As demand for high-performance debarking solutions rises across the global wood processing industry, sourcing partners are increasingly focused on efficiency, durability, and cost-effective manufacturing. In 2026, Chinese manufacturers continue to lead the market, combining advanced engineering with scalable production to deliver reliable machinery that meets rigorous industrial standards. This review highlights the top five debarking machine manufacturers renowned for innovation, robust build quality, and proven performance in diverse timber-processing environments.

Top 5 Debarking Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Wood Debarking Machine Manufacturers and Factory

Official Website: fandapelletmill.com

Fanda Machinery is one of the leading China wood debarking machine manufacturers, providing the best quality equipment with competitive price….

#2 China Log Debarking Machine Manufacturers Suppliers Factory

Official Website: logpeeling.com

YIHONG is one of the most professional log debarking machine manufacturers and suppliers in China. Please feel free to buy used log debarking machine for ……

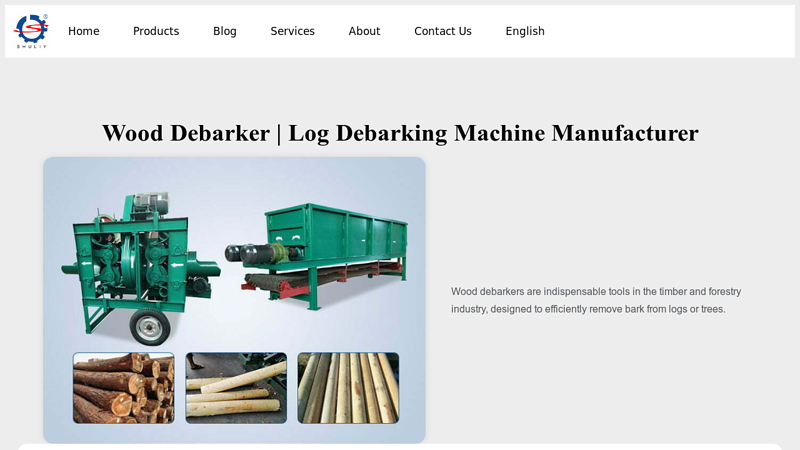

#3 Wood Debarker Log Debarking Machine Manufacturer Price

Official Website: woodmachine.org

Wood debarking machine can handle various types and sizes of wood. With its high debarking rate, it can quickly and effectively remove the bark, ……

#4 Morbark

Official Website: morbark.com

Morbark tree care equipment minimizes wood waste, lowering transport costs and creating valuable recycled products like chips, fuel, and compost additives….

#5 Nicholson Manufacturing

Official Website: debarking.com

Nicholson is committed to continually developing and building the world’s finest ring debarkers. Our teams of research and development engineers work closely ……

Professional Buying Guide: Debarking Machinery

2026 Global Debarking Market Trends: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

Automation in Debarking Systems

By 2026, automation is expected to be a dominant force reshaping the global debarking industry. Advances in robotics, artificial intelligence (AI), and machine vision are enabling fully automated debarking lines that can adapt to variable log sizes, species, and surface conditions with minimal human intervention. Integrated sensor technologies—such as LiDAR and infrared imaging—allow real-time log profiling, optimizing the debarking process for maximum efficiency and wood recovery.

Automated controls and predictive maintenance systems, powered by Industrial Internet of Things (IIoT) platforms, are increasingly deployed to reduce downtime and improve operational consistency. Major equipment manufacturers are incorporating modular automation packages that can be retrofitted into existing mills, accelerating adoption across both greenfield and brownfield sites. In regions like North America and Northern Europe, where skilled labor is scarce, automation is becoming a strategic necessity rather than an option.

Energy Efficiency as a Competitive Advantage

Energy efficiency is emerging as a critical differentiator in the 2026 debarking landscape, driven by rising energy costs and tightening environmental regulations. Modern debarking systems are being engineered to reduce power consumption per cubic meter of processed wood. Innovations such as variable frequency drives (VFDs), optimized drum rotation speeds, and low-friction roller designs contribute to significant energy savings.

Additionally, closed-loop water recycling systems minimize both water and energy use by reducing the need for pumping and heating. In Scandinavia and Central Europe, where sustainability benchmarks are strict, energy-efficient debarking units are often required for compliance with carbon reporting standards such as EU ETS (Emissions Trading System). Manufacturers investing in energy-smart technologies are gaining market share, particularly in eco-certified supply chains like FSC and PEFC.

