In the competitive world of woodworking and panel processing, choosing the right plywood sanding machine is critical for achieving precision, efficiency, and long-term durability. As demand for high-quality surface finishing grows, manufacturers are turning to advanced solutions that combine robust engineering with cost-effective performance. China’s manufacturing sector continues to lead in delivering innovative, reliable machinery, leveraging cutting-edge technology and scalable production capabilities. This 2026 review highlights the top eight plywood sanding machine manufacturers known for their operational excellence, rugged build quality, and strong reputation in global B2B markets.

Top 8 Plywood Sanding Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 Plywood Sanding Machine

Official Website: hanvymachinery.com

As one of the leading plywood sanding machine manufacturers and suppliers in China, and equipped with a productive factory, welcome to import plywood sanding ……

#2 China Plywood Machine Manufacturer & Factory

Official Website: plywoodmachineline.com

The plywood sander is mainly used for fine sanding and re-polishing on the surface of plywood, various multi-layer boards, blockboard, particle board, medium ……

#3 Plywood Sanding and Calibrating Machine Manufacturer

Official Website: kumarengineeringco.in

Kumar Engineering India Pvt. Ltd. manufactures plywood & laminate sanding, calibrating, dd saw and other wood working machines, delivering precision ……

#4 Biesse

Official Website: biesse.com

Biesse is an international company producing lines, machines and components for the industrial processing of wood, glass, stone, polymers and composites….

#5 Sanding Machines

Official Website: hicasmach.com

20.18m/s Sanding Paper Speed 380V 50HZ 3phase Plywood Sanding Machine for Solid Wood Processing Plant · Read More ……

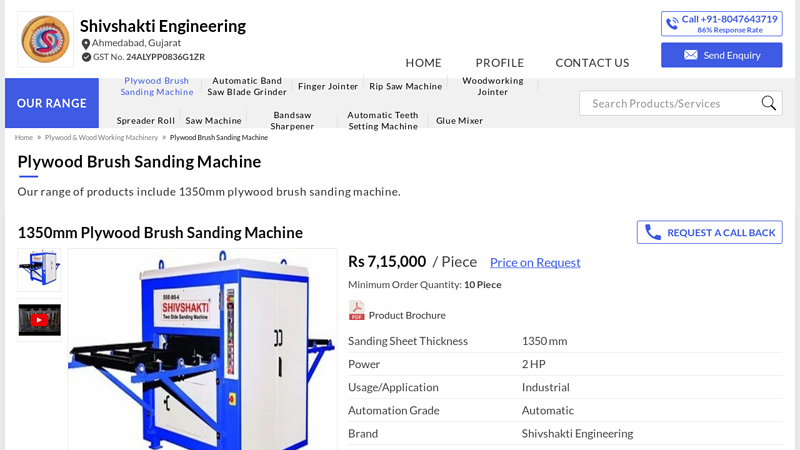

#6 1350mm Plywood Brush Sanding Machine

Official Website: shivshaktiplywoodmachine.com

A Plywood Brush Sanding Machine is designed to achieve a uniform and smooth finish on plywood, block board, flush doors, and other wooden panels. Unlike ……

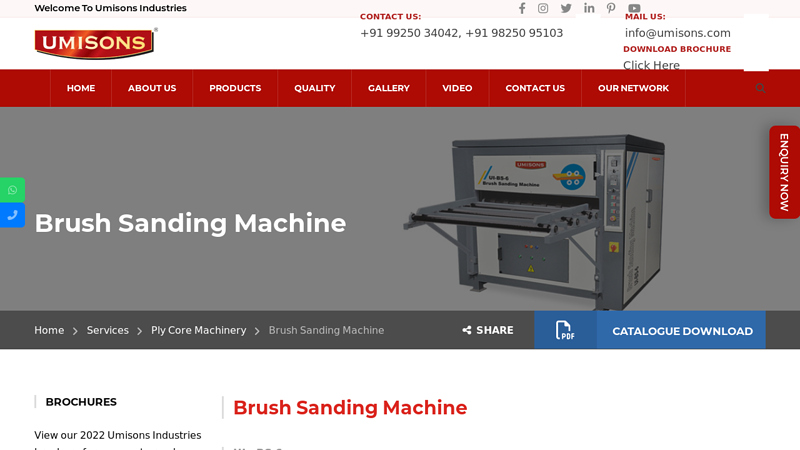

#7 Plywood Brush Sanding Machine Manufacturer in Ahmedabad, India

Official Website: umisons.com

Available in Automatic & Semi Automatic Model · Brush Sanding Machine is specially developed for uniform sanding operation on plywood, block board and flush door ……

