Suitable Wood Types & Processing Parameters

Wood Types: Eucalyptus, Poplar, Pine, Hard Mixed Wood,birch,etc

Cutting Thickness: 0.5–4.0 mm

Cutting Speed: 60–100 m/min

Notes:

Adjustable speed ensures smooth peeling for different wood densities.

Ideal for producing uniform veneer thickness and high-quality surface finish

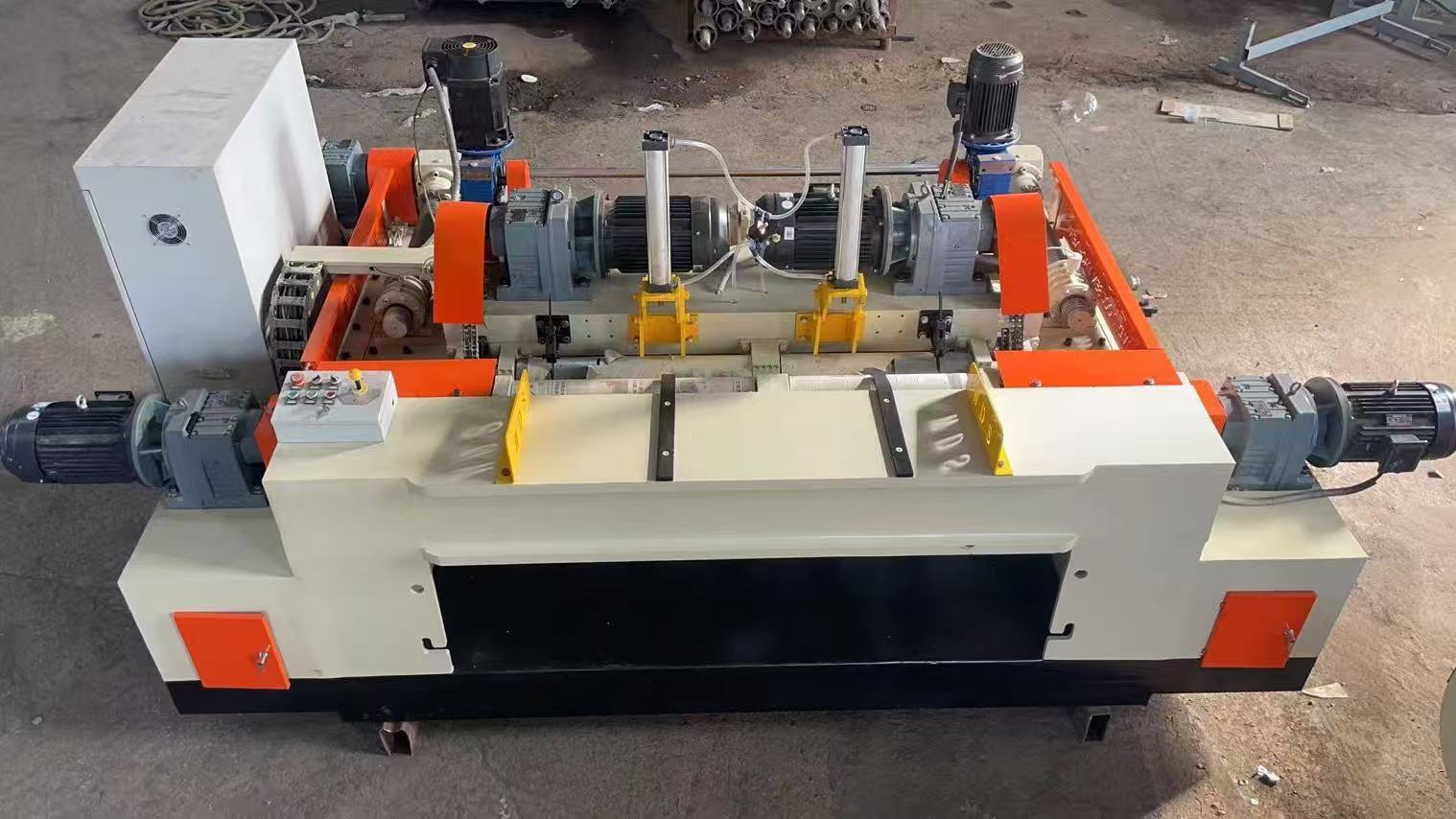

Double Roller (Ø125mm, Cross) – R87 Hard Gear Reducer, 7.5 kW ×2

Single Roller (Ø125mm) – R87 Hard Gear Reducer, 7.5 kW×2

Feed – R87 Hard Gear Reducer, 11 kW Servo Motor ×1

Cutter – RV90 Reducer, 2.2 kW Servo Motor ×1

Rubber Roller (Ø150mm) – RV90 Reducer, 2.2 kW Motor ×1

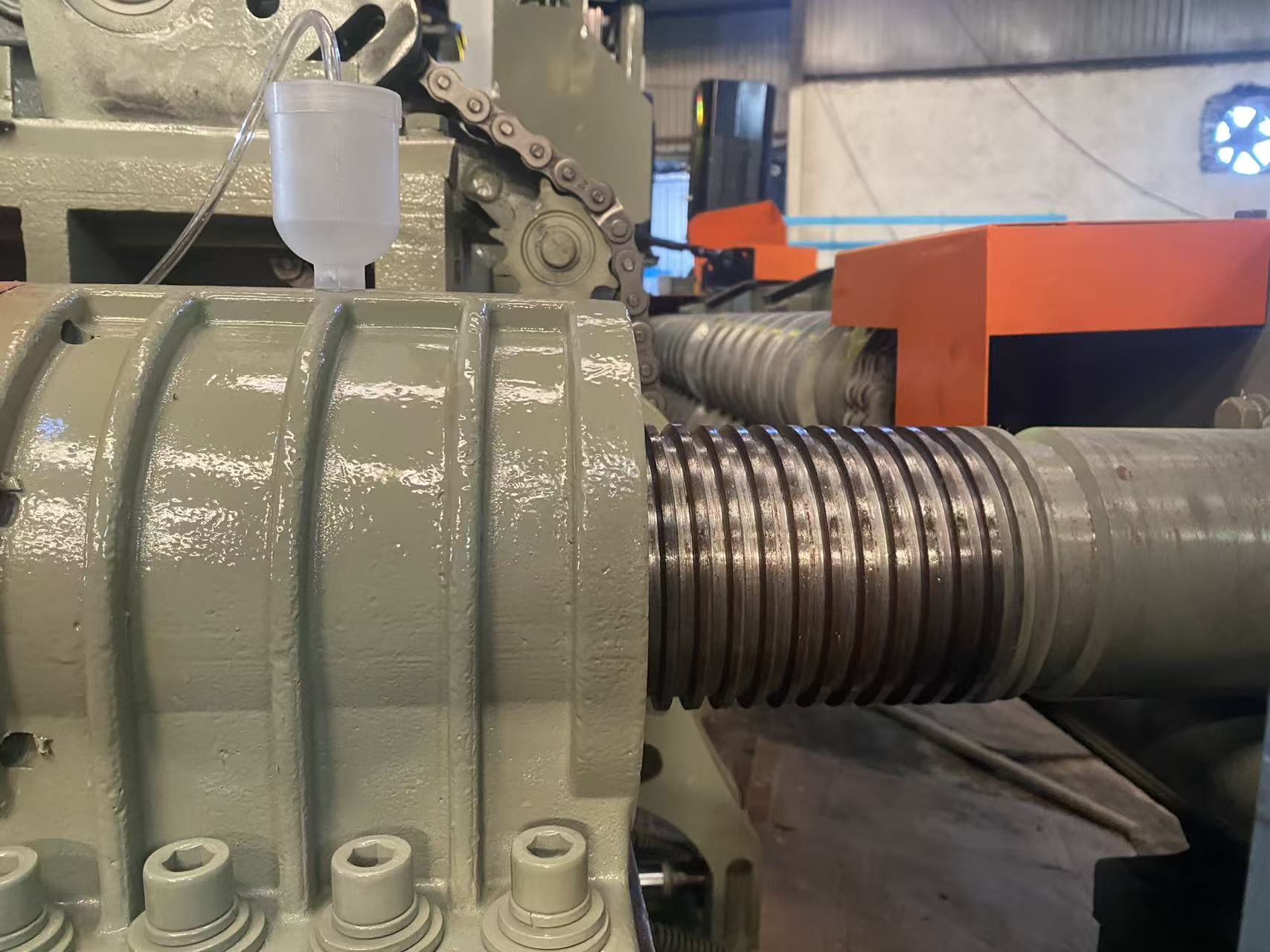

Guide – Oil-immersed Slide Bar, Screw Ø95mm ×1 set

Conveyor Belt – 5 m + 2 m

Cutting Knife Size – 1500 × 180 × 16 mm

Vertical Knife Size – 889 / 965.2 / 1270 mm

Cutting Thickness – 0.8–4.0 mm

Cutting Speed – 30–100 m/min

Overall Size – L 4700 × W 2100 × H 1700 mm

Maximum Processing Diameter – 550 mm

Minimum Remaining Diameter – 26 mm

Weight – 5.5 T

Double Seat Plate – 25#

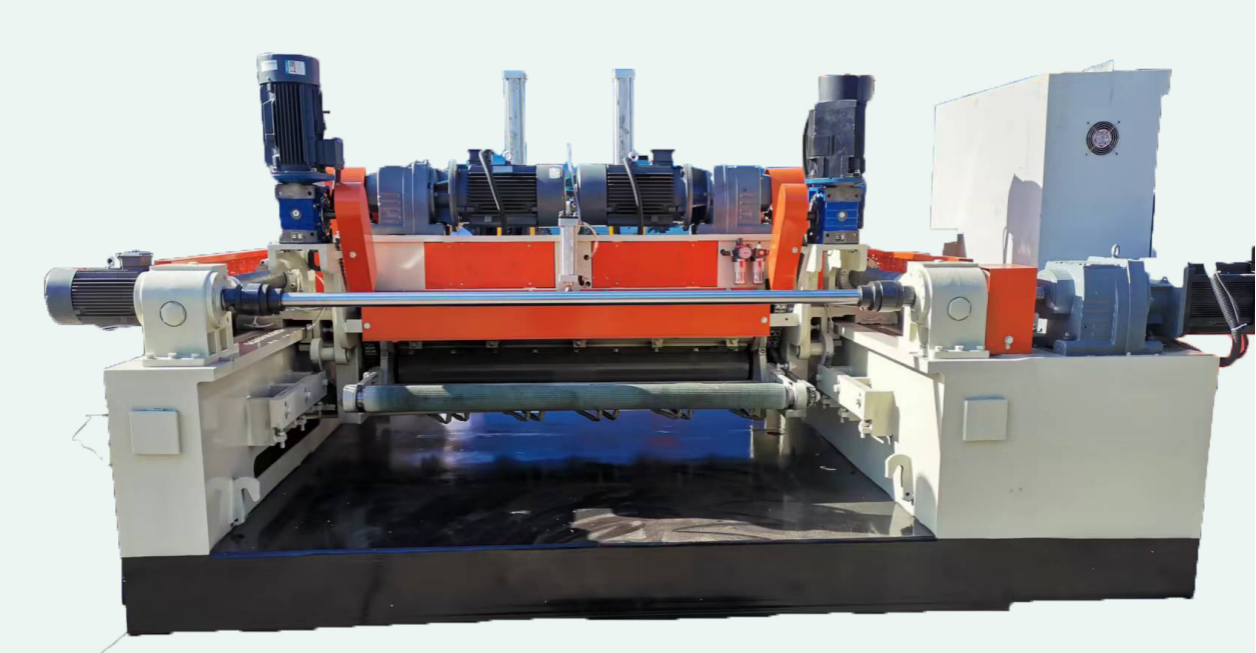

