In the evolving landscape of woodworking machinery, wood veneer in machines have become essential for achieving precision, quality, and production efficiency. As demand for high-performance equipment rises, manufacturers worldwide look to China—a powerhouse in industrial innovation and manufacturing excellence—for reliable, durable, and cost-effective solutions. This 2026 review highlights the top seven wood veneer in machine manufacturers leveraging cutting-edge engineering and robust build standards to deliver unmatched efficiency and long-term durability. Discover the leaders shaping the future of automated veneer insertion with scalable, high-output systems built for modern production environments.

Top 7 Wood Veneer In Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Plywood Machine Manufacturers, Suppliers and Factory

Official Website: hanvymachinery.com

Weihai Hanvy Plywood Machinery Manufacturing Co., Ltd. Head Office: No.20 Taishun Road, Weihai, Shandong, China 264211…

#2 Wood veneer machine Manufacturer & Supplier in China

Official Website: ply-machine.com

Why choose Sinoeuro Machinery Wood veneer machine? · Long-history Factory with Mature Technology · Experienced After-Sales Service & Timely Free On-line Service….

#3 Veneer machine Manufacturers & Suppliers

Official Website: unit-asia.com

Find reliable Veneer machine manufacturer, exporter, and factory in China. High-quality veneer machines available for purchase….

#4 Strong Wood Veneer Machine Manufacturer in China

Official Website: plywoodmachineline.com

Professional manufacturer produce the full sets of veneer machine and plywood machine in Linyi City, Shandong Province, China. Including Wood debarker, veneer ……

#5 Wood Veneer Crushing Machine

Official Website: logpeeling.com

YIHONG is one of the most professional wood veneer crushing machine manufacturers and suppliers in China. Please feel free to buy used wood veneer crushing ……

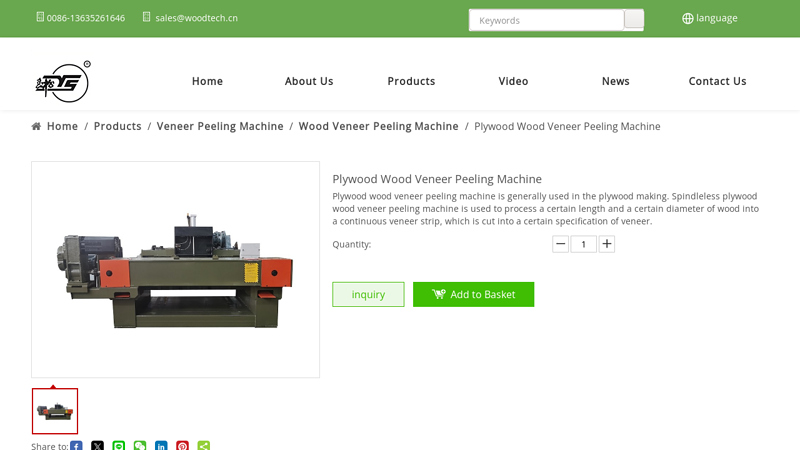

#6 Plywood Wood Veneer Peeling Machine from China manufacturer

Official Website: 3mjx.com

Spindleless plywood wood veneer peeling machine is used to process a certain length and a certain diameter of wood into a continuous veneer strip….

#7 Raute

Founded: 1908

Official Website: raute.com

Since 1908, companies have relied on Raute to deliver transformational machinery and technological services….

Professional Buying Guide: Wood Veneer In Machinery

2026 Global Market Trends for Wood Veneer: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

Automation in Wood Veneer Manufacturing

By 2026, automation is expected to be a cornerstone of innovation in the global wood veneer industry. Manufacturers are increasingly integrating advanced robotics, artificial intelligence (AI), and machine vision systems to streamline processes such as veneer slicing, grading, splicing, and stacking. Automated systems enhance precision in veneer thickness and grain alignment, reducing material waste and improving product consistency.

Smart factories equipped with Industrial Internet of Things (IIoT) technologies enable real-time monitoring of production lines, predictive maintenance, and adaptive control. This shift not only minimizes downtime but also allows rapid reconfiguration for custom veneer orders. Leading producers in Europe and North America are already deploying fully automated veneer lines, setting benchmarks for emerging markets in Asia and South America. By 2026, automation adoption is projected to grow by over 15% annually, driven by demand for high-quality, defect-free veneers in luxury furniture and architectural applications.

Energy Efficiency and Sustainable Production

Energy efficiency has become a strategic imperative in the wood veneer sector, with 2026 marking a pivotal point in the transition to low-carbon manufacturing. Veneer production—especially in the log steaming, slicing, and drying stages—is energy-intensive. To meet tightening environmental regulations and consumer sustainability expectations, manufacturers are investing in energy recovery systems, heat exchangers, and biomass-powered drying kilns.

