In the competitive landscape of wood processing, veneer drying machines play a pivotal role in ensuring product quality and production efficiency. As demand for precision and consistency grows, manufacturers worldwide are turning to high-performance drying solutions that combine advanced engineering with long-term durability. China’s robust manufacturing ecosystem has emerged as a key hub for innovative and cost-effective machinery, offering global buyers access to cutting-edge technology backed by scalable production capabilities. This 2026 review highlights the top six veneer drying machine manufacturers renowned for their operational efficiency, rugged build quality, and commitment to advancing industrial drying standards in the woodworking sector.

Top 6 Veneer Drying Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

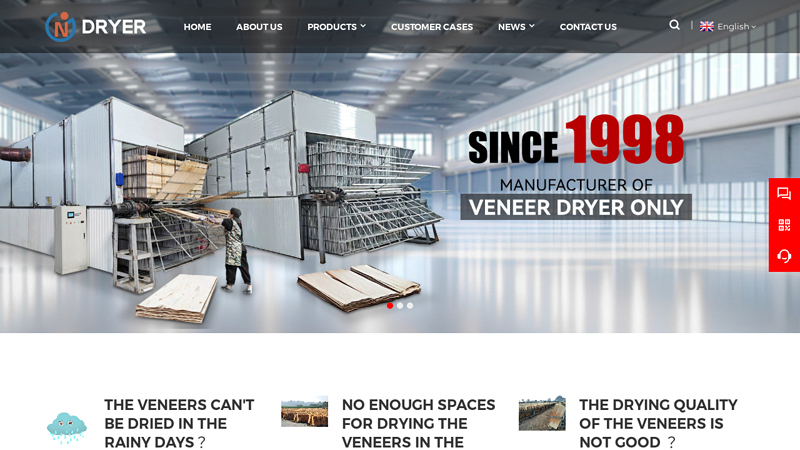

#1 China veneer dryer manufacturer, veneer drying machine supplier …

Founded: 1998

Official Website: veneer-dryer.com

Shandong Linqu Juneng Drying Equipment Co.,Ltd. is a modern enterprise specializing in the R&D and production of different veneer dryers since 1998….

#2 Veneer Drying Machine

Official Website: plywoodmachineline.com

China Veneer Drying Machine manufacturers and wholesalers provide Veneer Machine, Veneer Peeling Lathe, Plywood Machine with high quality and very good ……

#3 veneer roller dryer manufacturers plywood wood veneer drying …

Official Website: yuequnmachinery.com

Rating 5.0 (42) This series of roller dryer is one of the main machines in plywood production line. It is very suitable for wet clipping processing and drying thick veneer….

#4 Raute

Official Website: raute.com

Raute offers services worldwide to maintain existing veneer, plywood, and LVL production machinery and to improve the production. Frontpage of the services ……

#5 Veneer Drying Machine

Official Website: focus-mach.com

FOCUS MACH is one of the most professional veneer drying machine manufacturers and suppliers in China, featured by quality products and good price….

#6 Veneer Drying Technology

Official Website: grenzebach.com

We offer everything from individual dryer plants with manual feeders, to complete veneer drying lines with automatic feeders, scanners and stacking systems….

Professional Buying Guide: Veneer Drying Machinery

2026 Global Market Trends in Veneer Drying: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

As the wood products industry evolves to meet growing demand and sustainability mandates, the veneer drying sector is undergoing significant transformation. By 2026, the global veneer drying market is poised for technological and operational advancements driven by the interplay of automation, energy efficiency, high-speed production, and labor cost reduction. These trends are reshaping manufacturing processes, improving profitability, and aligning with environmental goals.

Automation in Veneer Drying Systems

Automation is becoming a cornerstone of modern veneer drying operations. By 2026, an increasing number of manufacturers are deploying automated control systems, robotics, and AI-driven monitoring to optimize drying cycles and reduce human intervention.

- Smart Sensors and IoT Integration: Automated veneer dryers are incorporating Internet of Things (IoT) sensors that continuously monitor moisture content, temperature, and airflow. Real-time data enables dynamic adjustments to drying parameters, minimizing defects and maximizing yield.

- Automated Loading and Unloading: Robotic arms and conveyor systems are streamlining material handling, reducing bottlenecks and inconsistencies associated with manual processes. This is particularly impactful in large-scale plywood and engineered wood facilities.

- Predictive Maintenance: Machine learning algorithms analyze equipment performance data to predict maintenance needs, reducing unplanned downtime and extending equipment lifespan.

The adoption of automation not only improves product consistency but also allows operators to manage multiple drying lines remotely, significantly boosting operational efficiency.

