Wood Species & Veneer Size: Eucalyptus, suitable for 4×8 ft and 2×4 ft veneer

Veneer Thickness: 1.6mm

Veneer Moisture Reduction: From approx. 50% (fresh) down to 8–12%

Overall Dimensions: Approximately 53m (L) × 9m (W) × 3m (H)

Total Weight: Around 100 tons

Technical Parameters

Working Width: 3000mm

Decks: 2

Roller Material: Q235B, φ89 steel pipe

Heating Area Length: 44 meters

Cooling Area Length: 4 meters

Heating Material & Drying Temperature: Uses waste wood as fuel; temperature adjustable between 140–180°C

Veneer Transport Speed: 5–22 meters per minute, driven by 16A chain

Motor power:

Hot Air Blowers: 5.5KW × 11 units

Traction Motors: 7.5KW × 2 units, frequency-controlled

Cold Air Blower: 5.5KW × 1 unit

Air Intake Fans: 11KW × 2 units

Biomass Burner (6 Ton): 16.5KW

Total Installed Power: 119.5KW

Actual Electricity Consumption: About 80 kWh per hour

Our Features:

This dryer uses a wood burner furnace, unlike steam or oil type dryers.

The burner furnace provides high-temperature hot air for drying.

It has a thermal efficiency of 75%–85%, which means it uses energy very well and saves costs.The burner provides stable, high-temperature heat.

The furnace burns low-cost fuels like wood, wood chips, rice husks, and biomass pellets.

It works especially well with continuous roller conveyor dryers.

Ideal for large-scale, efficient drying of veneer.

Product Details Show

High-Strength Roller Structure

Uses φ89mm special shaft pipes with a wall thickness of 3mm and a center spacing of 180mm between rollers, ensuring stable and smooth veneer conveying.

Wood Waste Burner

Burns crushed bark and other biomass directly. It’s energy-saving, eco-friendly, and greatly reduces drying costs. Ideal for wood factories using their own waste. Compared to steam or thermal oil dryers, it operates 40–60°C hotter (140–180°C), drying faster and boosting output.

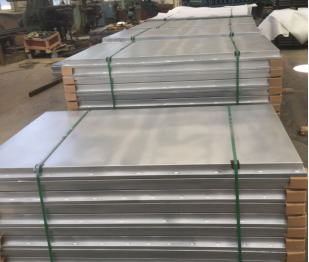

Efficient Insulation System

The side insulation panels are 60mm thick, made with 1.2mm galvanized sheets and lined with aluminum silicate blanket.

The top panels are 75mm thick and lined with rock wool composite boards for improved thermal insulation.

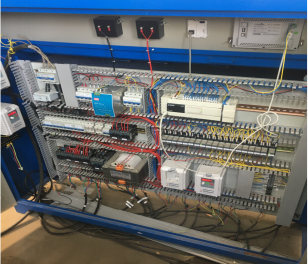

Smart Control System

With smart control, the machine automatically adjusts running speed and drying temperature according to the veneer’s thickness and moisture level.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.