In the fast-evolving wood processing industry, debarker machines play a pivotal role in ensuring clean, efficient log preparation. As demand for high-performance equipment grows, manufacturers are prioritizing efficiency, durability, and precision engineering. China has emerged as a global hub for advanced woodworking machinery, combining innovative design with cost-effective production. This 2026 review highlights the top seven debarker machine manufacturers renowned for robust build quality, operational reliability, and proven performance in demanding industrial environments—helping sourcing professionals make informed procurement decisions in a competitive market.

أفضل 7 شركات مصنعة لآلات تقشير الأشجار (مراجعة 2026)

(مرتبة حسب القدرة التقنية والسمعة في السوق)

#1 الصين مصنعي آلات تقشير الأخشاب ومصنعها

الموقع الرسمي: fandapelletmill.com

Fanda Machinery هي واحدة من الشركات الصينية الرائدة في تصنيع آلات تقشير الأخشاب، وتوفر معدات عالية الجودة بأسعار تنافسية....

#2 آلة تقشير جذوع الأشجار بطول 8 أقدام من الصين

الموقع الرسمي: آلة تقشير.goldsupplier.com

اكتشف منتجات آلة تقشير جذوع الأشجار بطول 8 أقدام في شركة Shandong Jinlun Machinery Manufacturing Co.، Ltd.، المصنع الصيني الموثوق. اتصل بنا لمزيد من التفاصيل!…

#3 مصنع آلة تقشير الأشجار

الموقع الرسمي: iem.ca

تقوم شركة IEM بتصنيع أفضل آلات تقشير الصناعية منخفضة الصيانة، شديدة التحمل، عالية السعة. نحن نصنع آلات تقشير للمناشر، مصانع اللب والورق، ......

#4 الصين مصنع آلة تقشير الأخشاب الموردين والمصنعين

الموقع الرسمي: logpeeling.com

YIHONG هي واحدة من أكثر الشركات احترافية في تصنيع وتوريد آلات تقشير الأخشاب في الصين. لا تتردد في شراء آلة تقشير الأخشاب المستعملة لـ......

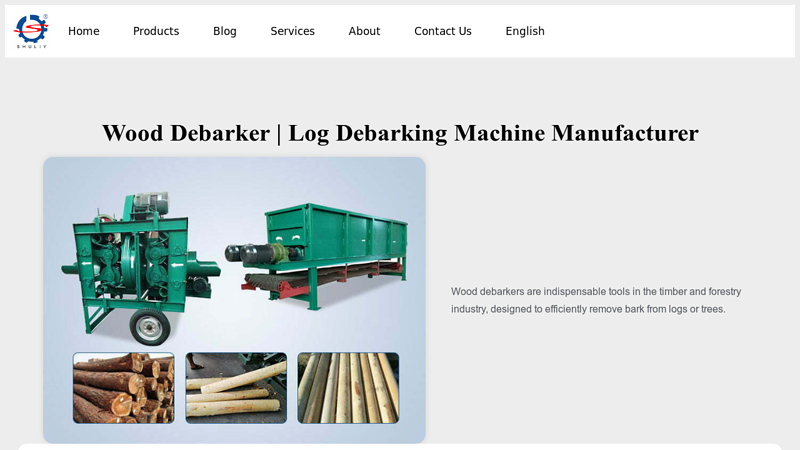

#5 آلة تقشير الخشب سعر المصنع

الموقع الرسمي: woodmachine.org

يمكن لآلة تقشير الخشب التعامل مع أنواع وأحجام مختلفة من الخشب. بفضل معدل التقشير العالي، يمكنها إزالة اللحاء بسرعة وفعالية، ......

#6 آلة تقشير لتصنيع قشرة خشب من الصين ...

الموقع الرسمي: yuequnmachinery.com

التصنيف 5.0 (46) آلة تقشير لتصنيع قشرة الخشب · 1. سهلة التشغيل وذات كفاءة إنتاجية عالية. بكرة مزدوجة وبكرة مفردة مكبرة. · 2. موثوقة ……

#7 نيكلسون للتصنيع

الموقع الرسمي: debarking.com

تلتزم شركة Nicholson بالتطوير المستمر وتصنيع أفضل آلات تقشير الأشجار في العالم. تعمل فرق مهندسي البحث والتطوير لدينا عن كثب ...

