In the fast-evolving plywood manufacturing sector, sourcing the right machinery is critical to ensuring operational efficiency, long-term durability, and cost-effective production. As global demand rises, Chinese manufacturers continue to set benchmarks in innovation, scalability, and technical expertise—delivering advanced solutions that power high-performance production lines. This 2026 review highlights the top nine plywood manufacturing machine manufacturers renowned for their engineering excellence, reliability, and strong alignment with modern industry needs.

Los 9 principales fabricantes de máquinas para el proceso de fabricación de madera contrachapada (revisión de 2026)

(Clasificados por capacidad técnica y reputación en el mercado)

#1 The thebault group

Sitio web oficial: groupe-thebault.com

A family-owned industrial group, the THEBAULT Group is a manufacturer of plywood made from Maritime Pine, Poplar or Okoume….

#2 Raute

Fundada: 1908

Sitio web oficial: raute.com

Desde 1908, las empresas han confiado en Raute para suministrarles maquinaria transformadora y servicios tecnológicos...

#3 The Plywood Manufacturing Process At ADX

Sitio web oficial: adxplywood.com

At ADX, we specialize in three primary types of plywood: veneer plywood, melamine plywood, and film-faced plywood. ADX Plywood is one of the top ……

#4 Plywood Production Proces

Sitio web oficial: contrachapado.com

El procesamiento hidrotérmico se lleva a cabo en piscinas de remojo llenas de agua a una temperatura de entre 40 y 60 °C, dependiendo de la especie de madera...

#5 Manufacturing Process Of Commercial Plywood

Sitio web oficial: ttplywood.com

At TT PLYWOOD, we take pride in our meticulous manufacturing process for commercial plywood. Each step is carefully executed to ensure the production of ……

#6 Homasote Company History and Manufacturing Process

Sitio web oficial: homasote.com

The unique Homasote manufacturing process begins when tons of post-consumer paper and newspaper are delivered to our plant and pulping employees….

#7 Columbia Forest Products

Sitio web oficial: columbiaforestproducts.com

Discover Columbia Forest Products, North America’s largest manufacturer of sustainable, decorative hardwood plywood and veneers for residential and ……

#8 Compra madera contrachapada al por mayor directamente del fabricante

Sitio web oficial: plyterra.com

Plyterra es un fabricante de madera contrachapada de confianza con más de 20 años de experiencia. Ofrece una amplia gama de calidades y tipos de madera contrachapada para compradores mayoristas...

#9 How is Plywood Made? A Veneer Mill Tour

Sitio web oficial: rayonier.com

To make plywood, a tree has to be debarked, steamed in a vault and then peeled into a long, thin sheet at the veneer mill. Those sheets are ……

Professional Buying Guide: Plywood Manufacturing Process Machinery

2026 Global Market Trends in Plywood Manufacturing Process: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global plywood manufacturing industry is undergoing a significant transformation as it heads toward 2026, driven by technological innovation, sustainability imperatives, and economic pressures. Key trends shaping the sector include increased automation, improved energy efficiency, high-speed production techniques, and strategic labor cost reduction. These developments are not only enhancing operational competitiveness but are also aligning the industry with global environmental and economic challenges.