Precise & Smooth Cutting – Rollers and servo feed work together to keep veneer thickness even and the surface perfectly smooth.

Strong & Reliable – Durable gear reducers and powerful motors keep the machine running steadily, even under heavy load.

Flexible & Efficient – Cutting speed (30–100 m/min) and processing diameter up to 550 mm handle different wood sizes easily.

Built to Last – Heavy-duty gears, oil-guided slides, and quality steel parts reduce wear and need less maintenance.

Easy to Use & Space-Saving – Compact design with built-in conveyor makes operation simple and saves floor space.

Hardness: Medium to hard, depending on species

Fiber: Mostly straight; some species have higher moisture content

Moisture Content: Fresh logs 50–60%; dried wood around 10–12%

Motors & Gear Reducers

Main rollers: 7.5 kW motors ×2 with R87 hard gear reducers

Feed system: 11 kW servo motor

Cutter: 2.2 kW servo motor + RV90 reducer

✅ Comment: Power is more than enough for medium-hard wood like eucalyptus

Cutting Capacity

Thickness: 0.8–4.0 mm

Speed: 30–100 m/min (adjustable)

Max log diameter: 550 mm

✅ Comment: Most eucalyptus logs fall between 300–500 mm, fully compatible. Adjustable speed ensures smooth cutting for different wood densities

Cutter & Rollers

Double roller, single roller, and rubber roller combination stabilizes logs and prevents vibration

Cutting knife length 1500 mm handles full log width

✅ Comment: Ensures even veneer thickness and a clean, smooth surface

Tips:

For high-moisture logs, slightly dry or maintain consistent moisture to protect blades and improve cutting quality

Adjust cutting speed based on wood hardness to ensure the smoothest finish

Automatic Knife Tightening allows the veneer peeling lathe to lock the knife automatically by hydraulic or pneumatic force. It replaces manual tightening, ensuring uniform pressure, stable cutting, and smooth veneer surface. This function improves safety, saves time during knife changes, increases production efficiency, and reduces the risk of knife loosening during high-speed operation.

Why We Use Lead Screw in the Veneer Peeling Machine?

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.