In 2026, the global demand for high-performance plywood hot press machines continues to rise, driven by evolving production standards and the need for greater efficiency and durability. As a critical component in engineered wood manufacturing, these machines must deliver consistent heat and pressure over extended cycles—making the choice of manufacturer pivotal. China, recognized for its advanced industrial capabilities and competitive manufacturing ecosystem, has emerged as a leading hub for robust, precision-engineered solutions. This review highlights the top seven plywood hot press machine manufacturers excelling in reliability, innovation, and performance, offering B2B buyers insight into trusted partners for scalable, long-term production success.

Top 7 Plywood Hot Press Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Plywood Hot Press Machine Manufacturers Suppliers Factory

Official Website: focus-mach.com

We’re well-known as one of the leading plywood hot press machine manufacturers and suppliers in China. Please rest assured to buy high quality equipment for ……

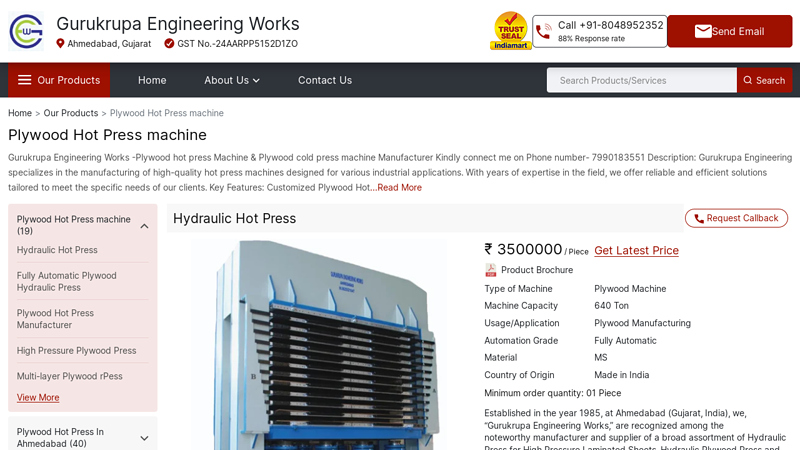

#2 Plywood Hot Press machine

Official Website: gurukrupahydraulic.com

We are the Manufacturer of Hydraulic Hot Press For Laminate & Plywood. We are also manufacturer of Core Dry Press Machines , Hydraulic Cold Press , Hydraulic ……

#3 Biesse

Official Website: biesse.com

Biesse is an international company producing lines, machines and components for the industrial processing of wood, glass, stone, polymers and composites….

#4 PLYWOOD PRESS

Official Website: shivmachineries.com

Power: 25 HP · Usage/Application: Plywood Manufacturing · Model Number/Name: SI-640 · Capacity: 640 Ton · Automatic Grade: Fully Automatic · Brand: Shiv Industries….

#5 Automatic Plywood Hot Press Machine for Wood

Official Website: 3mjx.com

Made of fabricated steel, the hot press plywood press machine can be installed anywhere on the floor of the factory without occupying too much space….

#6 Hot Press Machine For Plywood Latest Price …

Official Website: dir.indiamart.com

30 HP 1250 Ton High Densified Ply Hydraulic Hot Press Machine, Motor Power: 2 HP · 22 kw HVP Type 3 Format 4 Plywood Hot Press Machine, Machine Capacity: 120 ……

#7 Automatic Woodworking Plywood Hot Press Machine

Official Website: plywoodmachineline.com

Plywood hot press machine with automatic loader & unloader, for plywood manufacturing. Hot press machine can be different layers, pressure, and its hot plate ……

Professional Buying Guide: Plywood Hot Press Machinery

2026 Global Market Trends for Plywood Hot Press: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

Automation: Driving Precision and Operational Consistency

In 2026, automation is a defining factor in the evolution of plywood hot press systems. Manufacturers are increasingly integrating advanced automation technologies—such as PLC (Programmable Logic Controllers), AI-driven process monitoring, and robotic material handling—into hot press operations. These systems enable real-time adjustments of pressure, temperature, and cycle time, ensuring consistent panel quality and reducing human error.

Automated loading/unloading systems and conveyor integration streamline workflow from veneer stacking to pressing and post-press handling. Companies in Europe and North America are leading in adopting Industry 4.0 concepts, including predictive maintenance and digital twins, to optimize uptime and reduce equipment failure. In emerging markets like Southeast Asia and India, rising labor costs and the need for quality standardization are accelerating automation adoption, making smart hot presses a competitive necessity by 2026.