Automatización en la fabricación de madera contrachapada

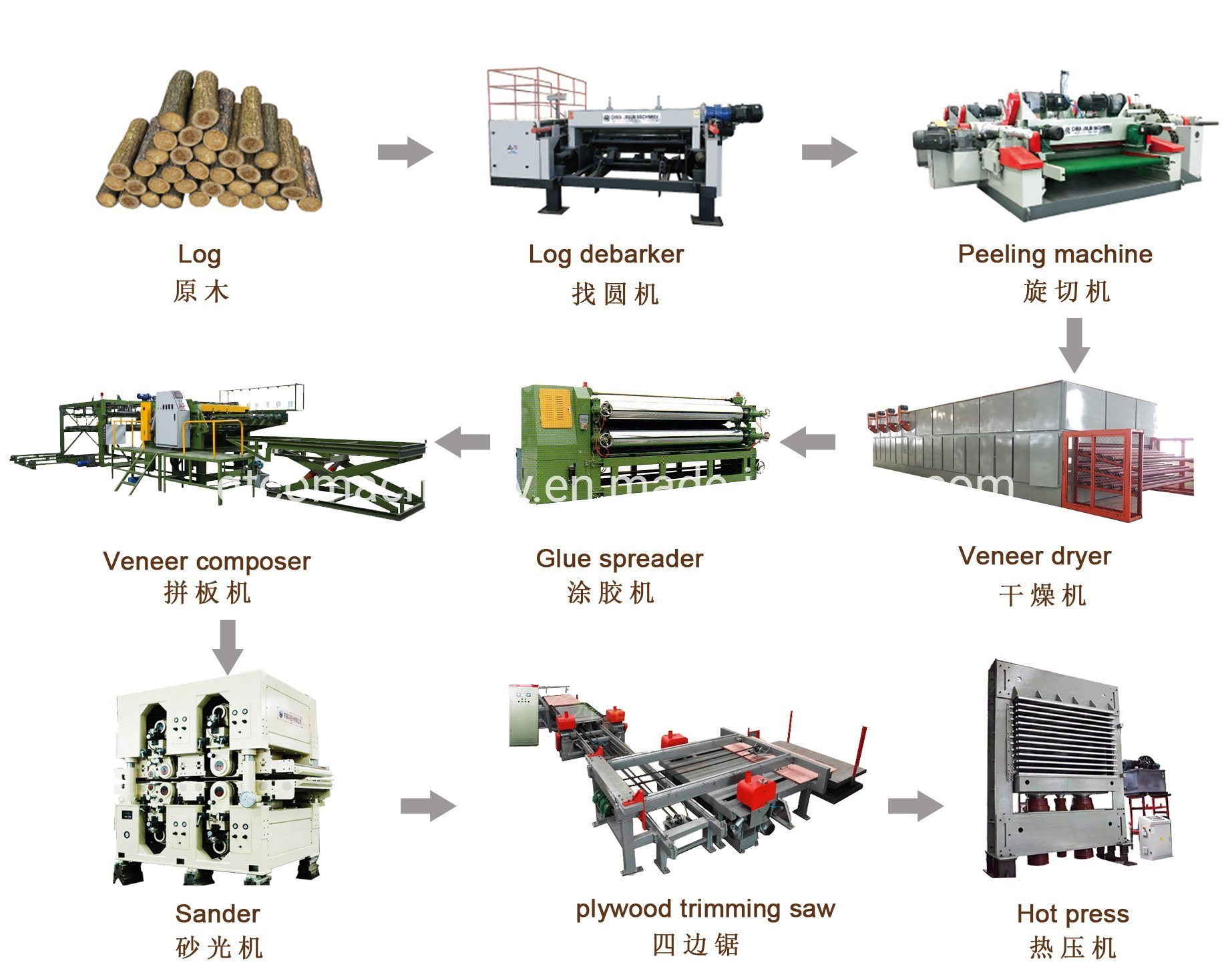

Automation is rapidly becoming a cornerstone of modern plywood production. By 2026, fully integrated automated systems are expected to dominate new and upgraded manufacturing facilities, particularly in North America, Europe, and parts of East Asia. Automated processes now span from log handling and veneer peeling to glue application, pressing, trimming, and quality inspection.

Robotic arms and AI-driven vision systems are increasingly deployed for real-time defect detection and sorting, reducing material waste and ensuring consistent product quality. Automated glue spreaders and stackers have minimized human intervention in high-risk areas, improving safety and throughput. Furthermore, the rise of Industry 4.0 technologies—such as IoT-enabled sensors and digital twins—allows for predictive maintenance and real-time monitoring of production lines, minimizing downtime.

The adoption of automation is especially critical in response to tightening labor markets and rising operational costs. As manufacturers scale automated systems, they achieve greater precision and consistency, which is essential for meeting the growing demand for high-grade plywood in construction and furniture industries.

Energy Efficiency as a Strategic Priority

Energy efficiency has emerged as a central concern for plywood manufacturers aiming to reduce carbon footprints and comply with stricter environmental regulations. The pressing and drying stages of plywood production are particularly energy-intensive, accounting for up to 70% of total energy consumption in a typical plant.

