In today’s competitive woodworking industry, sourcing reliable plywood cold press machinery is critical to ensuring high productivity, consistent output quality, and long-term operational efficiency. As demand for precision-engineered solutions grows, Chinese manufacturers continue to set the benchmark in delivering durable, cost-effective cold press machines that combine advanced technology with robust construction. This 2026 review highlights the top eight manufacturers leading the market with innovative designs, proven performance, and strong manufacturing capabilities—making them trusted partners for businesses focused on efficiency and scalability in plywood production.

Top 8 Plywood Cold Press Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Cold Press Machine Manufacturers Suppliers Factory

Official Website: focus-mach.com

FOCUS MACH is one of the most professional cold press machine manufacturers and suppliers in China, featured by quality products and good price….

#2 Cold Press Plywood Press Machine from China manufacturer

Official Website: 3mjx.com

Made of fabricated steel, the cold press machine can be installed anywhere on the floor of the factory without occupying too much space. Availability: Quantity:….

#3 China Cold Press, Hydraulic Press, Plywood Machine Manufacturer …

Official Website: plywoodmachineline.com

Cold press machine’s pressure can be 400ton, 500ton and 600ton, for standard plywood size 4*8feet, 500ton cold press are good and enough….

#4 Biesse

Official Website: biesse.com

Biesse is an international company producing lines, machines and components for the industrial processing of wood, glass, stone, polymers and composites….

#5 Cold press plywood press machine

Official Website: ply-machine.com

Plywood cold press machine I 3/4/5 layers cold press 500T with automatic loading for plywood making Main Features ○ Reasonable design and good processing ……

#6 Hydraulic Cold Press Machine

Official Website: sunengineersindia.com

A Plywood Sunmica Cold Press Machine is used to bond sunmica (decorative laminate) to plywood, MDF, or flush doors using high pressure without heat….

#7 Automatic Hydraulic Cold Press Machine 50 Ton

Official Website: gurukrupahydraulic.com

Capacity: 50 Ton · Type of Machine: Plywood Machine · Automation Grade: Semi Automatic · Size: 2500 X 1300 · Usage/Application: Plywood Sheet Fixing · Material: Iron….

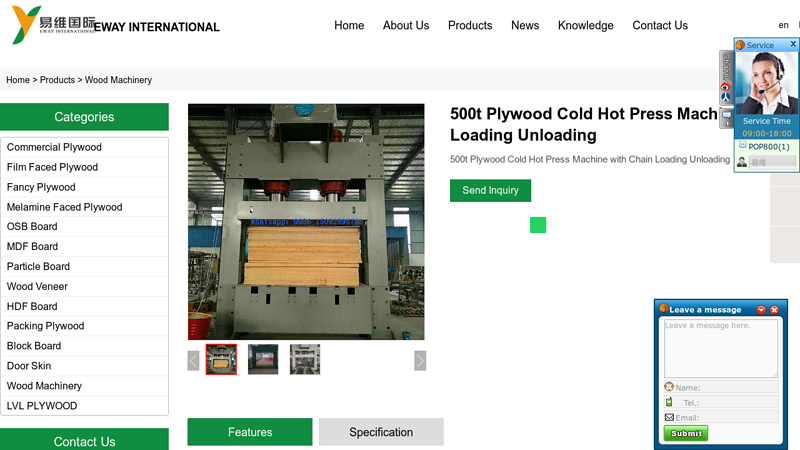

#8 500t Plywood Cold Hot Press Machine with Chain Loading Unloading

Official Website: ewaywood.com

Condition:New,Pressure:500T. Place of origin:Shandong china(Mainand),Brand Name:EWAY. Voltage:Cusomized.Power(W):11kw. Dimension(L*W*H):3600*1370*4100MM OR ……

Professional Buying Guide: Plywood Cold Press Machinery

2026 Global Market Trends for Plywood Cold Press: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

As the global demand for sustainable and cost-effective wood-based panels continues to rise, the plywood industry is undergoing a significant transformation. By 2026, the cold press segment of plywood manufacturing is expected to evolve rapidly in response to technological advancements and economic pressures. Key drivers shaping this evolution include automation, energy efficiency, high-speed production, and labor cost reduction. These factors are not only improving operational efficiency but also enhancing competitiveness in an increasingly globalized market.

Automation in Plywood Cold Press Systems

Automation is becoming a cornerstone of modern plywood manufacturing, especially in cold press operations where precision and consistency are critical. By 2026, the integration of smart technologies such as programmable logic controllers (PLCs), robotic material handling, and AI-driven quality control systems will be standard across mid- to high-end production facilities.

Automated cold press lines enable seamless coordination between veneer sorting, glue application, stacking, pressing, and post-press handling. Real-time monitoring systems reduce human error and optimize press parameters based on veneer thickness, moisture content, and adhesive type. This results in reduced material waste and higher product uniformity. Countries like Germany, Japan, and South Korea are leading the adoption of fully automated cold press solutions, while emerging markets in Southeast Asia and Eastern Europe are rapidly following suit.

The increasing availability of modular automation packages is also making it easier for smaller manufacturers to upgrade their systems incrementally, lowering the barrier to entry and promoting wider adoption across the industry.

