In the fast-evolving wood processing industry, log debarkers are critical for maximizing yield and ensuring high-quality output. As demand for efficient, durable, and cost-effective machinery grows, Chinese manufacturers have emerged as key global players—combining advanced engineering with competitive production capabilities. This 2026 review highlights the top seven log debarker machine manufacturers renowned for innovation, reliability, and performance, helping sourcing professionals make informed procurement decisions in an increasingly competitive market.

Top 7 Log Debarkers Machine Manufacturers (2026 Review)

(Ranked by Technical Capability & Market Reputation)

#1 China Log Debarker Machine Manufacturers and Factory

Official Website: fandapelletmill.com

Fanda Machinery is one of the leading China log debarker machine manufacturers, providing the best quality equipment with competitive price….

#2 China Log Debarkers Manufacturers, Suppliers and Factory

Official Website: hanvymachinery.com

As one of the leading log debarkers manufacturers and suppliers in China, and equipped with a productive factory, welcome to import log debarkers made in China ……

#3 Debarker Manufacturer

Official Website: iem.ca

IEM manufacturers the best low maintenance, heavy duty, high capacity industrial debarkers. We manufacture debarkers for Sawmills, Pulp & Paper Mills, ……

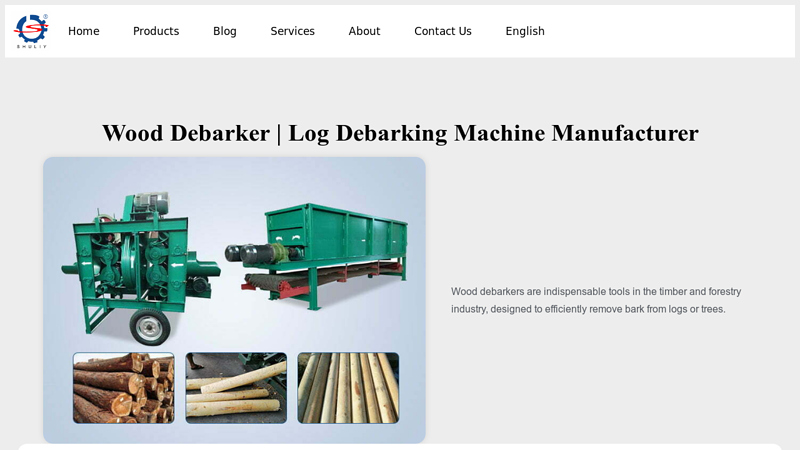

#4 Wood Debarker Log Debarking Machine Manufacturer Price

Official Website: woodmachine.org

Wood debarkers are indispensable tools in the timber and forestry industry, designed to efficiently remove bark from logs or trees….

#5 Debarkers

Official Website: valonkone.com

Our selection includes debarker models for small plants and large, high-speed production lines – in practice for all wood species used in the industry….

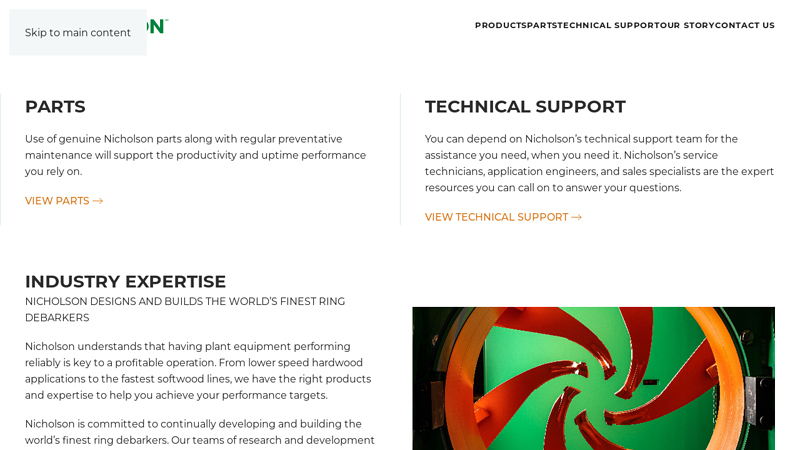

#6 Nicholson Manufacturing

Official Website: debarking.com

Nicholson ring debarkers reliably provide optimal debarking with minimal fiber loss….

