In today’s competitive woodworking industry, sourcing high-performance wood veneer machines is critical to maintaining operational efficiency and long-term durability. As demand for precision and automation grows, manufacturers are increasingly turning to China—home to a robust ecosystem of innovative machinery producers known for advanced engineering and scalable production. This 2026 review highlights the top nine manufacturers who combine cutting-edge technology, rugged build quality, and proven performance to deliver solutions that power efficient, high-output veneer processing lines worldwide.

Top 9 Where Can I Buy Wood Veneer Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 Veneer Systems Inc.

Founded: 1977

Official Website: veneersystems.com

Your source for wood veneering tools, supplies, and equipment. Since 1977, Veneer Systems has been dedicated to those working with wood veneer….

#2 Wood Veneer Sheets & Wood Veneer Deals @ Veneer Factoy …

Official Website: veneer-factory-outlet.com

Wood Veneer Sheets Savings And Wood Veneer Deals @ Veneer Factory Outlet.com Plus FREE Tutorials, Videos, FAQ. Selling Entire Stock Wood Veneer. Save Now!…

#3 GL Veneer: Wood Veneer Sheets

Official Website: glveneer.com

GL Veneer is a leading manufacturer of wood veneer sheets, architectural plywood, wood panel and live edge slabs in the United States….

#4 Oakwood Veneer

Official Website: oakwoodveneer.com

Oakwood Veneer is the largest in stock manufacturer of Exotic Wood Veneer Sheets. Shop for Burl Wood Veneer Panels, and Burl Wood Veneer Sheets made in USA….

#5 Columbia Forest Products

Official Website: columbiaforestproducts.com

Discover Columbia Forest Products, North America’s largest manufacturer of sustainable, decorative hardwood plywood and veneers for residential and commercial…

#6 FormWood Industries

Official Website: formwood.com

FormWood Industries is a premium plywood supplier and manufacturer of over 100 wood veneer species, both domestic and exotic….

#7 Natural Veneers: Veneers

Official Website: naturalveneers.com

Natural Veneers is a leading Veneer manufacturer, supplier & exporter. We provide high quality Veneers, Wood veneers, Paper veneers, Veneer Plywood, ……

#8 Supporting Woodworkers for 22 Years!

#9 Decospan

Official Website: decospan.com

Everything you need to know about wood veneer is right here. Discover our application possibilities, explore how to create a woodlook and learn everything about ……

Professional Buying Guide: Where Can I Buy Wood Veneer Machinery

2026 Global Market Trends for Where Can I Buy Wood Veneer: Driven by Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global wood veneer market is undergoing a significant transformation as manufacturers and suppliers respond to increasing demands for efficiency, sustainability, and cost-effectiveness. By 2026, the landscape for “Where Can I Buy Wood Veneer” will be heavily influenced by four interconnected macro-trends: automation, energy efficiency, high-speed production, and labor cost reduction. These forces are reshaping supply chains, production capabilities, and the competitive positioning of suppliers.

Automation and Digital Integration Transforming Production and Sourcing

Automation is rapidly becoming a cornerstone of modern veneer manufacturing, directly impacting where and how buyers source materials. By 2026, leading veneer producers will leverage advanced robotics and AI-driven systems across the entire process—from log debarking and slicing to grading, sorting, splicing, and packaging. Automated optical scanning (AOS) systems will be standard, enabling real-time defect detection and precise quality control, minimizing waste and ensuring consistent product standards. This shift means that buyers seeking high-precision, consistently graded veneers will increasingly turn to automated facilities, often located in industrial hubs with strong technological infrastructure. Furthermore, digital platforms and e-commerce portals will integrate with automated inventory and order fulfillment systems, making online sourcing faster and more reliable. Buyers will prioritize suppliers with transparent digital interfaces that offer real-time tracking and automated reordering capabilities, streamlining procurement.

Energy Efficiency as a Core Competitive and Regulatory Imperative

Energy efficiency is no longer just an environmental goal but a critical economic and regulatory driver in the veneer industry. By 2026, stringent global carbon reduction targets and rising energy costs will compel manufacturers to invest heavily in energy-efficient technologies. This includes modern kiln drying systems with heat recovery, high-efficiency motors, and renewable energy integration (such as biomass from wood waste or solar power). Suppliers that can demonstrate lower carbon footprints through certifications like FSC or PEFC, backed by verifiable energy data, will gain a significant market advantage. Buyers, especially those in environmentally conscious markets like Europe and North America, will increasingly factor in a supplier’s energy efficiency and sustainability practices when deciding “where to buy.” This trend will favor large-scale, vertically integrated producers with the capital to invest in green technologies, potentially consolidating the supplier base and pushing smaller, less efficient operations to adapt or exit.