دليل الشراء الاحترافي: آلات تقشير الأشجار

2026 Global Debarker Market Trends: Automation, Energy Efficiency, High-Speed Production, and Labor Cost Reduction

The global debarker market is undergoing a significant transformation driven by increasing industrial demands, technological advancements, and economic pressures. By 2026, key trends will center around automation, energy efficiency, high-speed production, and labor cost reduction, reshaping equipment design, operational strategies, and market competitiveness.

Automation Integration Driving Operational Efficiency

By 2026, automation will be a cornerstone of advanced debarking systems. Fully automated debarkers integrated with Industry 4.0 technologies—such as IoT sensors, AI-driven analytics, and machine vision systems—will dominate high-volume operations. These systems enable real-time monitoring of bark removal efficiency, predictive maintenance, and adaptive control based on log diameter, species, and moisture content. Automated feeding and sorting lines will minimize human intervention, enhancing process consistency and reducing downtime. The integration of robotics for log handling and post-debarking inspection will further streamline operations, particularly in sawmills and biomass processing plants aiming for end-to-end digitalization.

Energy Efficiency as a Core Design and Operational Priority

With rising energy costs and stricter environmental regulations, energy efficiency will be a decisive factor in debarker selection and operation. Manufacturers will focus on developing hydraulic and mechanical systems with optimized power transmission, variable frequency drives (VFDs), and regenerative braking mechanisms to reduce electricity consumption. Innovations such as low-friction drum designs, efficient motor configurations, and smart load-sensing hydraulics will become standard. Additionally, companies will increasingly adopt renewable energy sources to power debarking operations, aligning with corporate sustainability goals and reducing carbon footprints across the wood processing value chain.

إنتاج عالي السرعة لتلبية الطلب المتزايد

Global demand for lumber, pulp, and bioenergy will continue to drive the need for high-speed debarking solutions. By 2026, debarkers capable of processing over 300 logs per hour with consistent quality will gain market share, especially in large-scale operations in North America, Northern Europe, and emerging markets in Southeast Asia. High-speed rotary and ring-type debarkers will be equipped with advanced rotor dynamics and improved knife configurations to maintain surface quality at accelerated throughput rates. The ability to handle diverse log sizes and species without frequent changeovers will further enhance production flexibility and uptime, supporting just-in-time manufacturing models.

Labor Cost Reduction Through Technological Advancements

Labor scarcity and rising wages, particularly in developed economies, will accelerate the shift toward labor-minimized debarking systems. Automated and remotely monitored debarkers will significantly reduce the need for on-site operators, lowering both direct labor costs and expenses related to training, safety, and turnover. User-friendly Human-Machine Interfaces (HMIs) and centralized control systems will allow single operators to manage multiple machines, improving labor productivity. Furthermore, reduced manual handling will enhance workplace safety, decreasing accident-related costs and insurance premiums. This trend will be especially pronounced in regions facing demographic challenges and tightening labor markets.

In conclusion, the 2026 global debarker market will be defined by intelligent, energy-conscious, and high-throughput systems designed to maximize efficiency while minimizing operational costs. Manufacturers and operators who embrace automation, energy optimization, speed, and labor reduction will gain a decisive competitive advantage in an increasingly automated and sustainable industrial landscape.

Key Check Points for Evaluating a High-Quality Debarker

When selecting a high-quality debarker for industrial applications, several critical components determine long-term performance, reliability, and operational efficiency. Below are the essential evaluation points to consider:

متانة الهيكل الفولاذي

The robustness of the debarker’s steel frame directly impacts its lifespan and resistance to heavy operational stress. Look for:

- High-Tensile Steel Construction: Frames made from reinforced, high-grade steel (e.g., Q345 or equivalent) ensure stability under continuous load.

- معالجة مضادة للتآكل: Powder-coated or hot-dip galvanized surfaces protect against moisture and rust, especially in wet or outdoor environments.

- Rigid Welded Design: A fully welded, box-type frame minimizes vibration and deformation during operation, enhancing machine longevity.

العلامة التجارية للمحرك وأدائه (على سبيل المثال، Siemens، Mitsubishi)

The motor drives the debarking mechanism and must deliver consistent, high-torque performance. Evaluate based on:

- Reputable Brand Usage: محركات من علامات تجارية معروفة عالمياً مثل سيمنز, ميتسوبيشي, ، أو ABB offer proven reliability, energy efficiency, and thermal protection.

