الاستدامة

As a plywood machinery manufacturer, we believe that sustainability is our responsibility. We are committed to developing machines that support energy efficiency, resource optimization, and cleaner production in the wood industry.

Why Sustainability Matters in the Plywood Industry

Wood Is a Finite Resource

Growing Global Demand

High Material Waste

Energy-Intensive Production

Pollution Risks

Pressure from Regulations

Customer Expectations

Competitive Advantage

Waste Recovery Opportunities

Responsibility to Future Generations

Sustainability in Manufacturing

1. Eco-Friendly Material Selection

We choose high-strength, recyclable materials such as carbon steel, stainless steel, and aluminum to ensure durability and a long service life, reducing the need for frequent replacements.

For components like wire insulation and seals, we use degradable or recyclable materials, avoiding hard-to-decompose plastics such as PVC.

2. Energy-Efficient Production Processes

We adopt advanced equipment including CNC machining centers, laser cutting machines, and automated welding systems to achieve precise cutting, reduce material waste, and improve production efficiency.

Intelligent control systems help lower defect rates and minimize rework, further conserving energy and raw materials.

3. Waste and Byproduct Recycling

Metal scraps, leftover paint, and packaging materials are carefully sorted and recycled whenever possible.

Reusable materials are sent back for smelting or repurposing, minimizing landfill waste and environmental impact.

4. Low-Pollution Surface Treatment

We replace traditional high-pollution methods with eco-friendly coatings such as powder coating and low-VOC paints.

These treatments significantly reduce harmful gas emissions, protect worker health, and meet international environmental standards.

5. Durability and Modular Design

Our machines are built with long-lasting components and a modular structure, making them easy to maintain, repair, and upgrade.

This reduces full machine replacement, lowers material consumption, and supports long-term sustainable use.

Our Sustainability Efforts

Sally Pan

We are dedicated to building efficient, eco-friendly plywood machinery that supports sustainable practices and reduces environmental impact.

1.Reducing Wood Waste and Getting the Most from Materials

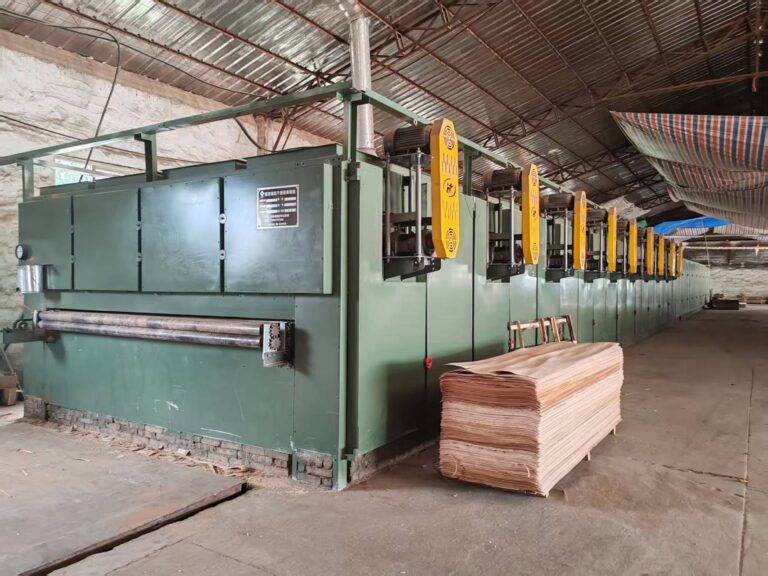

We help our customers cut down wood waste with smart machine designs and efficient solutions. Our rotary lathes make the leftover wood core very small—just 26mm—so less wood is wasted. Accurate veneer cutting and precise edge trimming make sure the wood pieces are the right size with clean edges, reducing material loss. Leftover wood scraps and trimmings can be reused as fuel for boilers or burners, turning waste into useful energy. We also offer machines that join small veneer pieces together to create bigger, usable sheets, and energy-saving drying systems that burn wood waste directly as fuel, helping save energy and materials.

2. Energy-Saving Solutions

We focus on using smart designs and advanced controls to help our customers save energy, cut costs, and make their production greener. Our dryers use efficient heat exchange systems to get the most heat from fuel, so less is wasted. Motors and fans have variable speed drives that adjust automatically to the work needed, saving electricity. Plus, our waste heat recovery systems capture leftover heat and reuse it, reducing energy use and pollution while improving overall efficiency.

