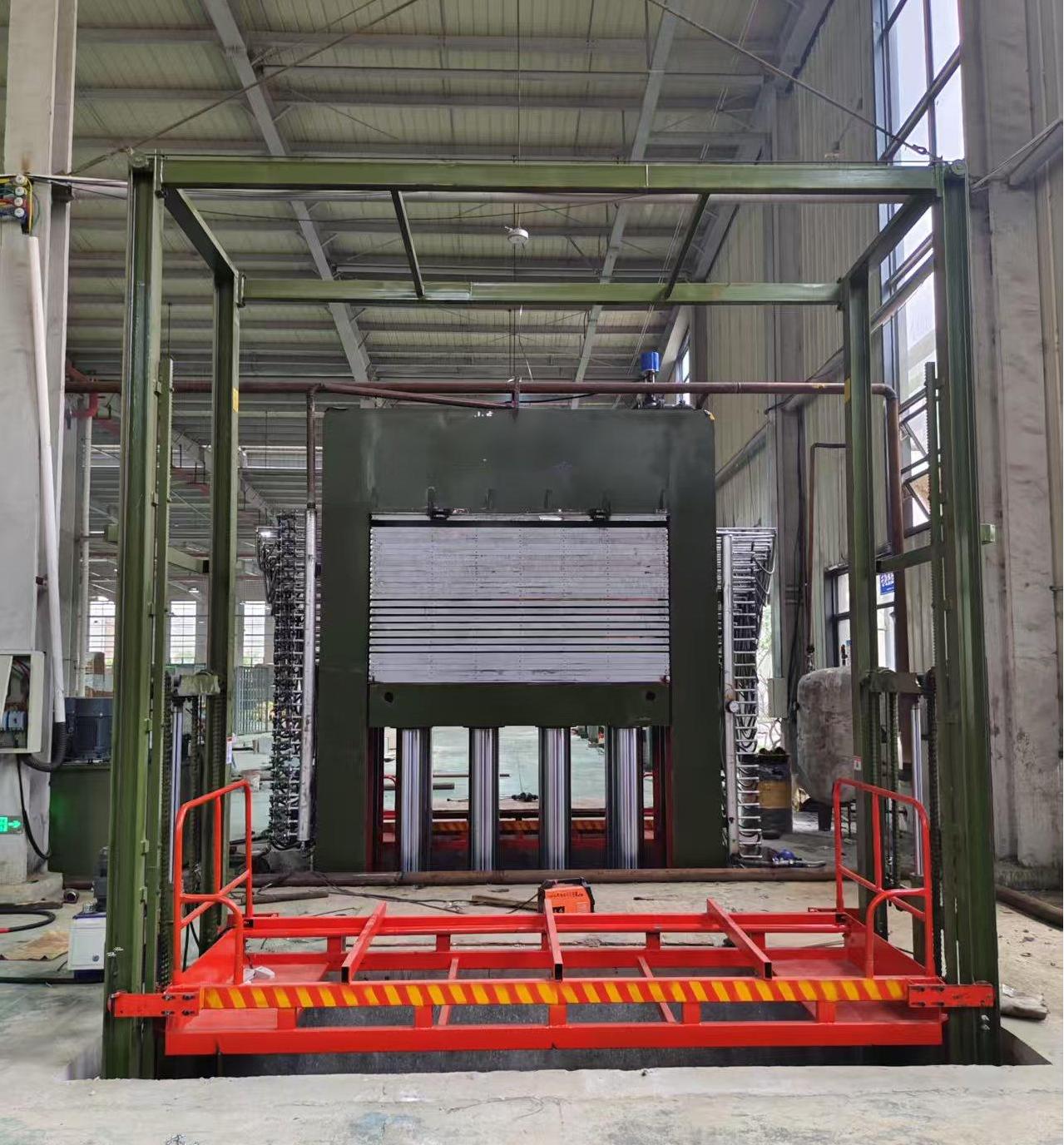

Nominal Pressure: 1500 tons

Layers: 25 layers

Layer Spacing: 70 mm

Hot Press Plates: 26 PCS

Plate Size: 2700 × 1370 × 52 mm (double in & double out)

Number of Plunger Cylinders: 8 pcs

Cylinder Diameter: 320 mm

Stroke: 1800 mm

Control System: Fully automatic control box

Pressure per Board : 10 kgf/cm²

Weight: Approx. 76 tons

Container Flooring Plywood is a type of high-strength plywood specially designed for manufacturing container floors, classified as a special industrial plywood. The main difference between it and ordinary plywood lies in its strength, durability, and resistance to harsh environments.

High Load-Bearing Capacity:

The payload of containers, whether 20GP or 40HQ, is around 28 tons net weight. The load per square meter needs to be 1–2 tons, but in practice, the higher design standard is required. Commonly, container floors are designed to withstand 1.8–2.5 tons/m².

Premium Raw Materials:

Hardwood, such as keruing wood, is often used as the core material. Its dense fibers ensure strong bonding between layers, excellent compressive and wear resistance, meeting the heavy load and durability requirements of containers.

Waterproof Adhesive:

Phenolic glue is used for hot-pressing, providing excellent water, moisture, and weather resistance, ensuring the plywood does not delaminate or lose adhesion under high temperature, humidity, or salty conditions.

Wear and Corrosion Resistance:

The surface is treated for anti-slip, increasing friction to prevent cargo from sliding, while also offering resistance to corrosion and abrasion.

High Output Efficiency

25 openings allow multiple thick boards (≈28mm) to be pressed at the same time, ensuring large-scale and stable production capacity.

Consistent Quality

With 26 hot plates, every layer receives even heat and pressure, guaranteeing uniform curing of glue and stable bonding across all boards.

Container floors are much thicker than ordinary plywood (≈28mm) and often require multiple core layers,the stroke of 1800 mm allows the press to accommodate very thick stacks, ensuring all layers are pressed simultaneously.

Large stroke combined with multi-layer pressing ensures uniform pressure across all layers, even in thick stacks, preventing delamination.

High rigidity prevents bending or deformation under high nominal pressure (1500 tons),Maintains consistent pressure across the entire panel, critical for heavy-duty flooring

Container floors are thick,Thick, rigid hot press plates and beams ensure the press can handle multi-layer stacks without sagging, ensuring strong, reliable panels.

Rapid platen closing reduces cycle time, increasing production efficiency.

Automatically monitors and controls pressure, temperature, and pressing time for each layer,Ensures consistent curing of glue and uniform board density, reducing defects like delamination, bulging, or uneven thickness.

Essential for thick or multi-layer boards (e.g., 25-layer container flooringallow low-pressure pumps allow gradual pressure increase, ensuring glue penetrates every layer,which is essential for thick or multi-layer plywood boards (e.g., 25-layer container flooring.

High-Pressure Pumps Prevent middle layer looseness or edge delamination,Ensure board density and load-bearing capacity

Dual Pump & Motor System Provide stable oil supply, fast response, and sufficient power for continuous high-load operation

Supports Large & Thick Panels,suitable for container floors (≈28 mm × 2700 × 1370 mm),and can handle multi-layer stacks without sagging

Rigid frame reduces vibration, extends equipment lifespan, and ensures consistent, high-quality production

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.