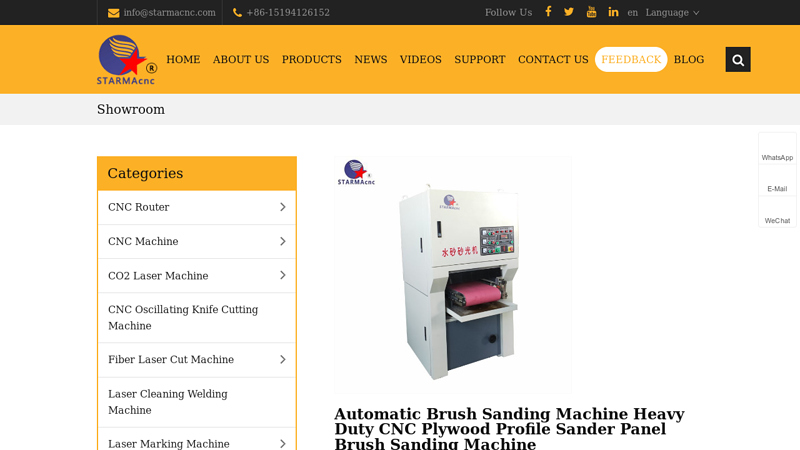

#8 Automatic Brush Sanding Machine Heavy Duty CNC Plywood …

Official Website: starmacnclaser.com

Model: SM-400MS Views: 10008. Working size: Maximum width 400mm. Color: Can customized. Price range: $6580-$7380/set According to configurations…

Professional Buying Guide: Plywood Sanding Machinery

2026 Global Plywood Sanding Market Trends: Automation, Efficiency, and Cost Pressures

The global plywood sanding market is poised for significant transformation by 2026, driven by intensifying pressures on manufacturers to enhance productivity, reduce costs, and meet sustainability mandates. Key technological and economic forces—Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction—are converging to reshape sanding processes. Here’s an analysis of these critical trends:

Automation: The Driving Force for Precision and Throughput

Automation is rapidly moving from a competitive advantage to a necessity in plywood sanding by 2026. The primary drivers are the need for consistent quality, reduced human error, and integration within fully automated production lines.

- Intelligent Sanding Systems: Expect widespread adoption of sanding lines featuring AI-powered vision systems and machine learning algorithms. These systems will continuously analyze surface defects in real-time, automatically adjusting sanding pressure, grit progression, and feed speed for optimal material removal and surface finish, minimizing waste and rework.

- Robotic Integration: Robotic arms equipped with advanced sanding end-effectors will handle complex edge sanding, profiling, and finishing tasks previously done manually, especially for custom or irregular panels. This improves consistency and safety.

- Predictive Maintenance: Sensor networks embedded in sanders will monitor vibration, temperature, and belt wear, feeding data to predictive maintenance platforms. This minimizes unplanned downtime and optimizes consumable replacement schedules, maximizing line availability.

- Seamless Line Integration: Sanding units will be designed for plug-and-play integration with upstream (pressing, trimming) and downstream (coating, sorting) equipment via standardized communication protocols (e.g., OPC UA), enabling true lights-out operation.

Energy Efficiency: Sustainability as a Competitive Imperative

Rising energy costs and stringent environmental regulations (e.g., EU Green Deal, carbon pricing initiatives) are making energy efficiency a core design and operational requirement for 2026.

- High-Efficiency Motors & Drives: Adoption of IE4/IE5 super-premium efficiency motors and advanced Variable Frequency Drives (VFDs) will become standard. These technologies dynamically match motor power to the actual sanding load, significantly reducing energy consumption during idle, light-load, or varying production rates.

- Optimized Dust Collection: Energy-intensive dust extraction systems are a major focus. Trends include:

- Smart Dust Control: Systems using sensors to detect dust generation levels and automatically modulate fan speed (via VFDs), drastically cutting fan energy use.

- High-Efficiency Filtration: Wider use of pulsed-jet cartridge filters with lower pressure drops compared to traditional baghouses, reducing the energy required for air movement.