3.Durability & Sustainable Manufacturing

Our machines are built with high-quality, durable parts to last longer and reduce the need for replacements, saving resources. Their modular design makes maintenance and repairs easier, so fewer machines are fully discarded. Plus, our dryers include effective dust and gas filters to cut pollution and protect the environment.

Guoyu's Sustinability Goals for 2050

المنتجات

Improving energy efficiency in our machines and manufacturing processes

كفاءة الطاقة

Supporting cleaner production with equipment that minimizes raw material loss and emissions

Supply chain

Working with partners to promote responsible use and environmental awareness

Resource Efficiency

Using more durable and recyclable materials to reduce waste over time

Extending machine lifespan

Extending machine lifespan through modular design and easy maintenance

Safety at Work

No serious accidents at work

مرحبًا، أنا لونا، مديرة المبيعات في Guoyu. يسعدني أنا وفريقي معرفة المزيد عن متطلباتك الخاصة ودعم إنتاجك من الخشب الرقائقي.

احصل على المزيد من المزايا بعد إرسال نموذج المعلومات

*نحن نحترم خصوصيتك وجميع المعلومات محمية.

احصل على المزيد من المزايا بعد إرسال نموذج المعلومات

أنا ليو، رئيس فريق المبيعات في E-abel. يسعدني أنا وفريقي أن نلتقي بك ونتعرف على كل ما يتعلق بعملك ومتطلباتك وتوقعاتك.

*نحن نحترم خصوصيتك وجميع المعلومات محمية.

أخبار الشركة

صناعة الخشب الرقائقي الأفريقي: مزايا التنمية والتحديات ومعدات الإنتاج الموصى بها

مزايا تطوير صناعة الخشب الرقائقي في البلدان الأفريقية 1. وفرة موارد الأخشاب 2. انخفاض تكاليف العمالة تتمتع أفريقيا بقوة عاملة شابة ووفيرة. الأجور

نصائح صيانة آلات تقشير القشرة الخشبية

الحفاظ على صيانة آلة تقشير القشرة بشكل جيد هو مفتاح التشغيل السلس والأداء طويل الأمد. يمكن أن تمنع العناية اليومية البسيطة - مثل التنظيف والتشحيم والفحوصات المنتظمة - حدوث المشاكل وتضمن

صناعة الخشب الرقائقي في فيتنام: المزايا والتحديات وكيف يمكننا دعم أعمالك - Linyi Guoyu Machinery Co.,Ltd

ما هي المواد الخام المستخدمة في صناعة الخشب الرقائقي الفيتنامي؟ يستخدم الخشب الرقائقي الفيتنامي بشكل أساسي خشب الأوكالبتوس كمواد أساسية. ينمو خشب الأوكالبتوس بسرعة (يكون جاهزًا للحصاد في غضون 5-7 سنوات،,

أفضل 3 شركات مصنعة لآلات تقشير القشرة الخشبية بدون عمود (مراجعة 2026)

في مجال معالجة الأخشاب المتطور، أصبحت آلات تقشير القشرة الخالية من المغزل ضرورية لتحقيق الدقة والكفاءة والإنتاج بكميات كبيرة. مع تزايد الطلب على

أفضل 3 شركات مصنعة لآلات التقشير الدوارة (مراجعة 2026)

في ظل المنافسة الشديدة في مجال آلات معالجة الأخشاب، يواصل مصنعو المخرطة الدوارة لتقشير الأخشاب وضع معايير جديدة في الكفاءة والمتانة والهندسة الدقيقة. مع تزايد الطلب

أفضل 4 مصنّعين لآلات صنفرة الخشب الرقائقي (مراجعة 2026)

في صناعة النجارة سريعة التطور، يعد اختيار ماكينة صنفرة الخشب الرقائقي المناسبة أمرًا بالغ الأهمية لتحقيق الدقة والكفاءة والمتانة طويلة الأمد في الإنتاج. مع تزايد الطلب العالمي على

أفضل 4 مصنعي آلات قطع الخشب الرقائقي (مراجعة 2026)

في قطاع آلات النجارة سريع التطور، يعد الحصول على مناشير قطع عرضية عالية الأداء للخشب الرقائقي أمرًا بالغ الأهمية لتحسين كفاءة الإنتاج وضمان المتانة على المدى الطويل. مع تزايد الطلب العالمي على