Energy Efficiency as a Competitive Advantage

Energy efficiency is emerging as a key differentiator in the 2026 plywood cold press market. Unlike hot pressing, cold pressing relies on chemical curing of adhesives rather than thermal energy, inherently consuming less power. However, the broader manufacturing line—including drying, conditioning, and material handling—still contributes significantly to energy consumption.

Manufacturers are investing in energy-efficient motors, variable frequency drives (VFDs), and heat recovery systems to minimize their carbon footprint and comply with tightening environmental regulations, particularly in the EU and North America. Additionally, the shift toward low-energy adhesives, such as polyurethane (PUR) and hybrid systems that cure at ambient temperatures, further enhances the energy efficiency of cold press operations.

By 2026, energy-efficient cold press lines are expected to become a selling point for environmentally conscious buyers and a compliance requirement in green building certifications like LEED and BREEAM.

High-Speed Production to Meet Growing Demand

Global demand for plywood—driven by construction, furniture, and packaging industries—is projected to grow at a CAGR of 5.2% through 2026. To meet this demand without proportionally increasing facility size or overhead, manufacturers are focusing on high-speed cold press technologies.

Modern cold press systems now feature rapid cycle times, high-precision alignment mechanisms, and automated stack delivery systems that can process hundreds of panels per shift. Innovations such as continuous cold pressing (CCP) and semi-continuous systems are enabling non-stop operation with minimal downtime. These high-speed systems are particularly advantageous for thin plywood and specialty panels used in interior design and cabinetry.

China, India, and Vietnam are leading in the deployment of high-speed lines due to their large-scale production needs and export-oriented manufacturing. As equipment costs decline and reliability improves, high-speed cold pressing is expected to become more accessible to medium-sized producers.

Labor Cost Reduction Through Technological Integration

Labor costs are a significant portion of operational expenses in the plywood industry, particularly in regions with rising wages and labor shortages. By 2026, reducing reliance on manual labor through integrated technological solutions will be a primary objective for cold press manufacturers.

Automated glue spreaders, robotic stackers, and AI-powered inspection systems reduce the need for direct human intervention in high-risk or repetitive tasks. This not only lowers labor costs but also improves workplace safety and product consistency. In countries like the United States and Germany, where labor is expensive and scarce, fully automated cold press lines can reduce manpower requirements by up to 60%.

Even in lower-wage regions, manufacturers are investing in automation to future-proof operations against anticipated increases in labor costs and to maintain export competitiveness. Training programs and partnerships with equipment suppliers are helping ease the transition, ensuring that existing workforces can manage and maintain advanced systems.

Conclusion

By 2026, the global plywood cold press market will be defined by a convergence of automation, energy efficiency, high-speed production, and labor cost optimization. These trends are driven by technological innovation, economic pressures, and sustainability goals. Manufacturers who proactively adopt these advancements will gain a strategic advantage in terms of cost, quality, and environmental compliance. As the industry evolves, cold pressing is poised to become not only a niche alternative but a mainstream solution in the future of sustainable wood panel production.

How to Evaluate a High-Quality Plywood Cold Press

When investing in a plywood cold press, ensuring long-term reliability, efficiency, and minimal downtime is crucial. A thorough evaluation should focus on key components that directly impact performance and operational costs. Below are the critical check points to assess a high-quality plywood cold press:

Steel Structure Durability

The steel frame forms the backbone of the cold press and must withstand high pressure and continuous operation. Look for:

– Thick, High-Tensile Steel: The main frame and platen should be constructed from robust, low-carbon or alloy steel with sufficient thickness (typically 30mm or more for critical components).

– Welding Quality: Check for uniform, stress-relieved welding with no cracks or distortions. Professional fabrication with heat treatment ensures long-term structural integrity.

– Rigidity and Alignment: A well-designed structure minimizes deflection under load, ensuring even pressure distribution across the entire pressing surface and consistent panel quality.

Motor Brand and Performance (e.g., Siemens/Mitsubishi)

The hydraulic and drive motors significantly influence efficiency, energy consumption, and reliability.

– Reputable Motor Brands: Motors from globally recognized brands like Siemens, Mitsubishi, ABB, or SEW offer proven durability, energy efficiency, and precise control.

– Rated Power and Duty Cycle: Ensure the motor power matches the press size and production requirements. Continuous-duty motors prevent overheating during extended operation.

– Protection and Cooling: IP55 or higher protection ratings and efficient cooling systems enhance motor lifespan, especially in humid or dusty mill environments.

PLC Control System

Modern cold presses rely on PLC (Programmable Logic Controller) systems for automation, precision, and ease of operation.

– Established PLC Brands: Systems from Siemens (S7 series), Mitsubishi (FX/Q series), or Omron provide stable, user-friendly interfaces with advanced diagnostics.

– Customizable Pressing Programs: The PLC should support programmable pressure, time, and stroke settings for different plywood grades and thicknesses.

– Touchscreen HMI (Human-Machine Interface): An intuitive display allows operators to monitor parameters, log data, and troubleshoot issues quickly.

