In the rapidly evolving plywood manufacturing sector, selecting the right production line equipment is critical to achieving unmatched efficiency, long-term durability, and competitive advantage. As global demand for high-quality engineered wood continues to rise, Chinese manufacturers have solidified their position as leaders in innovative, cost-effective machinery solutions. This 2026 review highlights the top 10 plywood production line machine suppliers leveraging advanced technology and scalable engineering to deliver robust, high-performance systems trusted by wood product manufacturers worldwide.

Top 10 Plywood Production Line Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 Plywood Making Machine, Plywood Production Line, Veneer …

Official Website: ply-machine.com

We supply plywood machinery manufacturing and scheming, layout, automation desgin,processing technology, glue formula,etc,which including veneer peeling ……

#2 Raute

Founded: 1908

Official Website: raute.com

Since 1908, companies have relied on Raute to deliver transformational machinery and technological services….

#3 Swanson Group Forest Products

Official Website: swansongroup.biz

Renowned for their excellence, our broad selection of plywood products are highly regarded by dealers and builders across the nation, and internationally….

#4 The Plywood Manufacturing Process At ADX

Official Website: adxplywood.com

The plywood manufacturing process at ADX meets international safety standards and is trusted by many major partners around the world….

#5 Plywood Production Proces

Official Website: pagedplywood.com

The hydrothermal processing is carried out in soaking pools filled with water at a temperature of 40–60°C depending on the wood species….

#6 Plywood

Official Website: biele.com

We design and manufacture highly automated solutions for all plywood production processes. Our in-depth knowledge of plywood panels pressing and handling….

#7 Coquille Plywood

Founded: 1958

Official Website: roseburg.com

Since 1958, Roseburg has been manufacturing a wide range of softwood plywood products for your building construction applications….

#8 Buy Plywood Wholesale Direct from Manufacturer

Official Website: plyterra.com

Plyterra is a trusted plywood manufacturer with over 20 years of expertise. Offering a wide range of plywood grades and types for wholesale buyers….

#9 Columbia Forest Products

Official Website: columbiaforestproducts.com

Discover Columbia Forest Products, North America’s largest manufacturer of sustainable, decorative hardwood plywood and veneers for residential and commercial ……

#10 Plywood Company Plywood Suppliers

Official Website: garnica.one

Garnica is a plywood supplier, a world leader in the production and innovation of popular board from sustainable European plantations. Discover Garnica….

