In 2026, the demand for high-performance, space-saving wood processing solutions continues to rise—particularly for 2-in-1 veneer peeling machines that combine peeling and slicing functions in a single robust unit. As efficiency and durability become key differentiators in competitive markets, sourcing from China offers unmatched access to innovation, advanced engineering, and scalable production. Leveraging years of specialized manufacturing expertise, leading Chinese producers now deliver integrated machinery that maximizes output while minimizing downtime. This review highlights the top four manufacturers setting new benchmarks in reliability, precision, and operational efficiency for global B2B buyers.

Top 4 2 In 1 Veneer Peeling Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Veneer Peeling Machine Manufacturers, Suppliers and Factory

Official Website: hanvymachinery.com

The veneer peeling machine is the main machine in processing plywood, it could peel wood log core to veneer,high efficiency ,and improves wood utilization….

#2 Veneer Peeling Machine from China Manufacturers

Official Website: lyjinguan.goldsupplier.com

Explore Veneer Peeling Machine products at Linyi Jinguan Import And Export Co., Ltd., reliable China manufacturer. Contact us for more details!…

#3 Raute

Official Website: raute.com

Turn raw logs into real value: consistently, efficiently, profitably with Raute’s Veneer Peeling technologies. · Boost efficiency, minimize downtime, and ……

#4 4 ft Veneer Peeling Machine(single Drive)

Official Website: logpeeling.com

4 ft Veneer Peeling Machine(single Drive). Spindle-less Veneer Peeling Machine. is use for making plywood core veneer….

Professional Buying Guide: 2 In 1 Veneer Peeling Machinery

2026 Global Market Trends for 2-in-1 Veneer Peeling: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global 2-in-1 veneer peeling machine market is poised for significant transformation by 2026, driven by evolving industrial demands, sustainability imperatives, and technological advancements. These machines, which combine rotary cutting and veneer peeling functions into a single integrated system, are increasingly central to the wood processing and engineered wood industries. This analysis focuses on four pivotal trends shaping the market: automation, energy efficiency, high-speed production, and labor cost reduction.

Automation Integration Accelerates

Automation is emerging as the cornerstone of next-generation 2-in-1 veneer peeling systems. By 2026, manufacturers are expected to widely adopt smart manufacturing solutions, including AI-driven control systems, real-time monitoring, and predictive maintenance platforms. These technologies enable machines to self-adjust blade pressure, rotation speed, and log feeding based on material characteristics, minimizing human intervention.

Advanced sensors and computer vision systems will allow automated defect detection and quality classification during peeling, increasing yield and consistency. Integration with Industry 4.0 frameworks—such as cloud-based production dashboards and IoT-enabled equipment—will empower manufacturers to achieve remote operation and centralized control across multiple production lines.

The shift toward automation is particularly pronounced in North America and Western Europe, where labor availability is declining and operational precision is prioritized. Asian manufacturers, especially in China and India, are rapidly adopting automated systems to remain competitive in export markets.

Energy Efficiency Becomes a Competitive Advantage

Sustainability and regulatory pressures are pushing energy efficiency to the forefront of machine design. By 2026, energy-efficient 2-in-1 veneer peeling machines are projected to dominate procurement decisions, particularly in regions with high electricity costs or carbon compliance mandates.

Modern systems are incorporating variable frequency drives (VFDs), regenerative braking, and optimized motor designs to reduce power consumption. Heat recovery systems that repurpose waste energy from motors and compressors are being piloted in pilot facilities and are expected to scale commercially by 2026.

Additionally, manufacturers are exploring hybrid-electric and fully electric drive systems to reduce reliance on fossil-fuel-powered auxiliary equipment. Certification standards such as ISO 50001 and ENERGY STAR are increasingly influencing purchasing decisions, with energy performance becoming a key differentiator in product marketing.

High-Speed Production Meets Demand for Scalability

Global demand for engineered wood products—such as plywood, LVL, and decorative panels—is rising due to urbanization and construction growth in emerging economies. To meet this demand, 2-in-1 veneer peeling machines are being engineered for higher throughput without compromising veneer quality.

By 2026, top-tier models are expected to achieve peeling speeds exceeding 120 meters per minute, supported by reinforced spindles, advanced blade-cooling mechanisms, and dynamic load balancing. High-speed production is being enabled by innovations in material handling, including automated log infeed and continuous veneer stacking systems.

These improvements allow manufacturers to scale operations efficiently, reducing downtime between batches and supporting just-in-time production models. In countries like Vietnam, Indonesia, and Brazil—where wood processing industries are expanding rapidly—high-speed machines are critical for maintaining cost competitiveness in global supply chains.

Labor Cost Reduction Through Smart Design and Digitalization

Labor cost reduction remains a primary driver in the adoption of advanced 2-in-1 veneer peeling machines. With rising wages in manufacturing hubs and persistent skills shortages in technical trades, producers are turning to machines that require fewer operators and less specialized maintenance.