Energy Efficiency and Sustainable Drying Technologies

With tightening environmental regulations and rising energy costs, energy efficiency has become a critical focus for veneer producers. By 2026, energy-efficient drying technologies are expected to dominate new installations and retrofits.

- Heat Recovery Systems: Advanced heat exchangers are being integrated into drying lines to capture and reuse waste heat, reducing energy consumption by up to 30%. This is especially important in continuous dryers operating at high thermal loads.

- Low-Temperature and Vacuum Drying: Innovations in vacuum and low-temperature drying methods allow for gentler drying of thin veneers, preserving quality while reducing energy use. These systems are gaining traction in premium veneer markets.

- Renewable Energy Integration: Facilities are increasingly powered by biomass, solar, or hybrid energy systems. Using biomass boilers fueled by wood waste from veneer production closes the energy loop and improves sustainability credentials.

Regulatory pressure and carbon pricing mechanisms in regions like the EU and North America are accelerating the shift toward energy-smart drying solutions, making them a competitive necessity by 2026.

High-Speed Veneer Drying for Increased Throughput

To meet global demand for plywood, laminated veneer lumber (LVL), and decorative surfaces, manufacturers are investing in high-speed drying technologies that maximize output without sacrificing quality.

- Continuous Multi-Zone Dryers: These systems allow precise control over drying stages (pre-heat, main drying, conditioning), enabling throughputs exceeding 200 m/min for certain veneer types. By 2026, such systems will be standard in high-volume production environments.

- RF (Radio Frequency) and Impulse Drying: Emerging high-speed technologies like RF drying offer uniform moisture reduction through electromagnetic energy, drastically cutting drying time compared to conventional hot-air methods.

- Digital Twin Simulations: Manufacturers are using digital twins to simulate and optimize drying line configurations before implementation, ensuring maximum speed and efficiency from day one.

These advancements support just-in-time manufacturing and global supply chain responsiveness, positioning high-speed drying as a key differentiator in competitive markets.

Labor Cost Reduction through Technological Integration

Labor costs continue to rise globally, particularly in developed economies and industrializing regions with tightening labor markets. The veneer drying sector is responding with technologies that minimize reliance on manual labor.

- Operator Consolidation: Automated control systems enable a single technician to oversee multiple drying lines, reducing the number of personnel required per shift.

- Remote Monitoring and Control: Cloud-based platforms allow supervisors to monitor drying operations from off-site locations, enabling centralized management of geographically dispersed facilities.

- Reduced Training Needs: With intuitive human-machine interfaces (HMIs) and self-diagnosing systems, even complex drying lines require less specialized labor, lowering training and turnover costs.

In regions like Southeast Asia and South America, where labor availability fluctuates, automation mitigates operational risks and supports consistent production.

Conclusion

By 2026, the global veneer drying market will be defined by a convergence of automation, energy efficiency, high-speed capabilities, and labor optimization. Manufacturers investing in integrated, smart drying systems will gain a significant competitive edge through improved product quality, lower operating costs, and enhanced sustainability. As digitalization and green manufacturing become industry standards, the future of veneer drying lies in intelligent, efficient, and scalable solutions.

How to Evaluate a High-Quality Veneer Drying System: Key Checkpoints

When investing in a veneer drying system, ensuring long-term performance, reliability, and minimal downtime is crucial. A high-quality dryer must combine robust construction, trusted components, intelligent controls, and accessible support. Below are the critical checkpoints to evaluate:

Steel Structure Durability

The steel framework forms the backbone of the veneer dryer and directly impacts its lifespan and operational stability. Evaluate the following:

- Material Quality: Confirm the use of high-grade, corrosion-resistant steel (e.g., galvanized or stainless steel components) to withstand continuous exposure to heat and moisture.

- Welding and Assembly: Inspect weld quality—uniform, clean welds with no cracks or gaps indicate superior craftsmanship.

- Frame Rigidity: Ensure the structure is reinforced to prevent warping or vibration during operation, which could affect veneer quality and machine alignment.

- Anti-Corrosion Treatment: Verify that structural components are treated with protective coatings suitable for humid and high-temperature environments.

Motor Brand and Performance (e.g., Siemens, Mitsubishi)

The motors power critical functions such as conveyor movement, fan systems, and roller drives. High-end brands ensure efficiency, reliability, and longevity.

- Brand Reputation: Prioritize systems equipped with motors from globally recognized manufacturers like Siemens, Mitsubishi, ABB, or SEW. These brands offer proven performance in industrial applications.

- Energy Efficiency: Check for high-efficiency ratings (e.g., IE3 or IE4) to reduce power consumption and operating costs.

- Thermal Protection & Duty Cycle: Ensure motors are designed for continuous operation under high-temperature conditions with built-in thermal overload protection.

