In the fast-evolving wood processing industry, debarker machines play a pivotal role in ensuring clean, efficient log preparation. As demand for high-performance equipment grows, manufacturers are prioritizing efficiency, durability, and precision engineering. China has emerged as a global hub for advanced woodworking machinery, combining innovative design with cost-effective production. This 2026 review highlights the top seven debarker machine manufacturers renowned for robust build quality, operational reliability, and proven performance in demanding industrial environments—helping sourcing professionals make informed procurement decisions in a competitive market.

Top 7 Debarker Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Log Debarker Machine Manufacturers and Factory

Official Website: fandapelletmill.com

Fanda Machinery is one of the leading China log debarker machine manufacturers, providing the best quality equipment with competitive price….

#2 8 feet log debarker from China Manufacturers

Official Website: peeling-machine.goldsupplier.com

Explore 8 feet log debarker products at Shandong Jinlun Machinery Manufacturing Co., Ltd., reliable China manufacturer. Contact us for more details!…

#3 Debarker Manufacturer

Official Website: iem.ca

IEM manufacturers the best low maintenance, heavy duty, high capacity industrial debarkers. We manufacture debarkers for Sawmills, Pulp & Paper Mills, ……

#4 China Log Debarking Machine Manufacturers Suppliers Factory

Official Website: logpeeling.com

YIHONG is one of the most professional log debarking machine manufacturers and suppliers in China. Please feel free to buy used log debarking machine for ……

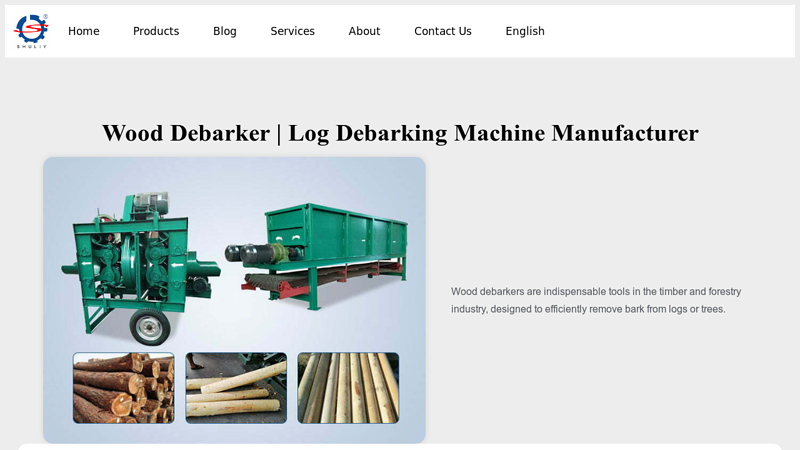

#5 Wood Debarker Log Debarking Machine Manufacturer Price

Official Website: woodmachine.org

Wood debarking machine can handle various types and sizes of wood. With its high debarking rate, it can quickly and effectively remove the bark, ……

#6 Debarker Machine for Manufacturing Wood Log Veneer from China …

Official Website: yuequnmachinery.com

Rating 5.0 (46) Debarker Machine for Manufacturing Wood Log Veneer · 1. Easy to operate and high production efficiency. Enlarged double roller and single roller. · 2. Reliable ……

#7 Nicholson Manufacturing

Official Website: debarking.com

Nicholson is committed to continually developing and building the world’s finest ring debarkers. Our teams of research and development engineers work closely ……

Professional Buying Guide: Debarker Machinery

2026 Global Debarker Market Trends: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global debarker market is undergoing a significant transformation driven by increasing industrial demands, technological advancements, and economic pressures. By 2026, key trends will center around automation, energy efficiency, high-speed production, and labor cost reduction, reshaping equipment design, operational strategies, and market competitiveness.

Automation Integration Driving Operational Efficiency

By 2026, automation will be a cornerstone of advanced debarking systems. Fully automated debarkers integrated with Industry 4.0 technologies—such as IoT sensors, AI-driven analytics, and machine vision systems—will dominate high-volume operations. These systems enable real-time monitoring of bark removal efficiency, predictive maintenance, and adaptive control based on log diameter, species, and moisture content. Automated feeding and sorting lines will minimize human intervention, enhancing process consistency and reducing downtime. The integration of robotics for log handling and post-debarking inspection will further streamline operations, particularly in sawmills and biomass processing plants aiming for end-to-end digitalization.