#7 C

Official Website: morbark.com

The C Series Debarkers from Morbark efficiently debark logs ranging from 4 inches to 24 inches (10.2 cm to 61 cm) in diameter and up to 70 feet (21.3 m) in ……

Professional Buying Guide: Log Debarkers Machinery

2026 Global Market Trends for Log Debarkers: Focus on Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global log debarker market is poised for significant transformation by 2026, driven by technological advancements and evolving industrial demands. Key trends shaping the sector include automation, energy efficiency, high-speed production, and labor cost reduction. These factors are increasingly interwoven, as manufacturers and forestry operators seek to enhance productivity, reduce operational expenses, and meet sustainability goals. This analysis explores each of these critical areas and their expected impact on the log debarker market in 2026.

Automation in Log Debarking Systems

Automation is emerging as a dominant trend in the log debarker industry, with a growing shift toward intelligent, sensor-integrated machinery. By 2026, fully automated debarking lines are expected to become standard in medium to large-scale sawmills and biomass processing facilities. Advanced control systems, such as programmable logic controllers (PLCs) and machine vision technologies, enable real-time monitoring of log dimensions, bark thickness, and feed speed, allowing debarkers to self-adjust for optimal performance.

Robotic feeding systems and automated log turners are being integrated to minimize manual intervention. These automated features not only improve process consistency but also enhance worker safety by reducing exposure to moving machinery. Furthermore, integration with Industry 4.0 platforms allows for predictive maintenance and remote diagnostics, minimizing downtime. As a result, automation will significantly boost operational efficiency and is expected to be a key differentiator among debarker manufacturers by 2026.

Energy Efficiency and Sustainable Operation

Energy efficiency is becoming a critical performance metric in the design and operation of log debarkers. With rising energy costs and stricter environmental regulations, equipment manufacturers are focusing on reducing power consumption without sacrificing debarking effectiveness. Hydraulic and mechanical debarkers are being redesigned with variable frequency drives (VFDs), optimized rotor configurations, and low-friction components to lower energy draw.

Additionally, the shift toward electric and hybrid-powered debarking systems—particularly in European and North American markets—is accelerating. These systems align with regional carbon reduction targets and qualify for green incentives. By 2026, energy-efficient models are projected to capture over 60% of new equipment sales, especially in regions with high electricity costs or renewable energy mandates. Sustainability certifications and lifecycle energy assessments will increasingly influence procurement decisions in the forestry sector.

High-Speed Production Demands

The demand for high-speed log debarking is intensifying as sawmills and biorefineries scale up operations to meet growing global demand for wood products and biomass. Modern debarkers are being engineered for higher throughput, capable of processing 150–200 logs per hour with consistent quality. Innovations such as multi-drum configurations, improved feed mechanisms, and advanced rotor dynamics enable faster processing without compromising bark removal efficiency.

High-speed systems are particularly prevalent in integrated wood processing plants where continuous operation is essential. By 2026, manufacturers will increasingly offer modular debarking solutions that can be scaled based on production needs, allowing flexibility for both large industrial operations and mid-sized facilities. The emphasis on speed is also driving R&D into materials that reduce wear and extend maintenance intervals, ensuring sustained high performance over time.

Labor Cost Reduction and Operational Optimization

Labor cost reduction remains a primary driver behind the adoption of advanced log debarking technologies. Manual debarking and log handling are labor-intensive and increasingly difficult to staff due to workforce shortages in the forestry sector. Automated and semi-automated debarkers reduce the need for skilled operators, enabling one technician to oversee multiple machines.