Energy Efficiency: Meeting Sustainability and Regulatory Demands

Energy efficiency has become a critical driver in the design and operation of modern plywood hot presses. With increasing global emphasis on carbon neutrality and stricter environmental regulations, manufacturers are investing in energy-optimized systems. By 2026, new hot presses are expected to feature enhanced thermal insulation, heat recovery systems, and hybrid heating technologies—such as combining steam and electric heating—to reduce energy consumption by up to 30% compared to older models.

The shift toward biomass and electric heating systems, especially in EU and Scandinavian countries, aligns with regional green energy policies. Additionally, variable frequency drives (VFDs) for hydraulic pumps and optimized press platen heating zones are standard in next-gen equipment. These improvements not only lower operational costs but also support manufacturers in achieving environmental certifications (e.g., FSC, PEFC, and LEED compliance), enhancing market access and brand reputation.

High-Speed Production: Enabling Scalability and Responsiveness

The demand for faster turnaround and just-in-time delivery is pushing the plywood industry toward high-speed hot press systems. In 2026, advanced presses are capable of cycle times under 60 seconds per batch, a significant improvement from traditional 90–120 second cycles. This leap is achieved through rapid heating/cooling systems, precision pressure control, and synchronized multi-opening press designs.

High-speed production lines are particularly prevalent in large-scale operations in China, Russia, and Eastern Europe, where economies of scale favor throughput maximization. Innovations such as continuous press technology (derived from MDF production) are being adapted for plywood, enabling near-continuous pressing with minimal downtime. These systems improve line efficiency and allow manufacturers to respond swiftly to fluctuating market demands, especially in construction and furniture sectors.

Labor Cost Reduction: Enhancing Profitability Through Technology Integration

Labor cost reduction remains a key motivator for investment in modern plywood hot press systems. By 2026, fully automated lines require 40–60% fewer operators compared to conventional setups. Robotics for veneer sorting, glue application, and stack assembly significantly reduce manual labor, while centralized control rooms allow a single operator to manage multiple press lines.

In regions facing labor shortages—such as Germany, Japan, and South Korea—this trend is especially pronounced. Even in lower-wage countries, rising labor expectations and urban migration are making automation a strategic imperative. Moreover, reduced human involvement lowers injury risks and training costs, contributing to safer and more sustainable operations. As a result, ROI on automated hot press systems is improving, making them accessible to mid-sized producers by 2026.

Conclusion

By 2026, the global plywood hot press market will be shaped by the convergence of automation, energy efficiency, high-speed production, and labor cost reduction. These trends are not only improving operational performance but also aligning the industry with sustainability goals and digital transformation. Manufacturers who embrace these innovations will gain a competitive edge in quality, cost-efficiency, and environmental compliance, positioning themselves for long-term success in a rapidly evolving market landscape.

Key Evaluation Criteria for a High-Quality Plywood Hot Press

When selecting a plywood hot press, assessing the following critical components ensures long-term performance, reliability, and minimal downtime:

Steel Structure Durability

The steel frame and platen construction are fundamental to the press’s longevity and consistent pressing results. Look for thick, high-tensile steel (e.g., Q345B or equivalent) used in the main frame and heated platens. The structure should be stress-relieved to prevent warping and maintain parallelism under high pressure and temperature. Precision-machined platens with uniform thickness ensure even heat distribution and consistent glue curing across the entire panel surface.

Motor Brand and Drive System

High-performance motors are essential for reliable hydraulic and mechanical operations. Reputable brands such as Siemens, Mitsubishi, or ABB offer superior efficiency, durability, and energy savings. Verify that both the main hydraulic pump motor and circulation pumps are from trusted manufacturers. A premium motor reduces maintenance frequency and enhances overall system responsiveness and control.

PLC Control System

A robust PLC (Programmable Logic Controller) system ensures precise temperature, pressure, and timing control during the pressing cycle. Leading systems use Siemens, Mitsubishi, or Omron PLCs, which offer stable performance, user-friendly HMI (Human-Machine Interface), and programmable recipes for different plywood types. Look for systems with data logging, fault diagnostics, and remote monitoring capabilities to improve operational efficiency and troubleshooting.