High-Speed Production Enabling Agility and Volume Responsiveness

The demand for faster turnaround times and just-in-time delivery is driving the adoption of high-speed production lines in the veneer sector. By 2026, continuous rotary peelers and high-speed slicers capable of operating at unprecedented speeds with minimal downtime will be widespread. Coupled with automated handling and real-time process monitoring, these systems allow manufacturers to respond swiftly to fluctuating market demands and custom orders. This capability is particularly crucial for buyers in the furniture, cabinetry, and architectural millwork industries, where design cycles are shortening. As a result, the “where to buy” decision will increasingly favor suppliers with high-throughput capabilities and flexible production scheduling. Buyers will seek partners who can guarantee shorter lead times and handle both large-volume contracts and smaller, customized batches efficiently—capabilities enabled by high-speed automation.

Labor Cost Reduction Through Technology and Operational Optimization

Rising labor costs and workforce shortages, particularly in developed economies, are accelerating the push for labor reduction in veneer production. By 2026, automation will play a pivotal role in minimizing manual labor across cutting, sorting, splicing, and packaging operations. Collaborative robots (cobots) will handle repetitive tasks, while AI-driven systems reduce the need for manual quality inspection. This shift reduces operational costs and mitigates risks associated with labor volatility. Consequently, suppliers in regions with higher wages will remain competitive by investing in automation, while traditional low-cost labor regions will need to enhance productivity through technology to maintain their edge. For buyers, this means evaluating suppliers not just on geographic location but on their technological sophistication and ability to deliver cost-competitive products through optimized labor models. The most attractive suppliers will be those demonstrating a clear strategy for sustainable cost management via automation and efficiency.

In conclusion, by 2026, the global wood veneer market will be defined by technologically advanced, energy-efficient, and highly automated suppliers. Buyers asking “where can I buy wood veneer” will increasingly look toward manufacturers who integrate these four pillars—automation, energy efficiency, high-speed production, and labor cost reduction—into their operations. Success will belong to suppliers who embrace digital transformation and sustainable practices, offering not just material, but reliability, speed, and environmental responsibility.