- Sealing & Environmental Resistance: Motors should be appropriately rated (e.g., IP55 or higher) to resist dust and moisture ingress.

PLC Control System

A sophisticated PLC (Programmable Logic Controller) system ensures precise drying control, process automation, and ease of troubleshooting.

- PLC Brand: Look for reputable brands such as Siemens (SIMATIC), Mitsubishi (MELSEC), or Allen-Bradley. These offer reliability, scalability, and strong technical support.

- User Interface (HMI): The control panel should feature an intuitive touchscreen HMI allowing for easy parameter adjustment, real-time monitoring, and fault diagnostics.

- Process Control Features: Evaluate capabilities such as zone temperature control, moisture feedback loops, speed synchronization, and recipe storage for different veneer types.

- Connectivity & Data Logging: Advanced systems offer remote monitoring, data export, and integration with factory management systems (e.g., via Ethernet or Modbus).

Spare Parts Availability

Minimizing downtime is essential in continuous production environments. Readily available spare parts are a hallmark of a quality system.

- Local & Global Support Network: Confirm whether the manufacturer or supplier maintains regional service centers and an accessible spare parts inventory.

- Common Component Use: Systems that use standard, off-the-shelf components (e.g., motors, sensors, belts) reduce lead times and costs.

- Documentation & Part Numbering: Request a comprehensive spare parts list with clear identification and supplier references.

- Long-Term Commitment: Choose suppliers who guarantee parts availability for at least 10–15 years, indicating confidence in product lifecycle support.

By thoroughly assessing these four key areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can confidently select a high-quality veneer drying system that delivers consistent performance, reduced maintenance, and a strong return on investment.

Importing Veneer Drying Equipment from China: Key Considerations

Voltage Requirements (380V/220V)

When importing veneer drying equipment from China, verifying electrical compatibility is crucial. Most industrial drying machines manufactured in China operate on 380V, 3-phase, 50Hz power, which is standard for Chinese industrial facilities. However, some smaller or customized units may be built for 220V, single-phase systems. Before placing an order:

- Confirm the exact voltage and phase requirements with the supplier.

- Ensure your facility’s power infrastructure supports the machine’s specifications.

- Request a machine wired for your local voltage if different (e.g., 480V/60Hz in North America). This often requires a custom build or a step-down transformer, which may affect cost and lead time.

Failure to verify voltage compatibility can result in equipment damage or safety hazards.

Installation Support

Chinese manufacturers typically offer varying levels of installation support:

- Basic Support: Includes detailed installation manuals, wiring diagrams, and remote assistance via phone or video call.

- Premium/Optional Support: May include on-site installation by a technician (at additional cost), commissioning services, and operator training.

- Clarify what is included in the purchase price and budget for potential travel and accommodation if on-site support is needed.

- Ensure your team is trained to handle mechanical and electrical setup, or arrange for local industrial electricians familiar with 3-phase systems.

Warranty Terms

Warranty terms vary significantly between suppliers, so review them carefully:

- Standard warranties typically range from 12 to 24 months from the date of shipment or commissioning.

- Coverage usually includes defects in materials and workmanship but excludes wear parts (e.g., belts, heating elements, rollers) and damage from improper use, incorrect voltage, or lack of maintenance.

- Confirm whether warranty claims require return of parts to China or can be resolved locally (e.g., replacement parts shipped promptly).

- Clarify who bears shipping costs for warranty replacements and the expected turnaround time.

Always get the warranty terms in writing and include them in the sales contract.

Spare Blade/Part Kits

To minimize downtime, it’s advisable to order spare parts upfront:

- Request a recommended spare parts kit from the manufacturer, which often includes high-wear items such as blades, rollers, seals, heating elements, and drive belts.

- Blades used in peeling or slicing prior to drying may need periodic replacement—ensure compatibility and availability of spares.

- Stock critical components based on expected usage and lead times for reordering from China.

- Confirm part numbering systems and request English documentation for ease of future ordering.

Proactively securing spare parts ensures continuous operation and reduces dependency on long international shipping times.

In conclusion, sourcing a veneer drying machine from China can offer significant cost advantages and access to advanced manufacturing technologies. However, it is crucial to prioritize quality assurance and compliance to ensure long-term operational efficiency and safety. Buyers should insist on verifying the CE certification of the machine, as it confirms adherence to European health, safety, and environmental protection standards, reflecting the manufacturer’s commitment to quality. Additionally, arranging for thorough testing of the machine before shipment is essential to confirm that it functions as specified and meets performance requirements. Conducting on-site inspections or hiring third-party quality control services can provide added peace of mind. By carefully validating certifications and testing the equipment prior to dispatch, buyers can minimize risks, avoid costly delays, and ensure a reliable and efficient addition to their production process.