Spare Parts Availability

Ensure that critical spare parts—such as seals, heating elements, hydraulic valves, sensors, and PLC modules—are readily available and supported by the manufacturer or local distributors. Presses built with standardized components from global brands (e.g., Parker hydraulics, Siemens electricals) simplify maintenance and reduce downtime. Confirm the supplier offers a comprehensive spare parts list and technical support to avoid prolonged production halts.

Guide for Importing Plywood Hot Press Machines from China

Voltage Requirements (380V/220V)

When importing a plywood hot press from China, it’s crucial to confirm the machine’s electrical specifications match your local power supply. Most industrial hot presses manufactured in China operate on 380V, 3-phase, 50Hz, which is standard for Chinese factories. However, some smaller or customized models may be built for 220V, single-phase power, typically used in regions with different electrical standards.

- Verify Voltage Compatibility: Ensure your facility can support 380V 3-phase power. If your local supply is 220V or 480V, discuss with the supplier the possibility of customizing the electrical system or using a transformer.

- Request Detailed Electrical Drawings: Ask the manufacturer for circuit diagrams, motor specifications, and control panel details to confirm compatibility.

- Compliance and Certification: Confirm the machine meets international electrical safety standards (e.g., CE, ISO) and can be adapted for use in your country.

Installation Support

Proper installation is vital for the safe and efficient operation of a plywood hot press. Chinese suppliers vary in the level of support they offer:

- On-Site Installation Assistance: Many reputable manufacturers offer optional on-site installation support, where a technician is sent to your facility to oversee setup, calibration, and initial operation. This service may incur additional costs (travel, labor, duration).

- Remote Support: If on-site service is not feasible, ensure the supplier provides comprehensive installation manuals, wiring diagrams, and video guidance. Real-time support via phone or video call should also be available during setup.

- Pre-Installation Requirements: The supplier should clearly outline foundation specifications, space requirements, utility connections (power, compressed air, steam/hydraulic lines), and safety clearances.

Warranty Terms

Understanding the warranty coverage is essential to protect your investment:

- Standard Warranty Period: Most Chinese manufacturers offer a 12-month warranty from the date of shipment, covering defects in materials and workmanship.

- Coverage Details: Warranty typically includes major components such as the hydraulic system, heating plates, control system, and frame. Consumables like heating elements or seals may have shorter coverage (e.g., 6 months).

- Exclusions: Damage due to improper installation, misuse, lack of maintenance, or unauthorized modifications is generally not covered.

- Service Response: Clarify how warranty claims are handled—whether parts are shipped free of charge, if technical support is included, and if on-site repairs are provided (and at what cost).

- Extended Warranty Options: Some suppliers offer extended warranties for an additional fee, which may be worthwhile for critical production environments.

Spare Blade and Part Kits

Having spare parts on hand minimizes downtime and ensures continuous operation:

- Recommended Spare Parts Kit: Request a comprehensive spare parts package from the manufacturer, which should include:

- Heating plate gaskets or seals

- Hydraulic seals and hoses

- Pressure sensors and thermocouples

- Control system fuses and relays

- Spare blades (if applicable for trimming or cutting attachments)

- Fasteners, bolts, and alignment pins

- Customization Based on Usage: High-production facilities may want to stock additional heating elements, pump components, or PLC modules.

- Availability and Lead Time: Confirm how quickly spare parts can be supplied post-purchase. Reputable suppliers maintain inventory and offer fast shipping (often via DHL or FedEx).

- Part Number List: Obtain a detailed parts manual with part numbers and diagrams to simplify future ordering.

By carefully addressing voltage requirements, securing installation support, understanding warranty terms, and stocking essential spare parts, you can ensure a smooth import process and reliable operation of your plywood hot press from China.

In conclusion, sourcing a plywood hot press machine from China can offer significant cost advantages and access to advanced manufacturing technology. However, to ensure a successful and reliable procurement process, due diligence is essential. Buyers must prioritize verifying the CE certification of the machine, as it confirms compliance with European safety, health, and environmental protection standards—serving as a strong indicator of quality and reliability. Additionally, arranging for pre-shipment testing, either personally or through a trusted third party, is crucial to verify the machine’s operational performance, structural integrity, and adherence to technical specifications. By confirming CE certification and conducting thorough on-site testing before shipment, buyers can minimize risks, avoid costly delays or defects, and ensure the acquired equipment delivers long-term efficiency and value to their production operations.