By 2026, user-friendly HMI (Human-Machine Interface) panels, augmented reality (AR)-assisted maintenance, and modular component designs will reduce training time and simplify repairs. Fully automated systems will cut labor needs by up to 60% compared to traditional mechanical peeling lines.

Moreover, the integration of digital twins—virtual replicas of physical machines—will allow operators to simulate setups, optimize parameters, and troubleshoot issues remotely, further reducing the need for on-site expertise.

This trend is particularly impactful in labor-constrained markets like Germany and Japan, as well as in developing regions where workforce training is a bottleneck to industrial scaling.

Conclusion

By 2026, the global 2-in-1 veneer peeling machine market will be defined by intelligent, efficient, and high-capacity systems that align with broader industrial and environmental goals. Automation, energy efficiency, high-speed production, and labor cost reduction are not isolated trends but interconnected forces driving innovation. Manufacturers who embrace these developments will gain a decisive edge in productivity, sustainability, and global competitiveness.

How to Evaluate a High-Quality 2-in-1 Veneer Peeling Machine

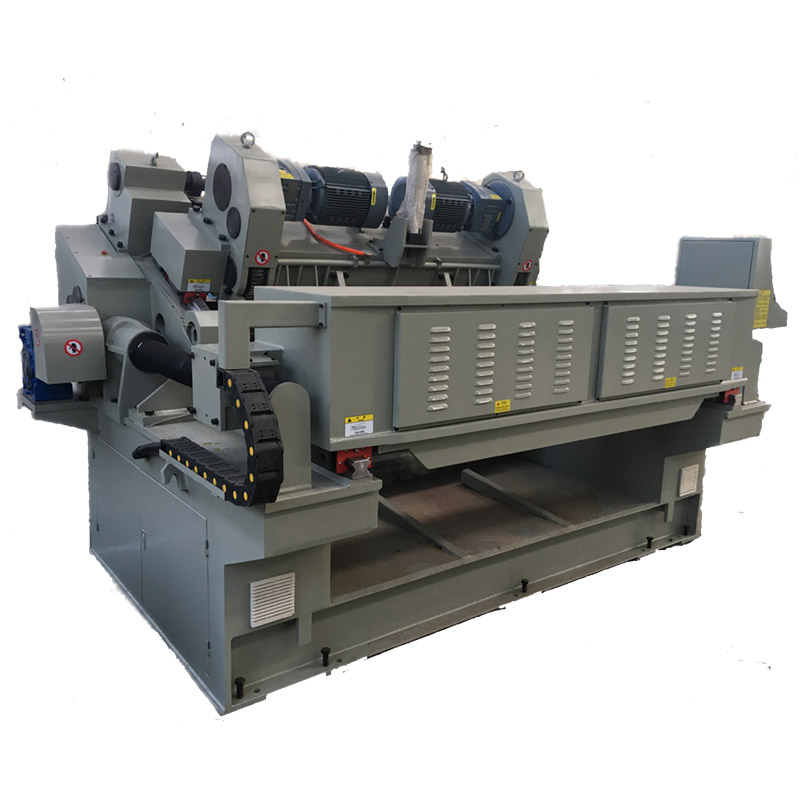

When selecting a high-quality 2-in-1 veneer peeling machine—designed to both slice and reconstitute veneer—several critical components determine its performance, longevity, and operational efficiency. Key evaluation points include the steel structure durability, motor brand, PLC control system, and spare parts availability. Assessing these factors ensures reliability and minimizes downtime in your production process.

Steel Structure Durability

The machine’s frame is the foundation of its stability and precision. A high-quality 2-in-1 veneer peeler should feature a robust, heavy-duty steel structure made from high-tensile, anti-corrosion materials (e.g., Q235 or Q345 steel). Look for fully welded construction with stress-relieved components to prevent deformation over time. A rigid frame minimizes vibration during high-speed operation, ensuring consistent veneer thickness and surface quality. Additionally, powder-coated or galvanized finishes enhance resistance to moisture and industrial wear, especially in humid wood processing environments.

Motor Brand (e.g., Siemens/Mitsubishi)

The drive motors power the peeling and feeding mechanisms, directly impacting cutting precision and machine lifespan. Reputable brands like Siemens, Mitsubishi, or ABB are indicators of high performance, energy efficiency, and long-term reliability. These motors offer superior torque control, smooth speed regulation, and excellent heat dissipation—critical for continuous operation. Verify that both the main spindle motor and feed motor are from globally recognized manufacturers, and check for IP ratings (e.g., IP55) ensuring dust and moisture resistance.

PLC Control System

A sophisticated PLC (Programmable Logic Controller) system is essential for automation, precision, and ease of operation. Top-tier machines use PLCs from trusted brands such as Siemens, Mitsubishi, or Omron. The system should offer user-friendly HMI (Human-Machine Interface) touchscreens for setting veneer thickness, monitoring machine status, and diagnosing faults. Advanced features like auto-calibration, data logging, and fault alarms improve productivity and reduce operator error. Ensure the PLC supports real-time adjustments and integrates seamlessly with other machine functions for synchronized operation.