Professional Buying Guide: Plywood Production Line Machinery

2026 Global Market Trends in Plywood Production Line: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

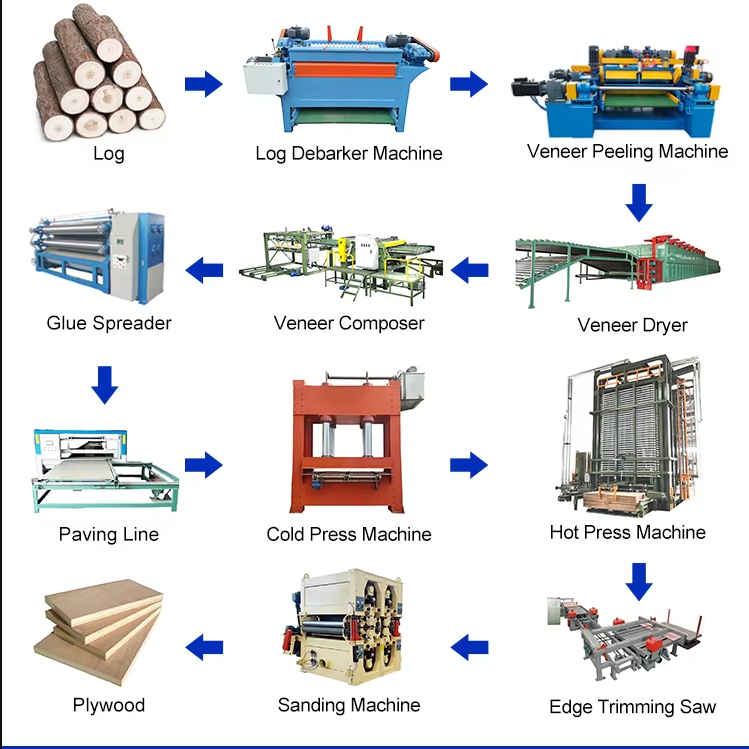

Automation Integration Accelerates in Plywood Manufacturing

By 2026, automation is set to become a cornerstone of the global plywood production line industry. Manufacturers are increasingly adopting advanced automation technologies such as robotic arms for veneer handling, automated glue spreaders, and AI-driven quality inspection systems. These innovations reduce human error, improve consistency, and streamline production workflows. The integration of Industrial Internet of Things (IIoT) sensors enables real-time monitoring and predictive maintenance, minimizing downtime. Leading markets in Europe and North America are at the forefront, while emerging economies in Southeast Asia and India are rapidly adopting automated systems to remain competitive. Automated sorting and stacking systems are particularly transforming post-press operations, enhancing throughput and reducing material waste.

Energy Efficiency Becomes a Key Competitive Advantage

Energy efficiency is emerging as a critical factor in the sustainability and profitability of plywood production lines. With rising energy costs and tightening environmental regulations, manufacturers are investing in energy-efficient drying systems, such as low-emission thermal oil dryers and heat recovery units. Solar-powered drying kilns and biomass-based energy solutions are gaining traction, especially in regions with abundant renewable resources. The shift toward electric hot presses powered by renewable energy sources is also expected to grow. By 2026, energy-efficient production lines could reduce operational costs by up to 25%, making them a strategic priority for both new installations and plant retrofits. Certifications like ISO 50001 are becoming standard, further driving energy-conscious production practices.

High-Speed Production Lines Enhance Output and Scalability

The demand for higher output and faster turnaround is pushing the adoption of high-speed plywood production lines. Innovations in press technology—such as continuous press lines (e.g., Carbondizer and ContiRoll systems)—enable production speeds of over 100 meters per minute, significantly surpassing traditional batch presses. These systems allow for seamless, uninterrupted manufacturing of multi-layered panels with consistent quality. High-speed lines are particularly beneficial for large-scale producers serving construction and furniture industries. By 2026, high-speed production is expected to dominate new capacity expansions, especially in China, Russia, and Vietnam. Coupled with digital process control systems, these lines can dynamically adjust parameters to optimize yield and reduce material waste.

Labor Cost Reduction Drives Technological Adoption

Labor cost reduction remains a primary driver behind the modernization of plywood production lines. As wages rise globally—especially in major manufacturing hubs like China and Eastern Europe—producers are turning to technology to maintain margins. Fully automated lines now require 40–60% fewer operators compared to conventional setups. Machine vision systems and automated defect detection reduce reliance on manual inspection, while centralized control rooms enable remote monitoring and operation. In addition, workforce training is shifting toward technical maintenance and system supervision rather than manual labor. This trend not only lowers labor expenses but also mitigates risks associated with labor shortages and turnover. By 2026, labor cost savings from automation are projected to account for a significant portion of ROI for new production line investments.

In conclusion, the 2026 global plywood production landscape will be defined by smarter, faster, and more sustainable manufacturing processes. Automation, energy efficiency, high-speed capabilities, and labor optimization are converging to reshape the industry, favoring producers who embrace innovation and digital transformation.

Key Check Points for Evaluating a High-Quality Plywood Production Line

When assessing the quality and reliability of a plywood production line, several critical components must be carefully evaluated. The following check points focus on long-term performance, operational efficiency, and maintenance support.

Steel Structure Durability

The steel frame forms the backbone of the production line and directly impacts stability, alignment, and longevity. A high-quality line should feature heavy-duty, corrosion-resistant steel (e.g., Q345 or equivalent), precision-welded to minimize deformation. Look for galvanized or powder-coated finishes to resist moisture and industrial wear. Ensure structural joints and supports are reinforced for continuous operation under high pressure and temperature.