By 2026, a majority of leading manufacturers are expected to have transitioned to energy-efficient thermal systems, including biomass boilers, heat recovery units, and advanced kiln drying technologies. Biomass energy—derived from wood waste and by-products—is increasingly used to power operations, reducing reliance on fossil fuels and lowering greenhouse gas emissions.

Innovations such as infrared drying and vacuum pressing are being piloted to cut energy use and processing time. Additionally, smart energy management systems are being implemented to optimize power consumption across shifts and production lines. These advancements not only improve sustainability but also reduce long-term operational costs, providing a competitive edge in environmentally conscious markets.

High-Speed Production Techniques

To meet rising global demand—fueled by urbanization in Asia, Africa, and Latin America—plywood producers are investing heavily in high-speed production technologies. By 2026, continuous press lines (CPL) and rotary presses are expected to gain wider adoption, enabling uninterrupted production at speeds exceeding 100 meters per minute.

High-speed systems integrate advanced material handling, rapid-curing adhesives, and precision control mechanisms to maintain quality at elevated throughput rates. These technologies reduce cycle times and increase yield per unit of input, allowing manufacturers to scale output without proportional increases in capital or floor space.

Moreover, the integration of high-speed production with digital process control allows for real-time adjustments in veneer thickness, glue spread rate, and press pressure, ensuring optimal product performance. This flexibility is especially valuable in producing customized plywood for niche applications in modular construction and engineered wood products.

Reducción de los costes laborales mediante la integración tecnológica

Labor costs remain a significant operational expense in the plywood industry, particularly in emerging economies where wage inflation is accelerating. To counter this, manufacturers are adopting strategies that reduce dependency on manual labor through technological integration.

By 2026, semi-automated and fully automated plants will require up to 40% fewer operators compared to traditional setups. Tasks such as stacking, sorting, and packaging—once labor-intensive—are now handled by robotic systems. Remote monitoring and centralized control rooms allow fewer supervisors to manage larger production units.

While initial capital investment in automation is high, the long-term return on investment (ROI) is compelling due to reduced payroll expenses, lower error rates, and minimized workplace injuries. Additionally, manufacturers are investing in upskilling programs to transition workers into technical and supervisory roles, ensuring workforce alignment with new technologies.

Conclusión

The 2026 outlook for the global plywood manufacturing process is characterized by a convergence of automation, energy efficiency, high-speed production, and labor cost optimization. These trends are not isolated developments but interconnected drivers of a more agile, sustainable, and competitive industry. Companies that proactively invest in these areas are likely to lead market innovation, improve profitability, and meet evolving regulatory and consumer expectations. As the sector continues to modernize, the plywood industry will play a pivotal role in the broader transformation of the global wood products market.

Key Checkpoints for Evaluating a High-Quality Plywood Manufacturing Process

When assessing the quality and reliability of a plywood manufacturing process, several critical components directly influence productivity, uptime, and long-term performance. The following checkpoints should be thoroughly evaluated:

Durabilidad de las estructuras de acero

The structural integrity of the manufacturing equipment is foundational. A robust steel frame ensures stability during high-pressure pressing and continuous operation. Look for:

– Use of high-tensile, corrosion-resistant steel (e.g., Q345 or equivalent).

– Reinforced welding joints and stress-tested frame design.

– Anti-rust treatment such as hot-dip galvanization or powder coating.

– Equipment mounted on stable, vibration-dampening foundations.

A durable steel structure minimizes misalignment, reduces maintenance needs, and extends the machine’s service life—critical for consistent plywood quality.

Marca y rendimiento del motor (por ejemplo, Siemens, Mitsubishi)

The motors drive essential functions such as hot press movement, conveyor systems, and glue spreaders. Reputable motor brands ensure efficiency and reliability:

– Preference for globally recognized brands like Siemens, Mitsubishi, ABB, or SEW.

– Motors rated for continuous industrial use with IP55 or higher protection.

– Variable frequency drives (VFDs) for precise speed control and energy efficiency.

– Low noise, minimal heat generation, and high torque output.

High-quality motors reduce downtime, lower energy consumption, and support smooth integration with automation systems.

Sistema de control PLC

The PLC (Programmable Logic Controller) is the brain of the automated plywood line. A sophisticated control system enhances precision and operational ease:

– Use of established PLC brands such as Siemens S7 series, Mitsubishi FX/Q series, or Allen-Bradley.

