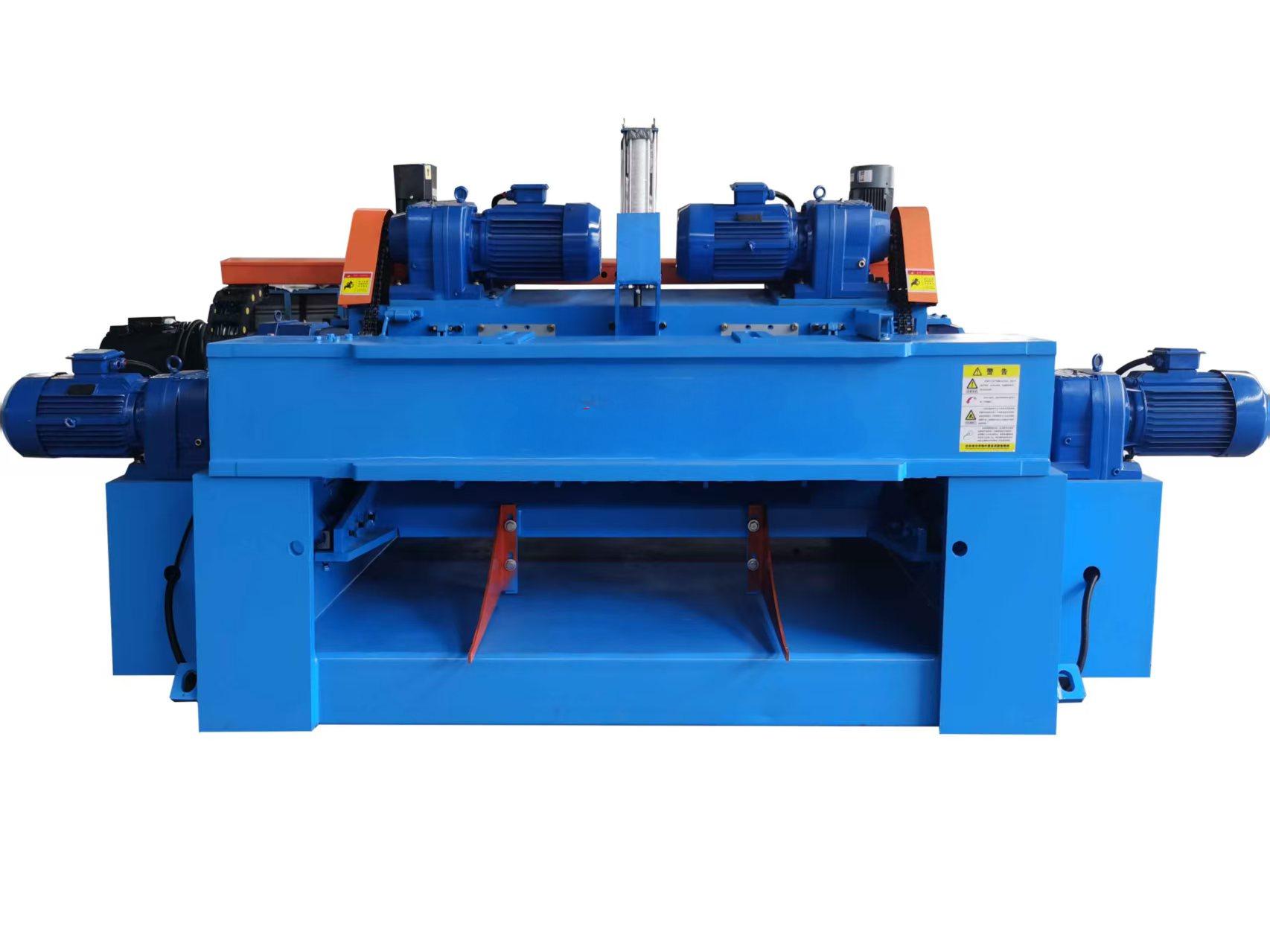

Max Opening: 500 mm

Minimum Log Core Diameter: 30 mm

Peeling Thickness Range: 0.8 – 4.0 mm

Machine Size (L × W × H): 4000 × 2300 × 1600 mm

Machine Weight: 6500 kg

Motor Power

Power of Double Roller: 7.5 kW × 2, AC Servo Induction Motor

Power of Single Roller: 7.5 kW × 2, AC Servo Induction Motor

Power of Screw Feed: 11 kW, AC Servo Induction Motor

Power of Rotary Clipper: 1.5 kW, AC Servo Induction Motor

Power of Rubber Roller: 1.5 kW, AC Induction Motor

Total Power: 44 kW

Length of the Roller: 1500 mm

Roller Reducer: Helical Gear Reducer × 4 (Model: R87, Hardened Gear Surface)

Screw Feed Reducer: Helical Gear Reducer × 1 (Model: R87, Hardened Gear Surface)

Clipper Reducer: Worm Gear Reducer × 1 (Model: RV130)

Rubber Roller Reducer: Worm Gear Reducer × 1 (Model: RV130)

Veneer Output Speed: from 30 to 80 m/min

Blade Size: 1500 × 180 × 16 mm

Screw Diameter: 90 mm

Clipper Width: ≥ 400 mm

Control System:

Peeling Speed Adjust System

Closed-loop Servo Control

PLC + Touch Screen

Why Choose the Wood Veneer Peeling Machine from China?

More competitive pricing: Thanks to China’s strong industrial clusters, the cost of spare parts is low. Combined with lower labor costs and large-scale production, Chinese veneer peeling machines are much more affordable—especially suitable for developing countries and small-to-medium wood factories.

Most manufacturers have over 20 years of experience, with well-optimized machine structure and stable performance.

Modern machines use servo systems, PLC + touch screen control, and offer higher precision and automation.

New-generation models support high-precision peeling, automatic centering, automatic knife gap adjustment, and automatic knife tightening.

Fully automatic feeding, peeling, and stacking systems are widely available.

Can be integrated with dryer lines, glue spreaders, and hot press machines for full-line automation.

Some factories even provide IoT smart monitoring systems for remote operation and troubleshooting.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.

*We respect your confidentiality and all information are protected.

I’m Leo, the head of sales team at E-abel. Me and my team would be happy to meet you and learn all about your business, requirements and expectations.

*We respect your confidentiality and all information are protected.

lunamachines@outlook.com

Yitang Industrial Zone, Lanshan District, Linyi City, Shandong Province, China

*We respect your confidentiality and all information are protected.

Hi, I’m Luna, Head of Sales at Guoyu. My team and I would be delighted to learn more about your specific requirements and support your plywood production.