Motor Brand (e.g., Siemens/Mitsubishi)

The motors drive critical functions such as hot presses, conveyors, and veneer stackers. Reputable brands like Siemens, Mitsubishi, ABB, or SEW are indicators of reliability, energy efficiency, and durability. Verify the motor specifications match the load requirements and operating conditions. Motors from top-tier brands typically offer better thermal protection, longer service life, and consistent torque output, reducing downtime.

PLC Control System

A robust PLC (Programmable Logic Controller) system ensures precise automation, process monitoring, and fault diagnostics. Leading systems from Siemens, Allen-Bradley (Rockwell), or Mitsubishi provide user-friendly HMI (Human-Machine Interface), real-time data logging, and remote troubleshooting capabilities. Confirm that the PLC is customized for plywood manufacturing processes, supports seamless integration with sensors and actuators, and allows for easy parameter adjustments.

Spare Parts Availability

Timely access to spare parts is essential for minimizing production interruptions. Evaluate the supplier’s global or regional service network and inventory support. High-quality manufacturers often provide comprehensive spare parts lists, maintain local warehouses, and offer long-term parts supply commitments. Check if common wear components (e.g., heating plates, belts, rollers, sensors) are readily available and compatible with international standards.

Guide for Importing Plywood Production Line from China

Voltage Requirements (380V/220V)

When importing a plywood production line from China, it is essential to verify the electrical specifications of the machinery. Most industrial equipment in China operates on a standard three-phase voltage of 380V at 50Hz. However, some smaller components or auxiliary machines may require 220V single-phase power. Before placing your order, confirm the exact voltage and frequency requirements with the supplier and ensure they match your facility’s electrical infrastructure. If your local power supply differs (e.g., 480V/60Hz in North America), request the manufacturer to customize the electrical system or supply a compatible transformer. Failure to align voltage specifications can lead to equipment damage or safety hazards.

Installation Support

Reputable Chinese manufacturers typically offer installation and commissioning support as part of the purchase agreement. This may include sending technical engineers to your site to oversee the setup, calibrate machinery, and train your operators. Confirm whether this service is included in the contract or offered at an additional cost. Some suppliers provide remote support via video calls or manuals if on-site assistance is not feasible. Ensure the supplier delivers comprehensive installation documentation, including equipment layout diagrams, piping schematics, and safety guidelines. Clarify response times for technical queries and availability of multilingual support to avoid communication barriers.

Warranty Terms

Warranty coverage is a critical factor when importing heavy machinery. Most Chinese suppliers offer a standard 12-month warranty on the entire plywood production line, covering defects in materials and workmanship. Key components such as hot presses, veneer peelers, and gluing machines may have specific warranty conditions. Review the terms carefully to understand what is included—typically, parts replacement and technical support—but note that labor costs for on-site repairs may not be covered, especially outside China. Warranties often exclude damage from improper installation, misuse, or lack of maintenance. Ensure warranty claims can be processed efficiently and confirm whether spare parts will be supplied promptly during the warranty period.

Spare Blade and Part Kits

To minimize downtime, always request a comprehensive spare parts kit when purchasing a plywood production line. This should include high-wear items such as cutting blades, saw teeth, press platens, bearings, belts, and sealing components. Ask the supplier to provide a detailed spare parts list with recommended quantities based on expected usage. Some manufacturers offer discounted starter kits or maintenance packages. Verify the availability of spare parts beyond the initial supply and inquire about lead times for reordering. Ensure the supplier maintains an inventory of critical components and can ship replacements quickly. Keeping an adequate stock of spares on-site is crucial for continuous operation and long-term reliability.

In conclusion, sourcing a plywood production line from China can offer significant cost advantages and access to advanced manufacturing technologies. However, to ensure long-term operational efficiency, product quality, and compliance with international standards, it is essential to conduct thorough due diligence. A critical step in this process is verifying that the machinery carries valid CE certification, which confirms adherence to European safety, health, and environmental protection standards. Additionally, arranging for pre-shipment inspection and functional testing of the production line is strongly recommended. This allows buyers to verify machine performance, identify potential defects, and ensure that all components meet the agreed specifications before goods are dispatched. By prioritizing certification verification and on-site testing, buyers can mitigate risks, enhance equipment reliability, and secure a successful investment in their plywood manufacturing operations.