Spare Parts Availability

Long-term machine uptime depends heavily on the availability of replacement parts. Choose a supplier or manufacturer with a strong global or regional service network. High-quality machines from established brands typically offer readily available spare parts—such as belts, bearings, cutting knives, sensors, and control modules—reducing downtime during maintenance or breakdowns. Confirm whether the manufacturer provides a detailed parts catalog, technical support, and a responsive after-sales service team. Machines with standardized components (e.g., ISO-compliant motors or bearings) are easier and more cost-effective to maintain.

By thoroughly evaluating these four critical aspects—steel structure durability, motor brand, PLC control system, and spare parts availability—you can confidently select a high-performance 2-in-1 veneer peeling machine that delivers precision, reliability, and long-term value.

Guide for Importing 2-in-1 Veneer Peeling Machines from China

Voltage Requirements (380V/220V)

When importing a 2-in-1 veneer peeling machine from China, it’s crucial to confirm the machine’s voltage compatibility with your local power supply. Most industrial machines manufactured in China operate on 380V, 3-phase, 50Hz, which is standard for Chinese factories. However, some suppliers may offer models compatible with 220V, single-phase power, typically for smaller or less powerful units.

- Verify Voltage Specifications: Always request detailed electrical specifications from the supplier before purchase. Confirm whether the machine requires 380V or 220V and whether it’s single-phase or three-phase.

- Transformer Needs: If your facility uses a different voltage (e.g., 480V/60Hz in North America), you may need a step-down transformer or a frequency converter, increasing setup costs.

- Customization Options: Many Chinese manufacturers can customize the motor and electrical components to match your country’s voltage standards—confirm this capability during negotiations.

Installation Support

Proper installation is essential for the safe and efficient operation of a 2-in-1 veneer peeling machine. Most Chinese suppliers offer varying levels of installation support:

- On-Site Installation Services: Some manufacturers provide technicians who can travel to your facility to oversee installation, conduct safety checks, and ensure proper setup. This service may incur additional fees for travel and labor.

- Remote Support: Many suppliers offer video calls, detailed manuals, and real-time guidance via platforms like Zoom or WhatsApp to assist with installation.

- Pre-Installation Requirements: Ensure your facility has a solid concrete foundation, adequate space, proper electrical connections, and safety clearances. Request a site preparation checklist from the supplier.

Warranty Terms

Warranty coverage varies significantly between Chinese manufacturers, so it’s vital to clarify terms before purchase:

- Standard Warranty Period: Most reputable suppliers offer a 12-month warranty on major components (motor, gearbox, frame) from the date of shipment.

- Coverage Details: Confirm what is included—typically mechanical parts and manufacturing defects. Wear-and-tear items (e.g., belts, bearings) and damage from improper use are usually excluded.

- After-Sales Service: Inquire whether warranty claims are handled locally (if the supplier has a regional office) or require returning parts to China. Some suppliers stock critical spare parts in international warehouses for faster service.

- Extended Warranty Options: Ask if extended warranty packages are available for an additional cost.

Spare Blade and Part Kits

Given the wear-prone nature of veneer peeling machines, having spare parts on hand minimizes downtime:

- Spare Blade Kits: Request a spare knife set (typically includes 2–4 blades) with your initial order. High-quality alloy blades are crucial for clean peeling and longevity.

- Recommended Spare Parts Kit: Consider ordering a comprehensive spare parts kit including:

- Additional cutting blades and blade holders

- Belts and pulleys

- Bearings and seals

- Electrical fuses and contactors

- Hydraulic hoses (if applicable)

- Availability and Lead Time: Confirm how quickly spare parts can be shipped from China and whether local distributors or third-party suppliers carry compatible components.

- Customization and Compatibility: Ensure that replacement blades match your machine’s specifications (length, thickness, mounting type) to avoid fitment issues.

By carefully addressing voltage compatibility, securing reliable installation support, understanding warranty limitations, and stocking essential spare parts, you can ensure a smooth and efficient integration of your imported 2-in-1 veneer peeling machine into your production line.

In conclusion, sourcing a 2-in-1 veneer peeling machine from China offers a cost-effective and efficient solution for enhancing plywood and veneer production capabilities. However, ensuring product quality and compliance is critical to long-term operational success. It is strongly recommended to verify that the machine comes with a valid CE certification, confirming it meets essential health, safety, and environmental protection standards within the European Economic Area. Additionally, arranging for pre-shipment inspection and testing of the machine—either through a trusted third-party inspector or by visiting the supplier’s facility—helps confirm that the equipment performs as specified and is free from defects. Taking these precautions minimizes risks, ensures reliability, and supports a successful investment in your manufacturing process.