- Heat Recovery: Capturing waste heat from compressed air systems (used in some actuation) or motor enclosures for pre-heating processes or facility heating.

- Regenerative Braking: High-speed automated lines will increasingly utilize regenerative drives that feed energy back into the grid when decelerating heavy conveyor sections, further improving overall efficiency.

- Lifecycle Analysis (LCA): Manufacturers will demand sanding equipment with demonstrably low total energy consumption over its lifecycle, influencing procurement decisions.

High-Speed Production: Meeting Demand with Precision

The demand for faster throughput without sacrificing quality is relentless. By 2026, “high-speed” will be the baseline expectation for new installations in competitive markets.

- Advanced Conveyor Systems: Development of more robust, stable, and precisely controlled conveyor systems (e.g., twin-belt, segmented) capable of reliably handling speeds exceeding 100 meters per minute while maintaining panel flatness and consistent sanding pressure.

- High-Frequency Sanding Heads: Implementation of sanding heads operating at significantly higher frequencies (e.g., >150 Hz) enables finer surface finishes at high speeds by increasing the number of sanding grains contacting the surface per unit time.

- Optimized Abrasive Technology: Development of ultra-durable, heat-resistant abrasive belts and discs specifically engineered for sustained high-speed operation, reducing changeover frequency and maintaining consistent cut rates. This includes advanced backing materials and bonding agents.

- Multi-Stage Integration: More complex sanding lines will integrate multiple stages (e.g., coarse, fine, fine-fine) within a single compact footprint, minimizing handling time and enabling continuous high-speed processing from rough to final finish.

- Real-Time Process Control: High-speed lines will rely heavily on real-time feedback loops (vision, load sensors) to instantly correct for variations in feed speed or panel density, ensuring quality isn’t compromised at speed.

Labor Cost Reduction: The Imperative for Competitiveness

Escalating labor costs, particularly in North America, Europe, and parts of Asia, coupled with persistent labor shortages in manufacturing, make reducing direct labor in sanding a critical business objective by 2026.

- Automation as the Primary Tool: The automation trends mentioned above (robotic sanding, AI control, predictive maintenance) are the most direct path to labor reduction. Automated lines require significantly fewer operators for monitoring and oversight compared to manual or semi-automated setups.

- Remote Monitoring & Diagnostics: Cloud-based platforms will allow technicians and engineers to monitor machine health, performance, and even adjust parameters remotely, reducing the need for on-site specialists and enabling faster troubleshooting over larger geographical areas.

- Simplified Operation & Maintenance: Equipment design will prioritize ease of use: intuitive HMI interfaces, guided maintenance procedures with AR (Augmented Reality) support, and modular components for quick changeover, reducing the skill level and time required for operation and upkeep.

- Focus on Value-Added Roles: As routine sanding tasks are automated, the workforce will shift towards higher-value activities: data analysis for process optimization, overseeing multiple automated lines, managing quality assurance systems, and performing preventative maintenance.

- Total Cost of Ownership (TCO) Focus: Investment decisions will be heavily weighted towards solutions offering the lowest TCO, where the significant reduction in ongoing labor costs justifies higher upfront capital expenditure on advanced automated systems.

Conclusion: By 2026, the global plywood sanding landscape will be defined by highly automated, energy-optimized, high-speed production lines. Success will depend on the seamless integration of AI-driven control, advanced mechanics, and sustainable practices. Manufacturers who proactively invest in technologies enabling significant labor cost reduction through automation and efficiency will gain decisive competitive advantages in terms of cost, quality, consistency, and sustainability, while those relying on outdated manual or semi-automated processes will face increasing economic pressure. The convergence of these four trends points towards a future of smarter, faster, greener, and more cost-effective plywood sanding.

Key Evaluation Criteria for High-Quality Plywood Sanding Machines

When assessing the quality and performance of a plywood sanding machine, several critical components determine its efficiency, longevity, and reliability. Below are the essential check points to consider:

Steel Structure Durability

A robust steel frame is foundational to the machine’s stability and precision. High-quality plywood sanding machines use thick, reinforced steel constructions to minimize vibration during operation. Look for machines with anti-corrosion treatments and welded structures designed to withstand continuous industrial use. A durable frame ensures consistent sanding results over time and reduces maintenance needs due to misalignment or structural fatigue.