Modern veneer dryers using variable frequency drives (VFDs) and closed-loop moisture control reduce energy consumption by up to 30%. Additionally, solar-assisted heating and waste-wood recycling are gaining traction, particularly in Scandinavia and Germany. Certifications such as FSC and EPD (Environmental Product Declaration) are now prerequisites for entry into premium markets, pushing companies to adopt energy-efficient practices. By 2026, over 60% of medium-to-large veneer producers are expected to have implemented comprehensive energy management systems (EnMS) aligned with ISO 50001 standards.

High-Speed Production Technologies

The demand for faster turnaround times and increased output is driving the adoption of high-speed production technologies in wood veneer manufacturing. Innovations such as high-frequency rotary cutters, continuous splicers, and automated lay-up systems are enabling throughput speeds exceeding 100 meters per minute—nearly double that of conventional lines from a decade ago.

Laser-guided slicing ensures micron-level accuracy, minimizing kerf loss and enabling thinner veneer production (down to 0.2 mm) without compromising strength. These technologies are particularly beneficial for engineered wood products like plywood and LVL (Laminated Veneer Lumber), where uniformity and scale are critical. High-speed lines also support just-in-time delivery models, reducing inventory costs for downstream users. With global construction and furniture markets rebounding post-2024, high-speed production capacity will be a decisive competitive advantage by 2026.

Labor Cost Reduction through Technological Integration

Labor costs remain a significant component of veneer production, especially in regions with rising wages and labor shortages. The 2026 outlook shows a clear trend toward labor cost reduction via end-to-end technological integration. Automated grading systems using AI-powered optical scanners can classify veneer quality at speeds unattainable by human inspectors—up to 95% accuracy with minimal supervision.

Robotic arms handle fragile veneer sheets during transfer and packaging, reducing breakage and reliance on manual labor. In countries like China and Vietnam, where labor costs have increased by 6–8% annually over the past five years, manufacturers are accelerating automation to maintain export competitiveness. Remote monitoring and centralized control systems further reduce the need for on-site technical staff. By 2026, automated facilities are expected to cut direct labor costs by 40–50% compared to traditional mills, reshaping the global cost structure of veneer production.

Conclusion

The 2026 global wood veneer market will be defined by a convergence of automation, energy efficiency, high-speed production, and labor cost optimization. These trends are not isolated but interdependent, with smart manufacturing ecosystems delivering both economic and environmental benefits. Companies that proactively invest in integrated digital and sustainable technologies will lead the market, while laggards risk obsolescence. As consumer and regulatory pressures intensify, technological advancement will be the primary driver of growth and resilience in the wood veneer industry.

How to Evaluate a High-Quality Wood Veneer Machine

When assessing the quality and reliability of a wood veneer machine—particularly for industrial applications—it’s essential to focus on key engineering and operational components. Below are critical check points to consider:

Steel Structure Durability

The machine’s steel structure forms the backbone of its performance and longevity. A high-quality veneer machine should feature a robust, precision-welded steel frame designed to minimize vibration and maintain alignment under continuous operation. Look for:

- Heavy-duty, thick-gauge steel construction

- Reinforced stress points and ribbing for added rigidity

- Anti-corrosion treatment (e.g., powder coating or galvanization)

- Stable foundation design to prevent deformation over time

A durable steel structure ensures consistent veneer thickness, reduces maintenance needs, and extends the machine’s service life.

Motor Brand (e.g., Siemens, Mitsubishi)

The motor is a core component that drives performance and energy efficiency. Reputable brands like Siemens and Mitsubishi are industry benchmarks for reliability, precision, and long-term durability. Evaluate:

- Use of original branded motors (verify serial numbers if possible)

- Motor power rating matching production requirements

- Efficiency ratings (e.g., IE3 or higher)

- Thermal protection and low-noise operation

Choosing a machine equipped with motors from trusted manufacturers ensures stable performance, lower downtime, and better control over veneer slicing speed and accuracy.

PLC Control System

A sophisticated PLC (Programmable Logic Controller) system is crucial for automation, precision, and ease of operation. High-end machines typically use PLCs from leading brands such as Siemens, Mitsubishi, or Omron. Key aspects to check:

- User-friendly HMI (Human-Machine Interface) with touchscreen controls

- Programmable settings for different wood types and veneer thicknesses

- Real-time diagnostics and fault alerts

- Data logging and production monitoring capabilities

An advanced PLC system enhances operational consistency, reduces operator error, and allows for quick changeovers and process optimization.