– Safety Interlocks and Alarms: Integrated safety features prevent accidents and protect machine components.

Spare Parts Availability

Long-term operational efficiency depends on the ease and speed of maintenance.

– Local or Global Support Network: Choose a manufacturer or supplier with a strong distribution network offering readily available spare parts such as seals, hoses, valves, sensors, and hydraulic components.

– Standardized Components: Systems using common industrial components (e.g., ISO-standard hydraulic fittings) reduce dependency on proprietary parts.

– Technical Documentation and Support: Availability of detailed manuals, wiring diagrams, and responsive technical assistance ensures faster repairs and reduced downtime.

By carefully evaluating these four key areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can select a high-quality plywood cold press that delivers consistent performance, lower maintenance costs, and a strong return on investment.

Guide for Importing Plywood Cold Press from China

Voltage Requirements (380V/220V)

When importing a plywood cold press from China, it’s critical to verify the machine’s electrical specifications to ensure compatibility with your local power supply. Most industrial cold presses in China are manufactured to operate on 380V, 3-phase, 50Hz power systems, which is standard for Chinese factories. However, some smaller or customized models may be available in 220V, single-phase configurations.

- Confirm Voltage Needs: Clearly specify your required voltage (380V or 220V) when placing the order. If your facility uses 220V, ensure the supplier can configure the motor and control panel accordingly.

- Transformer Consideration: If the machine is 380V and your local supply is 220V (or vice versa), you may need a step-up or step-down transformer. Discuss this with your supplier to determine if the machine includes voltage adaptability or requires external equipment.

- Electrical Compliance: Verify that the machine meets international electrical safety standards (e.g., CE, ISO) and includes proper documentation for customs clearance and local installation.

Installation Support

Proper installation is essential for optimal performance and safety. Most Chinese manufacturers offer varying levels of installation support, but terms should be clarified before purchase.

- On-Site Installation: Some suppliers offer technician dispatch services where an engineer travels to your location to install and commission the machine. This service often incurs additional costs for travel, accommodation, and labor.

- Remote Guidance: Many suppliers provide detailed installation manuals, wiring diagrams, and video tutorials. They may also offer real-time support via video calls (e.g., Zoom, WeChat) to guide your team through setup.

- Pre-Shipment Testing: Reputable suppliers conduct pre-shipment testing and may provide a video demonstration of the machine running to ensure it’s operational before shipping.

- Local Technician Coordination: Consider hiring a local industrial machinery technician to assist with mechanical leveling, electrical connections, and safety checks during installation.

Warranty Terms

Warranty conditions vary significantly between Chinese manufacturers. It’s important to negotiate and document warranty terms clearly in your contract.

- Standard Warranty Period: Most suppliers offer a 12-month warranty from the date of shipment, covering defects in materials and workmanship.

- Coverage Details: The warranty typically includes key components such as the hydraulic system, frame, and control panel. However, wear-and-tear parts (e.g., seals, hoses, blades) may be excluded.

- Exclusions: Damage caused by improper installation, incorrect voltage, misuse, or lack of maintenance is generally not covered.

- After-Sales Service: Confirm whether the supplier offers spare parts replacement during the warranty period and how claims are processed. Some suppliers may ship replacement parts via express delivery at no cost if under warranty.

- Extended Warranty Options: Inquire about extended warranty packages for longer coverage, especially if shipping and downtime costs are high.

Spare Blade and Part Kits

Due to potential delays in international shipping, it’s highly recommended to order spare blades and critical spare parts at the time of machine purchase.

- Spare Blades: Cold press machines use steel blades that wear over time. Order at least 2–3 spare blades depending on your production volume. Confirm blade dimensions and material compatibility with your plywood type.

- Spare Parts Kit: Request a comprehensive spare parts kit that includes:

- Hydraulic seals and O-rings

- Pressure valves and gauges

- Electrical fuses and relays

- Belts and connectors

- Common fasteners and mounting hardware

- Customization: Ensure spare parts are compatible with your specific machine model. Provide the machine’s serial number or model code when ordering spares.

- Stocking Strategy: Maintain a local inventory of critical spares to minimize downtime. Discuss with your supplier about future part availability and lead times for reordering.

By addressing voltage compatibility, securing clear installation support, understanding warranty terms, and stocking essential spare parts, you can ensure a smooth and efficient integration of your imported plywood cold press into your production line.

In conclusion, sourcing a plywood cold press machine from China can offer significant cost advantages and access to advanced manufacturing technology. However, to ensure a successful procurement process, it is essential to prioritize quality, safety, and compliance. Buyers should thoroughly verify that the machine comes with a valid CE certification, as this confirms that it meets European safety, health, and environmental standards—serving as a strong indicator of overall build quality and reliability. Additionally, arranging a pre-shipment inspection or factory acceptance test is highly recommended to evaluate the machine’s performance, functionality, and operational efficiency before it leaves the supplier’s facility. Taking these critical steps helps mitigate risks, avoid potential delays or defects upon arrival, and ensures that the investment delivers long-term value and productivity. By emphasizing certification and hands-on testing, buyers can confidently source a high-performing cold press machine that meets both technical requirements and international safety standards.