Motor Brand (e.g., Siemens/Mitsubishi)

The motor is the powerhouse of the sanding machine, and its reliability directly impacts performance. Reputable brands like Siemens, Mitsubishi, or ABB offer motors known for high efficiency, thermal protection, and long service life. These motors provide stable speed control, essential for uniform sanding across varying plywood densities. Confirm the motor specifications match the machine’s workload requirements and verify genuine brand certification to avoid counterfeit components.

PLC Control System

A modern plywood sanding machine should integrate a Programmable Logic Controller (PLC) from trusted manufacturers such as Siemens, Mitsubishi, or Omron. The PLC system ensures precise automation of sanding parameters—including feed speed, belt tension, and pressure control—leading to consistent surface finishes. A user-friendly HMI (Human-Machine Interface) allows operators to store sanding recipes, monitor performance, and troubleshoot issues efficiently, enhancing productivity and reducing downtime.

Spare Parts Availability

Long-term operational efficiency depends heavily on the accessibility of spare parts. Choose machines from manufacturers or suppliers with a strong global or regional support network. Common wear parts—such as sanding belts, rollers, bearings, and drive components—should be readily available to minimize production stoppages. Verify if the supplier maintains an inventory of critical spares and offers technical support for quick replacements.

By evaluating these four key areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can confidently select a high-quality plywood sanding machine that ensures durability, precision, and minimal downtime in industrial applications.

Guide for Importing Plywood Sanding Machines from China

When importing plywood sanding machines from China, it’s essential to understand key technical and support specifications to ensure compatibility, reliability, and smooth operation. Below are critical aspects to consider:

Voltage Requirements (380V/220V)

Chinese-manufactured plywood sanding machines are commonly built to operate on industrial voltage standards. Confirm the machine’s voltage compatibility with your local electrical infrastructure:

- Standard Options: Most machines are available in 380V 3-phase (common in industrial settings) or 220V single-phase (suitable for smaller workshops).

- Customization: Many Chinese suppliers can customize machines to match your country’s voltage and frequency (e.g., 60Hz for North America vs. 50Hz in most of Asia and Europe).

- Verification: Always request machine nameplate specifications and confirm with the supplier whether a transformer or voltage converter will be needed upon import.

Installation Support

Ensure the supplier offers comprehensive installation assistance to minimize downtime upon arrival:

- On-Site Installation: Some suppliers provide engineers who can travel to your location for setup and calibration (usually at additional cost).

- Remote Guidance: Many offer video calls, detailed manuals, or step-by-step installation videos.

- Pre-Installation Requirements: Confirm foundation, space, ventilation, and power supply needs in advance. Request a site preparation checklist from the supplier.

Warranty Terms

Warranty conditions vary significantly between manufacturers—clarify these before purchase:

- Standard Coverage: Typically ranges from 12 to 24 months from the date of shipment, covering defects in materials and workmanship.

- Exclusions: Wear parts (e.g., sanding belts, bearings, motors under misuse) are often excluded. Confirm what is covered.

- Service Support: Ask if warranty repairs can be handled locally or require returning parts to China. Some suppliers partner with service agents abroad.

- Response Time: Clarify how technical issues are handled under warranty—email support, video troubleshooting, or on-site service.

Spare Blade/Part Kits

Plan ahead for maintenance with readily available spare parts:

- Included Kits: Many suppliers offer optional spare part kits at purchase, including extra sanding belts, blades, rollers, bearings, and drive components.

- Recommended Stock: Request a list of commonly replaced parts and consider ordering a 6–12 month supply initially, especially if shipping replacement parts may cause delays.

- Long-Term Availability: Confirm that the supplier will continue to support your machine with parts for at least 5 years post-purchase.

By carefully evaluating voltage compatibility, installation support, warranty policies, and spare parts availability, you can ensure reliable performance and reduce operational risks when importing plywood sanding machines from China.

In conclusion, sourcing a plywood sanding machine from China can offer significant cost advantages and access to a wide range of advanced machinery options. However, to ensure quality, safety, and compliance, it is crucial to verify that the machine comes with valid CE certification, confirming that it meets European health, safety, and environmental protection standards. Additionally, arranging for pre-shipment testing—either through a third-party inspection or by visiting the supplier’s facility—helps confirm the machine’s performance, functionality, and adherence to your specifications. Taking these proactive steps minimizes risks, ensures smooth integration into your production process, and safeguards your investment, ultimately leading to a successful and reliable sourcing outcome.