Spare Parts Availability

Long-term machine reliability heavily depends on the accessibility of replacement parts. A high-quality machine should come with strong after-sales support. Consider:

- Availability of critical spare parts (blades, rollers, belts, sensors)

- Manufacturer or supplier network with local or regional warehouses

- Clear documentation (parts lists, manuals, exploded diagrams)

- Ongoing technical support and service agreements

Easy access to spare parts minimizes downtime during breakdowns and ensures the machine remains productive over its operational lifespan.

By thoroughly evaluating these four pillars—Steel Structure Durability, Motor Brand, PLC Control System, and Spare Parts Availability—you can confidently identify a high-quality wood veneer machine that delivers performance, reliability, and long-term value.

Guide for Importing Wood Veneer Machines from China: Voltage, Installation, Warranty, and Spare Parts

When importing wood veneer machines—such as veneer cutters, slicers, or rotary log slicers—from China, it’s essential to understand key operational and support specifications to ensure smooth integration into your production setup. Below is a detailed guide covering voltage requirements, installation support, warranty terms, and spare blade/part kits.

Voltage Requirements (380V/220V)

Most industrial wood veneer machinery manufactured in China operates on 380V three-phase power, which is standard in Chinese factories and industrial zones. However, voltage compatibility with your local electrical system is critical:

- Confirm Machine Voltage: Specify your required voltage (380V or 220V) when placing the order. Many Chinese suppliers can customize the motor and electrical components to match your country’s standards.

- Voltage Converters/Transformers: If your facility uses 220V single-phase power, you may need a step-down transformer or phase converter. Discuss this with the supplier to ensure the machine can be adapted.

- Electrical Compliance: Ensure the machine meets safety and electrical standards in your destination country (e.g., CE, UL, or local certifications).

- Ask for Specifications: Request detailed electrical schematics and nameplate data before shipment.

Installation Support

Proper installation is vital for machine performance and safety. Consider the following support options:

- On-Site Installation: Many Chinese suppliers offer technician dispatch services for on-site setup, calibration, and operator training. This service may be included or available for an additional fee.

- Remote Support: If on-site service is not feasible, suppliers often provide video calls, manuals, and real-time troubleshooting via messaging or video conferencing.

- Pre-Installation Requirements: Confirm foundation, space, power supply, and ventilation needs with the supplier prior to delivery.

- Training: Ensure the supplier includes operational and maintenance training for your team, either in China or at your facility.

Warranty Terms

Warranty coverage varies by manufacturer, so clarify the terms before finalizing the purchase:

- Standard Warranty: Most machines come with a 12-month warranty covering defects in materials and workmanship.

- Exclusions: Wear parts (e.g., blades, belts, bearings) and damage from improper use, lack of maintenance, or incorrect voltage are typically not covered.

- Service Response: Confirm how warranty claims are handled—remote support, part replacement, or technician dispatch.

- Extended Warranty: Some suppliers offer extended warranty options for an additional cost.

- Documentation: Request a written warranty certificate and terms in English.

Spare Blade and Part Kits

Having spare components on hand minimizes downtime. Plan accordingly:

- Spare Blade Kits: Essential for veneer cutting machines. Ask the supplier to include an initial set of spare blades (e.g., 2–4 sets) with your order.

- Common Wear Parts: Request a recommended spare parts list, including blades, pressure rollers, belts, bearings, and alignment components.

- Kit Availability: Many suppliers offer pre-packaged “maintenance kits” at a discounted rate.

- Lead Time for Reorders: Confirm how quickly spare parts can be shipped from China and consider keeping a 6–12 month supply on hand.

- Compatibility: Ensure all spare parts are compatible with your machine model and future service needs.

By addressing voltage compatibility, securing installation support, understanding warranty coverage, and stocking essential spare parts, you can ensure a successful and efficient integration of your imported wood veneer machine into your production line. Always communicate clearly with your Chinese supplier and document all agreements in writing.

In conclusion, sourcing a wood veneer machine manufacturer in China can offer significant cost advantages and access to advanced manufacturing capabilities. However, it is crucial to conduct thorough due diligence to ensure quality, reliability, and compliance with international safety standards. A key factor in this process is verifying that the manufacturer holds valid CE certification, which confirms that the machinery meets essential health, safety, and environmental protection requirements within the European Economic Area. Beyond documentation, it is highly recommended to insist on testing the machine before shipment—ideally through a video inspection or third-party quality control service—to verify its performance, precision, and operational readiness. Taking these steps not only minimizes risks but also ensures that the equipment will integrate smoothly into your production process, delivering long-term value and operational efficiency.