Energy Efficiency as a Core Design and Operational Priority

With rising energy costs and stricter environmental regulations, energy efficiency will be a decisive factor in debarker selection and operation. Manufacturers will focus on developing hydraulic and mechanical systems with optimized power transmission, variable frequency drives (VFDs), and regenerative braking mechanisms to reduce electricity consumption. Innovations such as low-friction drum designs, efficient motor configurations, and smart load-sensing hydraulics will become standard. Additionally, companies will increasingly adopt renewable energy sources to power debarking operations, aligning with corporate sustainability goals and reducing carbon footprints across the wood processing value chain.

High-Speed Production to Meet Growing Demand

Global demand for lumber, pulp, and bioenergy will continue to drive the need for high-speed debarking solutions. By 2026, debarkers capable of processing over 300 logs per hour with consistent quality will gain market share, especially in large-scale operations in North America, Northern Europe, and emerging markets in Southeast Asia. High-speed rotary and ring-type debarkers will be equipped with advanced rotor dynamics and improved knife configurations to maintain surface quality at accelerated throughput rates. The ability to handle diverse log sizes and species without frequent changeovers will further enhance production flexibility and uptime, supporting just-in-time manufacturing models.

Labor Cost Reduction Through Technological Advancements

Labor scarcity and rising wages, particularly in developed economies, will accelerate the shift toward labor-minimized debarking systems. Automated and remotely monitored debarkers will significantly reduce the need for on-site operators, lowering both direct labor costs and expenses related to training, safety, and turnover. User-friendly Human-Machine Interfaces (HMIs) and centralized control systems will allow single operators to manage multiple machines, improving labor productivity. Furthermore, reduced manual handling will enhance workplace safety, decreasing accident-related costs and insurance premiums. This trend will be especially pronounced in regions facing demographic challenges and tightening labor markets.

In conclusion, the 2026 global debarker market will be defined by intelligent, energy-conscious, and high-throughput systems designed to maximize efficiency while minimizing operational costs. Manufacturers and operators who embrace automation, energy optimization, speed, and labor reduction will gain a decisive competitive advantage in an increasingly automated and sustainable industrial landscape.

Key Check Points for Evaluating a High-Quality Debarker

When selecting a high-quality debarker for industrial applications, several critical components determine long-term performance, reliability, and operational efficiency. Below are the essential evaluation points to consider:

Steel Structure Durability

The robustness of the debarker’s steel frame directly impacts its lifespan and resistance to heavy operational stress. Look for:

- High-Tensile Steel Construction: Frames made from reinforced, high-grade steel (e.g., Q345 or equivalent) ensure stability under continuous load.

- Anti-Corrosion Treatment: Powder-coated or hot-dip galvanized surfaces protect against moisture and rust, especially in wet or outdoor environments.

- Rigid Welded Design: A fully welded, box-type frame minimizes vibration and deformation during operation, enhancing machine longevity.

Motor Brand and Performance (e.g., Siemens, Mitsubishi)

The motor drives the debarking mechanism and must deliver consistent, high-torque performance. Evaluate based on:

- Reputable Brand Usage: Motors from globally recognized brands like Siemens, Mitsubishi, or ABB offer proven reliability, energy efficiency, and thermal protection.

- Power Match & Duty Rating: Ensure the motor is appropriately sized (kW/HP) for the log diameter and feed rate, with a continuous duty rating (S1) suitable for 24/7 operation.

- Inverter Compatibility: High-quality motors should support variable frequency drives (VFDs) for speed control and soft starts, reducing mechanical stress.

PLC Control System

An advanced PLC ensures precise control, automation, and system diagnostics. Key factors include:

- Trusted PLC Manufacturers: Systems using Siemens, Mitsubishi, or Omron PLCs provide stable, programmable logic with user-friendly HMI interfaces.

- Automation Features: Look for auto-feed control, overload protection, fault diagnostics, and adjustable debarking intensity settings.

- Remote Monitoring & Data Logging: Modern PLCs offer connectivity (e.g., Ethernet/IP, Modbus) for remote troubleshooting and performance tracking.

Spare Parts Availability

Minimizing downtime is crucial—readily available spare parts ensure quick repairs and sustained operation.