High-Speed Production to Meet Growing Demand

Global demand for wood fiber—driven by pulp, paper, engineered wood, and bioenergy sectors—is pushing mills to adopt high-speed debarking solutions. By 2026, next-generation debarkers are capable of processing logs at rates exceeding 300 m³/hour, with precision and consistency maintained through dynamic control algorithms.

High-speed rotary and ring debarkers are being redesigned with reinforced materials and improved wear resistance to withstand continuous operation. Parallel advancements in log infeed systems—such as automated sorting and alignment—ensure a steady flow of material into the debarking zone, minimizing bottlenecks. These enhancements are particularly valuable in large-scale operations in Brazil, Russia, and Canada, where economies of scale depend on throughput maximization.

Labor Cost Reduction Through Technological Integration

Labor cost reduction remains a key driver behind technological investment in debarking. With rising wages and chronic labor shortages in the forestry and wood processing sectors, companies are turning to integrated solutions that minimize manual handling and supervision. Fully automated debarking lines can reduce direct labor needs by up to 60–70% compared to conventional setups.

Remote monitoring and centralized control rooms allow operators to oversee multiple processes from a single interface, increasing productivity per employee. Furthermore, the integration of digital twins and augmented reality (AR) enables remote diagnostics and training, cutting down on onsite technical staffing requirements. This trend is especially pronounced in developed markets such as the U.S., Germany, and Japan, where labor costs are highest.

In emerging markets, while labor remains relatively inexpensive, the push for export-oriented, high-quality production is also encouraging investment in labor-saving technologies to improve consistency and meet international standards.

In conclusion, the 2026 global debarking market is being transformed by a convergence of automation, energy efficiency, high-speed capabilities, and labor optimization. Companies that embrace these trends are poised to achieve greater operational resilience, lower costs, and improved sustainability—key advantages in an increasingly competitive and regulated industry.

Key Checkpoints for Evaluating a High-Quality Debarking Machine

When assessing the quality and reliability of a debarking machine, several critical factors must be examined to ensure long-term performance, efficiency, and minimal downtime. Below are the essential evaluation points:

Steel Structure Durability

The steel frame and overall structural integrity of the debarking machine are fundamental to its longevity and resistance to heavy operational stress. Look for:

– Use of high-tensile, corrosion-resistant steel (e.g., Q345 or equivalent)

– Reinforced welding techniques and stress-relieved construction to prevent deformation

– Protective coatings or treatments (e.g., sandblasting and anti-rust paint) for harsh environments

– Rigid base design that minimizes vibration and ensures stability during operation

A robust steel structure directly impacts machine lifespan and maintenance frequency.

Motor Brand and Performance

The motor drives the debarking drum or blades and significantly influences efficiency and reliability. Key considerations include:

– Preference for internationally recognized brands such as Siemens, Mitsubishi, ABB, or WEG

– Appropriate power rating (kW) matched to the machine’s capacity and log size range

– IP rating (e.g., IP55 or higher) for dust and moisture resistance

– Energy efficiency (IE3 or IE4 standard) for reduced operating costs

High-quality motors ensure consistent performance, lower failure rates, and better energy use.

PLC Control System

Modern debarking machines rely on automation for precision and ease of operation. The PLC (Programmable Logic Controller) system should offer:

– Reputable brands like Siemens, Mitsubishi, or Omron for reliability and support

– User-friendly HMI (Human-Machine Interface) for monitoring and adjusting parameters (e.g., rotation speed, feeding rate)

– Fault diagnostics and alarm systems to reduce downtime

– Programmable settings for different log diameters and species

A sophisticated PLC system enhances operational control, improves safety, and simplifies maintenance.

Spare Parts Availability

Timely access to spare parts is crucial to minimizing unplanned downtime. Evaluate:

– Manufacturer’s inventory and global distribution network for critical components (e.g., blades, bearings, belts)

– Standardization of parts to allow sourcing from multiple suppliers if needed

– Documentation (manuals, part numbers, diagrams) provided with the machine

– Local service support or partnerships in your region

Machines from reputable brands with strong after-sales networks typically offer better spare parts availability and technical support.

By thoroughly assessing these four checkpoints—Steel Structure Durability, Motor Brand, PLC Control System, and Spare Parts Availability—you can confidently select a high-quality debarking machine that delivers reliable, efficient, and cost-effective performance over its operational life.