By 2026, the integration of artificial intelligence (AI) and data analytics will further streamline operations, enabling autonomous decision-making for log sorting, debarking intensity, and system calibration. This reduces reliance on human oversight and minimizes errors. Additionally, remote monitoring and cloud-based management platforms will allow centralized control of multiple facilities, reducing the need for on-site personnel.

The cumulative effect of automation, energy savings, and speed improvements will lead to a significant reduction in total cost of ownership. Industry forecasts suggest that advanced debarking systems could reduce labor costs by up to 40% compared to traditional setups, making them highly attractive for cost-conscious operators.

Conclusion

By 2026, the global log debarker market will be defined by smart, energy-efficient, and high-throughput systems designed to minimize labor requirements and maximize productivity. Automation will be at the core of innovation, supported by advancements in energy efficiency and high-speed processing. As the forestry industry continues its digital and sustainable transformation, log debarker manufacturers that prioritize these four pillars will lead the market, delivering solutions that meet the economic and environmental challenges of the future.

Key Evaluation Criteria for High-Quality Log Debarkers

When selecting a high-quality log debarker, it’s essential to assess critical components that influence performance, longevity, and operational efficiency. Below are the key check points to consider:

Steel Structure Durability

The steel structure forms the backbone of the debarker and directly impacts its stability and service life. Evaluate the following:

- Material Thickness and Grade: High-quality debarkers use thick, high-tensile steel (e.g., Q345 or equivalent) to withstand heavy loads and resist deformation during continuous operation.

- Welding Quality: Look for fully automated, precision welding with stress-relieved construction to prevent cracking and ensure long-term structural integrity.

- Corrosion Protection: Powder coating or hot-dip galvanizing should be applied to protect against moisture and wood debris, especially in humid or outdoor environments.

- Frame Rigidity: A robust, reinforced frame minimizes vibration and ensures alignment of critical components like drums and rollers.

Motor Brand and Performance (e.g., Siemens, Mitsubishi)

The motor drives the debarking drum and feed system, so reliability and efficiency are crucial.

- Reputable Brands: Motors from globally recognized brands such as Siemens, Mitsubishi, ABB, or SEW are preferred due to their proven durability, energy efficiency, and consistent performance under load.

- IP Rating: Ensure motors have a high ingress protection rating (e.g., IP55 or higher) to resist dust, moisture, and wood particles.

- Variable Frequency Drives (VFD): High-end models include VFDs for adjustable drum and feed speeds, optimizing debarking results across different wood species and diameters.

PLC Control System

A sophisticated control system enhances automation, ease of operation, and troubleshooting.

- Established PLC Brands: Systems using Siemens, Mitsubishi, or Allen-Bradley PLCs offer reliable performance, faster processing, and better integration with sensors and HMIs.

- User-Friendly HMI Interface: A color touchscreen interface should allow operators to monitor machine status, adjust parameters, store settings, and receive diagnostic alerts.

- Automation Features: Look for programmable presets for different log types, automatic overload protection, and remote monitoring capabilities.

- Safety Interlocks: The PLC should manage emergency stops, door interlocks, and maintenance modes to ensure operator safety.

Spare Parts Availability

Ease of maintenance and minimal downtime depend on readily available spare parts.

- Global or Local Support: Choose manufacturers or suppliers with a strong service network and warehouse presence in your region.

- Common Components: Machines using standard bearings, seals, and drive components (e.g., from SKF, Timken, Bosch Rexroth) simplify replacements.

- Supplier Commitment: Verify the manufacturer provides long-term spare parts support—ideally 10+ years—and offers detailed parts lists with clear identification.

- Wear Parts Kit: High-quality debarkers often come with a recommended wear parts kit (e.g., hammers, liners, scraper blades) to reduce unexpected downtime.

By thoroughly evaluating these four key areas—Steel Structure Durability, Motor Brand, PLC Control System, and Spare Parts Availability—you can confidently select a high-performance, reliable log debarker that offers long-term value and minimal operational disruptions.

Guide for Importing Log Debarkers from China: Key Considerations

When importing log debarkers from China, it’s essential to address several critical factors to ensure smooth operation, safety, and long-term reliability. Below are the key aspects you should evaluate before finalizing your purchase.