How to Evaluate a High-Quality Where Can I Buy Wood Veneer? Key Check Points

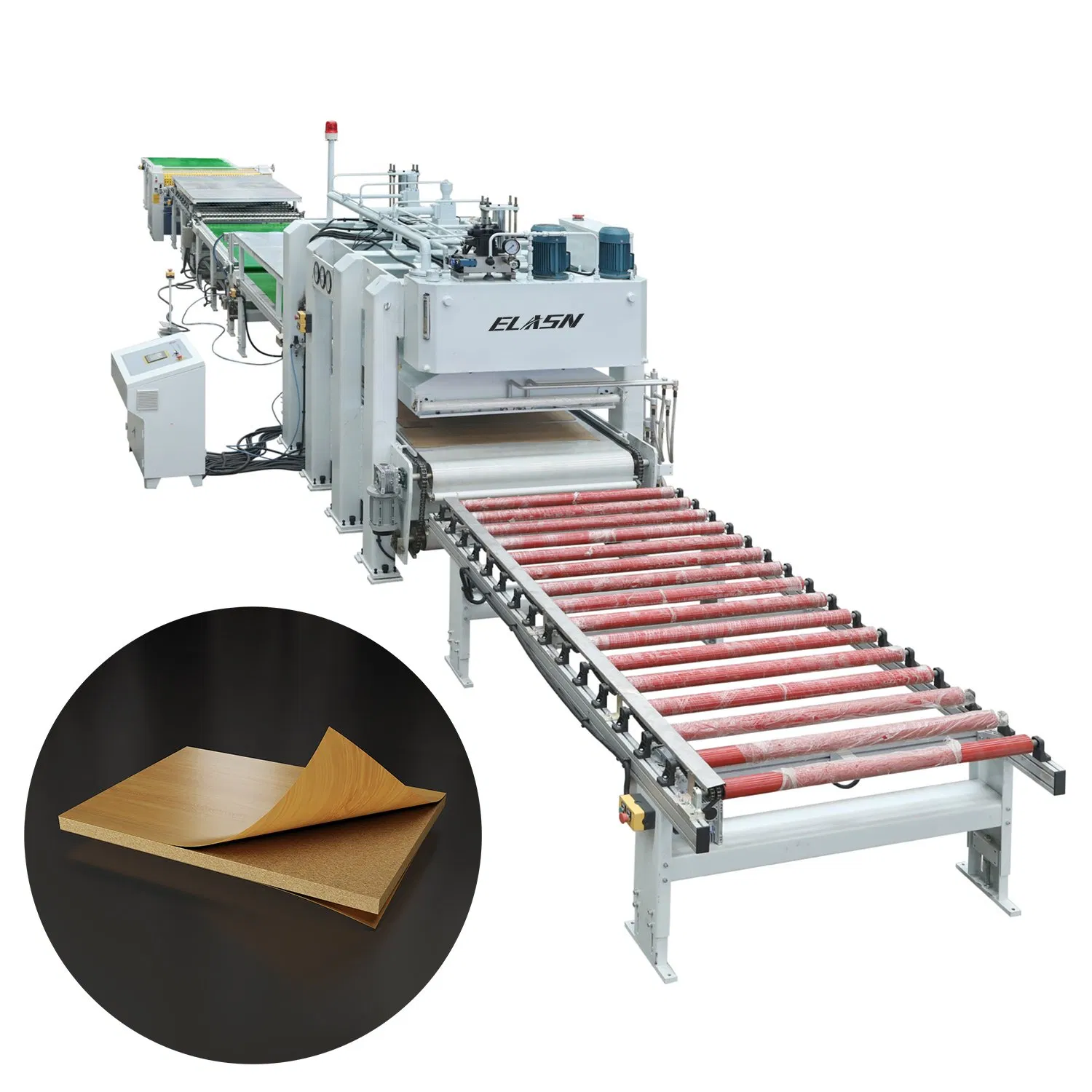

When sourcing wood veneer production equipment—especially core machinery like slicers, dryers, or presses—it’s essential to assess build quality and long-term reliability. Use the following check points to ensure you’re investing in high-performance, durable machinery:

Steel Structure Durability

Evaluate the machine’s frame and support structure for robustness. High-quality wood veneer equipment should feature a heavy-duty steel framework designed to minimize vibration and withstand continuous operation. Look for thick-gauge, welded steel construction with anti-corrosion treatment (such as powder coating or galvanization). A rigid structure ensures precise cutting and consistent veneer thickness over time, reducing maintenance and downtime.

Motor Brand (e.g., Siemens/Mitsubishi)

The performance and longevity of the machine heavily depend on the motor. Reputable brands like Siemens, Mitsubishi, or ABB offer motors known for energy efficiency, reliability, and smooth operation under variable loads. Ensure the motor specifications match the machine’s power requirements and operating conditions. A premium motor brand indicates better engineering integration and longer service life, reducing the risk of unexpected failures.

PLC Control System

A modern wood veneer machine should be equipped with a programmable logic controller (PLC) system from a trusted manufacturer such as Siemens, Omron, or Mitsubishi. The PLC ensures precise control over slicing speed, feed rate, drying temperature, and other critical parameters. Look for user-friendly HMI (Human-Machine Interface) panels, programmable settings, and real-time diagnostics. A robust PLC system enhances automation, improves product consistency, and simplifies troubleshooting.

Spare Parts Availability

Confirm that replacement parts—such as blades, rollers, belts, sensors, and drive components—are readily available and easy to source. Machines from reputable suppliers typically offer global spare parts support and maintain a documented inventory. Ask the vendor about spare parts lead times, local distributor networks, and whether generic or proprietary components are used. Easy access to spare parts minimizes production downtime and supports long-term operational continuity.

By carefully assessing these four critical areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can identify high-quality wood veneer machinery that delivers reliable performance and long-term value.

Guide for Importing Wood Veneer Machines from China: Voltage, Installation, Warranty & Spare Parts

When sourcing wood veneer slicing or peeling machines from China, it’s essential to clarify key technical and support specifications to ensure smooth operation and long-term reliability. Below is a detailed guide covering voltage requirements, installation support, warranty terms, and spare parts availability.