- Global or Local Support Network: Choose suppliers with established service centers and inventory in your region.

- Standardized Components: Machines using common, off-the-shelf parts (e.g., bearings, seals, chains) reduce replacement lead times.

- Supplier Commitment: Verify the manufacturer offers long-term parts supply (10+ years) and provides a detailed spare parts list with the machine.

By thoroughly assessing these four key areas—steel structure durability, motor brand, PLC control system, and spare parts availability—you can confidently select a high-quality debarker that delivers reliable, efficient performance over its operational life.

Guide for Importing a Debarker from China: Key Considerations

Voltage Requirements (380V/220V)

When importing a debarker from China, it’s crucial to confirm the machine’s electrical specifications match your local power supply. Most industrial machinery manufactured in China operates on 380V, 3-phase, 50Hz, which is standard across Chinese factories. However, some smaller or customized models may be available in 220V, single-phase configurations.

- Verify Voltage Compatibility: Ensure your facility can support 380V 3-phase power. If your location uses 480V or 415V systems (common in North America or Europe), you may need a step-down transformer or a custom-built machine.

- Request Electrical Drawings: Ask the supplier for detailed electrical schematics and motor specifications before finalizing the order.

- Custom Voltage Options: Reputable manufacturers can often customize the motor and control panel to meet your voltage needs—confirm this capability and any added cost or lead time.

Installation Support

Proper installation is key to optimal debarker performance and safety. Evaluate the level of support offered by the Chinese supplier:

- On-Site Technical Assistance: Some suppliers offer technician派遣 (dispatch) services for on-site installation, commissioning, and operator training—often for an additional fee. Clarify travel costs, duration, and language support (preferably English-speaking technicians).

- Remote Guidance: If on-site support isn’t feasible, ensure the supplier provides comprehensive installation manuals, video tutorials, and remote troubleshooting via phone or video call.

- Foundation and Setup Requirements: Confirm if the supplier provides specifications for foundation preparation, material feed systems, and utility connections (power, air, water).

Warranty Terms

Warranty coverage varies significantly among Chinese manufacturers. Carefully review the terms before purchase:

- Standard Warranty Period: Most offer a 12-month warranty on main components (motor, gearbox, frame), but exclude wear items like blades, bearings, and belts.

- Coverage Details: Warranty typically covers manufacturing defects, not damage due to improper use, lack of maintenance, or incorrect installation.

- Service and Repairs: Clarify how warranty claims are handled—whether parts are shipped free of charge, if technical support is included, and who covers shipping costs (usually split or paid by buyer).

- Extended Warranty Options: Some suppliers offer extended warranties for 2–3 years—consider this for critical production equipment.

Spare Blade and Part Kits

Due to shipping delays and customs processing, having spare parts on hand is essential for minimizing downtime:

- Spare Blade Kits: Request a starter kit including extra debarking blades (typically made of high-strength alloy steel), blade holders, and adjustment tools. Blades are wear items and may need replacement every few weeks to months depending on usage.

- Comprehensive Spare Parts Package: Consider ordering a full maintenance kit with commonly replaced components such as belts, bearings, seals, hydraulic hoses (if applicable), and fuses.

- Long-Term Availability: Confirm the supplier can provide spare parts for at least 5–7 years post-purchase. Request a detailed parts list with OEM or equivalent part numbers.

- Inventory Planning: Based on expected usage, calculate spare part consumption and maintain a 6–12 month supply locally.

By addressing voltage compatibility, securing reliable installation support, understanding warranty limitations, and stocking essential spare parts, you can ensure a smooth integration of your imported debarker into your operations.

In conclusion, sourcing a debarker machine from China can offer significant cost advantages and access to advanced manufacturing capabilities. However, ensuring the quality, safety, and reliability of the equipment is paramount. It is essential to verify that the machine complies with international standards by confirming the presence of a valid CE certification, which indicates adherence to European health, safety, and environmental protection requirements. Additionally, arranging for pre-shipment inspection and functional testing of the debarker machine is crucial to ensure it performs as specified and meets your operational needs. Taking these precautions minimizes risks, avoids potential delays or failures upon arrival, and supports a successful and efficient procurement process. By prioritizing certification and thorough testing, buyers can confidently invest in high-quality machinery that delivers long-term value and performance.