– Touchscreen HMI (Human-Machine Interface) for intuitive monitoring and adjustments.

– Real-time diagnostics, fault logging, and remote access capability.

– Pre-set programs for different plywood thicknesses, lay-up patterns, and press cycles.

A reliable PLC system improves process consistency, reduces operator error, and enables seamless production scaling.

Disponibilidad de repuestos

Long-term operational efficiency depends on quick access to replacement components:

– Manufacturer or supplier must offer a comprehensive spare parts catalog.

– Critical components (seals, sensors, heating elements, hydraulic valves) should be readily available locally or through fast international shipping.

– Technical documentation and part numbering should be clear and standardized.

– Availability of local service support or authorized distributors.

Prompt spare parts availability minimizes downtime during breakdowns and ensures sustained production throughput.

Evaluating these four checkpoints—steel structure durability, motor brand quality, advanced PLC control, and spare parts accessibility—provides a comprehensive assessment of a high-quality plywood manufacturing process. Prioritizing these factors ensures reliability, efficiency, and long-term return on investment.

Guide for Importing Plywood Manufacturing Equipment from China: Key Considerations

When importing plywood manufacturing machinery from China, it’s vital to address several critical technical and support factors to ensure smooth integration and operation. This guide outlines key aspects including voltage compatibility, installation assistance, warranty coverage, and spare parts availability.

Requisitos de voltaje (380 V/220 V)

Most industrial plywood manufacturing equipment manufactured in China operates on a standard three-phase electrical supply of 380 V a 50 Hz. This is consistent with China’s industrial power infrastructure. However, some smaller machines or auxiliary units may use Alimentación monofásica de 220 V. Before finalizing your purchase, confirm the exact voltage and phase requirements of the equipment with the supplier. Ensure your facility’s electrical system matches these specifications or budget for transformer installations if converting from a different voltage (e.g., 480V/60Hz in North America). Mismatched voltage can lead to equipment damage or safety hazards.

Asistencia para la instalación

Clarify the level of installation support provided by the Chinese manufacturer. Many suppliers offer remote guidance via video calls or manuals, but for complex machinery such as veneer lathes, hot presses, or glue spreaders, on-site installation and commissioning by a technician may be necessary. Confirm whether this service is included in the purchase price or available at an additional cost. Request a detailed installation timeline and ask if the supplier can provide step-by-step documentation in English. Proactive planning for installation reduces downtime and ensures optimal machine performance from day one.

Términos de la garantía

Review the manufacturer’s warranty policy carefully. Standard warranties for Chinese plywood machinery typically range from De 12 a 24 meses, covering defects in materials and workmanship under normal operating conditions. Pay attention to what is excluded—wear-and-tear parts (e.g., blades, belts, rollers) are often not covered. Ensure the warranty is valid internationally and clarify the process for claiming support, including who bears shipping costs for replacement parts. A written warranty agreement in English should be included in the sales contract to avoid disputes.

Cuchillas de repuesto y kits de piezas

Due to shipping delays and lead times, it is highly recommended to purchase a comprehensive spare parts kit at the time of equipment ordering. This kit should include high-wear components such as cutting blades, knife holders, pressure rollers, drive belts, and common electrical fuses. Confirm that the supplier provides an official parts list with part numbers for future ordering. Establish a relationship with the supplier for ongoing parts supply and inquire about minimum order quantities and estimated delivery times. Keeping critical spares in stock minimizes production downtime and supports long-term operational efficiency.

In conclusion, sourcing plywood manufacturing equipment from China can offer significant cost advantages and access to advanced production technologies. However, ensuring product quality and compliance with international standards is crucial for long-term success. Buyers must prioritize suppliers who provide CE certification, which verifies that the machinery meets essential health, safety, and environmental protection requirements within the European Economic Area. Furthermore, it is highly recommended to arrange for pre-shipment inspections and on-site testing of the equipment before delivery. This step helps confirm that the machinery functions as specified, reduces the risk of operational delays, and ensures compatibility with your production needs. By verifying CE certification and conducting thorough testing prior to shipment, businesses can mitigate risks, enhance reliability, and make informed sourcing decisions that support efficient and safe plywood manufacturing operations.