Importing Debarking Equipment from China: Key Considerations

When importing debarking machinery from China, it’s essential to address several critical factors to ensure smooth operation, longevity, and compliance with local standards. Below are important guidelines covering voltage requirements, installation support, warranty terms, and spare parts availability.

Voltage Requirements (380V/220V)

Electrical compatibility is crucial for the safe and efficient operation of industrial debarking equipment. Chinese manufacturers typically produce machinery designed for 380V three-phase power, which is standard in industrial settings across China. However, your local voltage standards may differ.

- Verify Local Power Supply: Confirm whether your facility operates on 380V or 220V three-phase voltage. While 380V is common for heavy-duty equipment, some regions use 400V or 415V—ensure compatibility.

- Request Custom Electrical Configuration: Specify your required voltage (e.g., 380V/50Hz or 220V/60Hz) when placing the order. Reputable suppliers can modify motors and control panels to meet your specifications.

- Include Transformers if Necessary: If your site only supports 220V, discuss the need for step-up transformers. Confirm whether the supplier can provide or recommend suitable transformers.

- Ensure Compliance with Local Electrical Codes: Confirm that the machine’s electrical design meets safety and regulatory standards in your country (e.g., CE, UL, or local certifications).

Installation Support

Proper installation is vital to ensure the machine functions correctly and safely. Clarify the level of support the Chinese supplier offers.

- On-Site Installation Services: Inquire if the supplier provides technicians for on-site installation and setup. This may involve additional costs and travel logistics, but it ensures correct assembly and calibration.

- Remote Support Options: If on-site support isn’t feasible, confirm availability of remote assistance via video calls, detailed manuals, or augmented reality tools.

- Pre-Installation Documentation: Request comprehensive installation manuals, wiring diagrams, and foundation requirements in advance to prepare your facility.

- Training for Operators and Maintenance Staff: Ensure the supplier offers operational training, either in person or online, to reduce downtime and prevent misuse.

Warranty Terms

Understanding the warranty coverage helps protect your investment and ensures accountability.

- Standard Warranty Period: Most Chinese manufacturers offer a 12-month warranty on parts and labor. Confirm the duration and what components are covered (e.g., motors, gearboxes, hydraulic systems).

- Exclusions and Limitations: Review what is not covered—typically wear items like blades, belts, and bearings unless defective. Also, damage from improper use, incorrect voltage, or lack of maintenance is usually excluded.

- Warranty Claim Process: Clarify the procedure for filing claims, including required documentation, response time, and whether parts will be shipped free of charge.

- Extended Warranty Options: Ask if extended warranty packages are available for an additional fee, especially for critical components.

Spare Blade and Replacement Parts Kits

Having easy access to spare parts minimizes downtime and extends machine life.

- Availability of Spare Blade Kits: Confirm that the supplier provides spare blade sets designed specifically for your model. Blades are consumables and should be replaced regularly.

- Comprehensive Spare Parts Kits: Consider ordering a starter kit that includes high-wear components such as belts, bearings, seals, and fasteners.

- Lead Time and Shipping Costs: Inquire about typical lead times for spare parts and whether they are kept in stock. Discuss options for local warehousing or regional distributors to reduce delays.

- Parts Compatibility and Labeling: Ensure all spare parts are clearly labeled and compatible with your machine’s model and serial number. Request a detailed parts list with diagrams.

By addressing these key areas before importing, you can ensure a smoother integration of debarking equipment into your operations, reduce unexpected costs, and maximize uptime and productivity. Always communicate clearly with your supplier and document all agreements in writing.

In conclusion, sourcing a debarking machine from China can offer significant cost advantages and access to advanced manufacturing capabilities. However, to ensure reliability, safety, and compliance with international standards, it is crucial to verify that the machine carries valid CE certification. This certification confirms that the equipment meets essential health, safety, and environmental protection requirements within the European Economic Area and is a strong indicator of overall quality. Additionally, it is highly recommended to conduct thorough on-site testing of the machine before shipment to assess its performance, durability, and operational efficiency under real-world conditions. By prioritizing CE certification and pre-shipment testing, buyers can mitigate risks, avoid costly delays or rework, and ensure the acquisition of a high-performing, compliant debarking machine that meets their operational needs.