Voltage Requirements (380V/220V)

Chinese industrial machinery is typically manufactured for the domestic power standard of 380V, 3-phase, 50Hz. However, many exporters can customize machines to meet international voltage standards:

- Standard Voltage: Confirm whether the machine is built for 380V 3-phase 50Hz (common in China and many countries) or can be adapted to 220V/240V 1-phase or 3-phase 60Hz (used in regions like North America).

- Customization Options: Request voltage customization at the time of order. Reputable suppliers will reconfigure motors, control panels, and electrical components accordingly.

- Transformer Use: If modifying the machine isn’t feasible, consider using a step-down or step-up transformer, but ensure it matches the machine’s power (kW) rating and has adequate cooling.

- Compliance & Certification: Verify that electrical components meet safety standards such as CE, CCC, or UL, depending on your destination market.

Always provide your local power specifications to the supplier before purchase to avoid costly modifications post-shipment.

Installation Support

Proper installation is critical for performance and safety. Clarify the level of support offered:

- On-Site Installation: Some suppliers offer technician dispatch services for on-site setup, calibration, and operator training. This may incur additional costs for travel, accommodation, and labor.

- Remote Assistance: Many provide installation manuals, wiring diagrams, and video tutorials. Real-time support via video call (e.g., Zoom, WeChat) is commonly available.

- Commissioning Services: Confirm if the supplier includes machine testing and performance validation before shipping (factory acceptance test) and upon installation (site acceptance test).

- Language Support: Ensure technical documentation and support are available in English or your preferred language.

Plan for installation early—factor in potential delays due to visa processing, shipping schedules, or local labor requirements.

Warranty Terms

Warranty coverage varies significantly among Chinese manufacturers. Key points to clarify include:

- Duration: Standard warranties range from 12 to 24 months from the date of shipment or installation.

- Coverage: Typically includes defects in materials and workmanship. Exclusions often apply to wear-and-tear parts (e.g., blades, belts), misuse, improper maintenance, or unauthorized modifications.

- Service Response: Understand how warranty claims are handled—remote troubleshooting, spare parts replacement, or technician dispatch.

- Shipping Costs: Clarify who bears the cost of shipping warranty-covered parts (usually the buyer, unless major component failure).

- Extended Warranty: Some suppliers offer extended coverage for an additional fee, which may include preventive maintenance or priority support.

Always get the warranty terms in writing as part of the sales contract.

Spare Blade and Spare Parts Kits

Regular maintenance and quick access to spare parts are essential for minimizing downtime:

- Spare Blades: Wood veneer machines require frequent blade changes. Confirm if the machine includes a starter blade kit and whether replacement blades are standard or custom-sized.

- Spare Parts Package: Ask suppliers to provide a recommended spare parts kit including belts, bearings, sensors, seals, and electrical components. Many offer kits at a discounted bundled price.

- Availability & Lead Time: Verify parts availability and typical delivery times. Reputable suppliers maintain inventory and can ship globally within 7–14 days.

- Part Compatibility: Ensure spare parts are clearly labeled, and cross-reference part numbers with your machine model.

- Long-Term Support: Confirm the supplier will support your machine with parts for at least 5–10 years post-purchase.

Maintain an inventory of critical spares to avoid production interruptions.

By addressing these four areas—voltage compatibility, installation support, warranty details, and spare parts availability—you can confidently import high-quality wood veneer machinery from China with minimal risk and optimal performance. Always conduct due diligence on suppliers and request references or factory audits if possible.

In conclusion, sourcing wood veneer from China can offer cost-effective and high-quality solutions for your manufacturing or woodworking needs. With numerous suppliers and manufacturers available, it’s essential to conduct thorough due diligence to ensure reliability and product compliance. Always prioritize suppliers who provide CE certification, as this assures that the machinery and materials meet essential health, safety, and environmental protection standards within international markets. Additionally, never overlook the importance of testing the veneer processing machine before shipment—this step ensures the equipment functions as expected and meets your production requirements, minimizing the risk of delays or costly repairs upon arrival. By verifying certifications and conducting pre-shipment inspections, you can build a trustworthy supply chain and achieve consistent, high-quality results from your Chinese wood veneer sources.