Voltage Requirements (380V/220V)

Chinese-manufactured industrial machinery, including log debarkers, is often designed to operate on 380V three-phase electrical systems, which is standard in China. However, voltage requirements vary by country:

- Confirm Local Voltage Standards: Verify whether your facility uses 380V, 220V, or another voltage configuration. North America commonly uses 208V, 240V, or 480V three-phase power, while many European and Asian countries use 400V.

- Custom Voltage Options: Most reputable Chinese manufacturers can customize the motor and control systems to match your local voltage (e.g., 220V or 480V). Ensure this customization is specified in your purchase order.

- Transformer Requirements: If the machine is built for 380V and your supply is different, you may need a step-up or step-down transformer. Factor in the cost and space required for transformers in your planning.

- Electrical Compliance: Ensure the machine meets your country’s electrical safety standards (e.g., CE, UL, CSA) to avoid installation delays or safety hazards.

Installation Support

Proper installation is crucial for optimal performance and safety. Clarify the level of support the supplier offers:

- On-Site Installation Assistance: Some Chinese suppliers offer technician dispatch services for on-site installation, commissioning, and training. This may involve additional costs for travel and lodging.

- Remote Support: Many suppliers provide detailed installation manuals, videos, and real-time remote guidance via video calls or online platforms.

- Local Partnerships: Inquire if the supplier has a network of local agents or service partners in your country who can assist with setup.

- Foundation and Setup Requirements: Confirm whether the supplier provides specifications for machine foundation, anchoring, power connections, and safety clearances to prepare your facility in advance.

Warranty Terms

Understanding the warranty coverage helps protect your investment and ensures prompt resolution of issues:

- Warranty Duration: Standard warranties on Chinese log debarkers typically range from 12 to 24 months from the date of shipment or commissioning. Clarify the exact duration and what it covers.

- Coverage Scope: Review whether the warranty includes parts, labor, and shipping. Most manufacturers cover defects in materials and workmanship but exclude wear items (e.g., blades, bearings) and damage from misuse.

- Claim Process: Understand the procedure for filing warranty claims—whether parts are shipped directly, if an engineer will be dispatched, or if repairs must be done locally.

- Extended Warranty Options: Ask if extended warranty packages are available for additional peace of mind.

Spare Blade and Part Kits

Having spare parts on hand minimizes downtime and ensures continuous operation:

- Spare Blade Kits: Log debarker blades wear out with use. Purchase an initial spare blade kit (including replaceable knives, holders, and fasteners) at the time of machine purchase for immediate replacements.

- Common Wear Parts: Inquire about kits for other high-wear components such as bearings, belts, seals, and hydraulic hoses.

- Availability and Lead Times: Confirm how quickly spare parts can be supplied from China. Long shipping times can cause extended downtime, so consider stocking critical spares.

- Compatibility and Quality: Ensure that replacement parts are OEM (original equipment manufacturer) or certified compatible to maintain machine performance and safety.

- Part Number List: Request a complete spare parts list with item numbers to simplify future ordering.

By thoroughly addressing voltage compatibility, installation support, warranty details, and spare parts availability, you can confidently import a log debarker from China that meets your operational needs and delivers long-term value.

In conclusion, sourcing log debarkers from China can offer significant cost advantages and access to a wide range of machinery options. However, to ensure reliability, safety, and compliance with international standards, it is essential to verify that the equipment carries a valid CE certification. This certification confirms that the debarker meets the European Union’s health, safety, and environmental protection requirements, serving as a strong indicator of quality and compliance. Equally important is conducting thorough machine testing before shipment. Pre-shipment inspections and operational testing help confirm that the debarker performs as specified, reduce the risk of defects, and minimize potential delays or costly repairs upon arrival. By prioritizing CE certification and rigorous pre-shipment evaluation, buyers can confidently invest in high-performing, safe, and compliant log debarking equipment from Chinese suppliers.