A Fully Automatic Plywood Veneer Production Line is a set of machines that automatically process raw logs into thin wood sheets called veneers. It completes all steps—from feeding logs, removing bark, shaping, peeling, to sorting and stacking—reducing manual work. This system ensures efficient production of high-quality veneers with consistent thickness and minimal waste.

Loading Log Conveyor Machines

Maximum Loading Diameter: 600 mm

Loading Speed: 30 meters per minute

Total Motor Power: 1.5 kW

Overall Dimensions: 3500 × 1000 × 900 mm

Total Weight: 700 kg

Logs Debarking machines

Length of Log: 970–1270 mm

Diameter of Log: 600 mm

Debark Peeling Thickness: 2.0–6.0 mm

Debark Peeling Speed: 50 meters per minute

Total Motor Power: 27.5 kW

Overall Dimensions: 2980 × 2160 × 1320 mm

Total Weight: 3000 kg

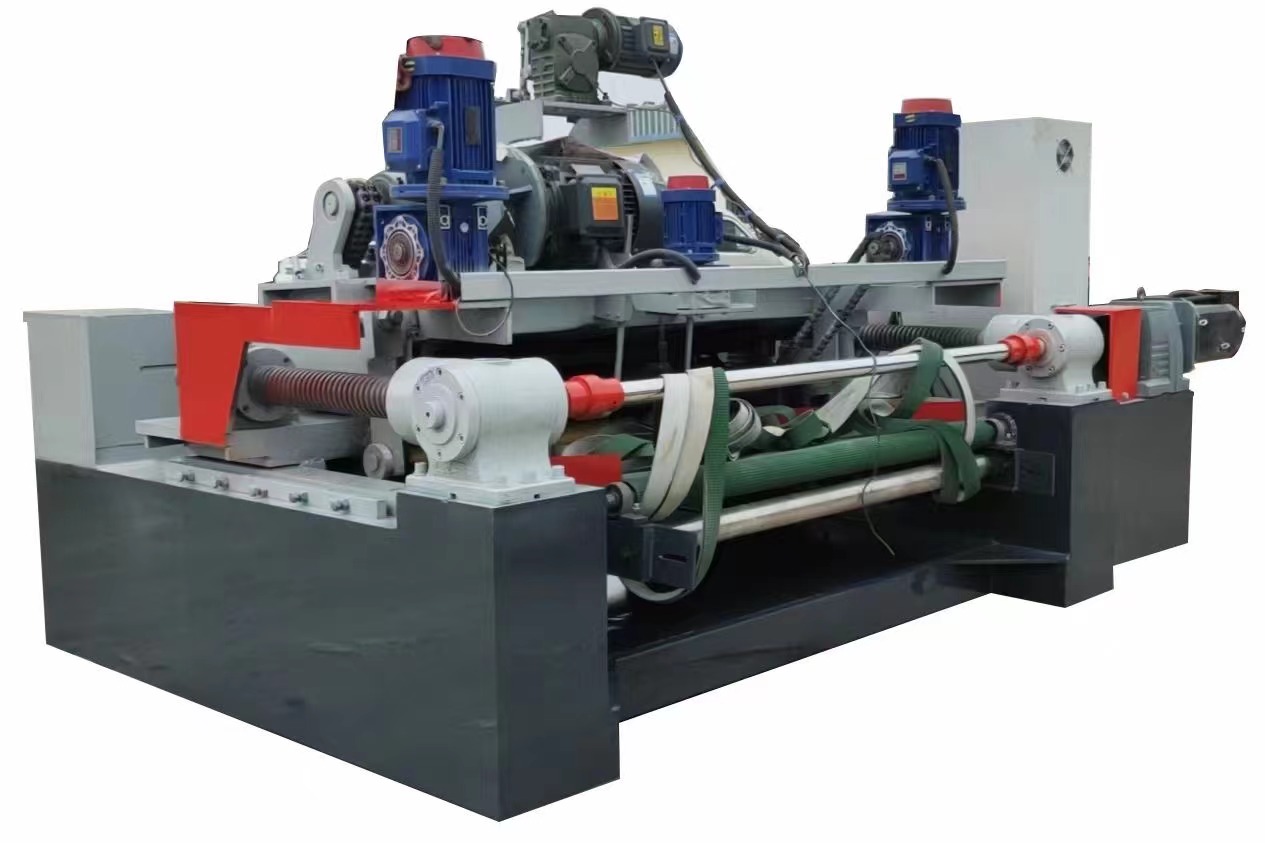

Veneer Peeling machines

High Speed Veneer Stacking Machine

Total weight: 1200 kg

The whole veneer production process is fully automated, which cuts down waiting times between each step. Unlike slowly manual work, the automatic line ensures steady and fast production, boosting overall veneer production output.

From loading logs, debarking to peeling veneer and stacking, every step is controlled by automated systems. This precise control keeps the veneer thickness precise and the size consistent, reducing defects and improving quality.

Traditional production needs at least 8 workers from log cutting, log moving, log debarking, veneer peeling, veneer sorting and collecting and stacking. With full automation, only 1 or 2 operators are needed, saving a lot on labor costs.

Automatic machines have multiple safety features to reduce mistakes caused by humans and keep the workplace safer.

By accurately controlling cutting settings, the machine reduces wood waste and makes better use of raw materials, which lowers production costs.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.