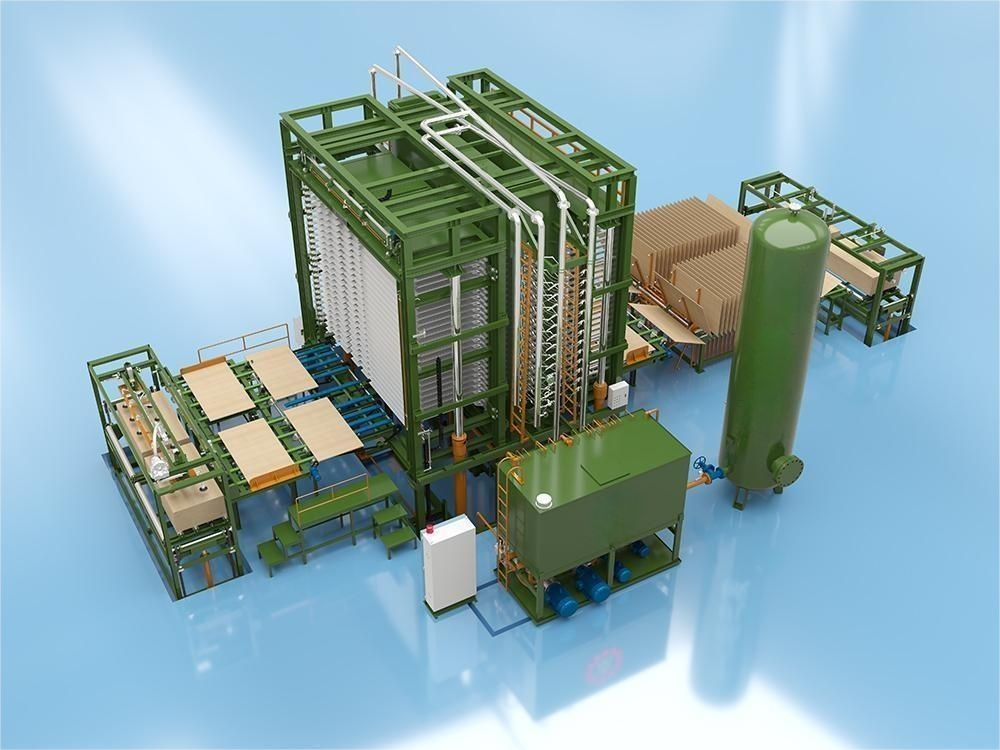

| Nominal Pressure | 10000KN |

| hot press platen size | 4200(L)*1370(W)*60mm(H) |

| Feeding mode | double input and double output |

| Plywood size(mm) | 12703000mm,12703650mm,12703950mm,12701830mm,970*1830mm |

| Max. opening space | 80mm |

| Number of layers | 25 layers |

| Main oil cylinder of press | Φ2602150mm8PCS |

| Working stroke(mm) | 2000mm |

| Working press(kg/cm2) | 17kg/cm2 |

| Closing speed(M/min) | 15M/min |

| Overall size(mm) | 5030mm(L)*1370mm(W)*7200mm(H) |

| Nitrogen tank size | 1440mm*6620mm(9CBM) 1PC |

| Weight of Nitrogen tank | 4900kgs |

| Hydraulic station size | 3200mm(L)*1500mm(W)*2800mm(H) |

| Tank Volume | 7CBM |

| Total weight of hydraulic station | 5800KGS |

| Low pressure pump motor | 22KW*2PCS |

| High pressure pump motor | 5.6KW*1PC |

| Elevator motor | 2.2KW*1PC |

| Total power | 51.8KW |

| Depth of foundation | 3000mm |

| Total weight | 120T |

| Hydraulic station | Fully sealed dust-free design |

| Total weight | 90T |

Benefits of Choosing the 25-Layer Full Automatic Hot Press

In short, a 25-layer full automatic hot press means higher output, lower costs, less space, better quality, and safer production.

What Factories Suitable for a 25-Layer Full Automatic Hot Press

FAQ for 25-Layer Full Automatic Hot Press

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.