- Power Match & Duty Rating: Ensure the motor is appropriately sized (kW/HP) for the log diameter and feed rate, with a continuous duty rating (S1) suitable for 24/7 operation.

- توافق العاكس: High-quality motors should support variable frequency drives (VFDs) for speed control and soft starts, reducing mechanical stress.

نظام التحكم PLC

An advanced PLC ensures precise control, automation, and system diagnostics. Key factors include:

- Trusted PLC Manufacturers: Systems using سيمنز, ميتسوبيشي, ، أو أومرون PLCs provide stable, programmable logic with user-friendly HMI interfaces.

- ميزات الأتمتة: Look for auto-feed control, overload protection, fault diagnostics, and adjustable debarking intensity settings.

- Remote Monitoring & Data Logging: Modern PLCs offer connectivity (e.g., Ethernet/IP, Modbus) for remote troubleshooting and performance tracking.

توافر قطع الغيار

Minimizing downtime is crucial—readily available spare parts ensure quick repairs and sustained operation.

- شبكة دعم عالمية أو محلية: Choose suppliers with established service centers and inventory in your region.

- المكونات القياسية: Machines using common, off-the-shelf parts (e.g., bearings, seals, chains) reduce replacement lead times.

- التزام المورد: Verify the manufacturer offers long-term parts supply (10+ years) and provides a detailed spare parts list with the machine.

By thoroughly assessing these four key areas—متانة الهيكل الفولاذي, ماركة المحرك, نظام التحكم PLC, ، و توافر قطع الغيار—you can confidently select a high-quality debarker that delivers reliable, efficient performance over its operational life.

دليل لاستيراد آلة تقشير من الصين: اعتبارات أساسية

متطلبات الجهد الكهربائي (380 فولت/220 فولت)

When importing a debarker from China, it’s crucial to confirm the machine’s electrical specifications match your local power supply. Most industrial machinery manufactured in China operates on 380 فولت، ثلاثي الطور، 50 هرتز, which is standard across Chinese factories. However, some smaller or customized models may be available in 220 فولت، أحادي الطور التكوينات.

- تحقق من توافق الجهد الكهربائي: Ensure your facility can support 380V 3-phase power. If your location uses 480V or 415V systems (common in North America or Europe), you may need a step-down transformer or a custom-built machine.

- Request Electrical Drawings: Ask the supplier for detailed electrical schematics and motor specifications before finalizing the order.

- خيارات الجهد المخصص: Reputable manufacturers can often customize the motor and control panel to meet your voltage needs—confirm this capability and any added cost or lead time.

دعم التثبيت

Proper installation is key to optimal debarker performance and safety. Evaluate the level of support offered by the Chinese supplier:

- On-Site Technical Assistance: Some suppliers offer technician派遣 (dispatch) services for on-site installation, commissioning, and operator training—often for an additional fee. Clarify travel costs, duration, and language support (preferably English-speaking technicians).

- التوجيه عن بعد: If on-site support isn’t feasible, ensure the supplier provides comprehensive installation manuals, video tutorials, and remote troubleshooting via phone or video call.

- متطلبات التأسيس والإعداد: Confirm if the supplier provides specifications for foundation preparation, material feed systems, and utility connections (power, air, water).

شروط الضمان

Warranty coverage varies significantly among Chinese manufacturers. Carefully review the terms before purchase:

- فترة الضمان القياسية: Most offer a ضمان لمدة 12 شهراً on main components (motor, gearbox, frame), but exclude wear items like blades, bearings, and belts.

- تفاصيل التغطية: Warranty typically covers manufacturing defects, not damage due to improper use, lack of maintenance, or incorrect installation.

- الصيانة والإصلاحات: Clarify how warranty claims are handled—whether parts are shipped free of charge, if technical support is included, and who covers shipping costs (usually split or paid by buyer).

- خيارات الضمان الممتد: Some suppliers offer extended warranties for 2–3 years—consider this for critical production equipment.

مجموعة قطع غيار الشفرات والأجزاء

Due to shipping delays and customs processing, having spare parts on hand is essential for minimizing downtime:

- مجموعات شفرات احتياطية: Request a starter kit including extra debarking blades (typically made of high-strength alloy steel), blade holders, and adjustment tools. Blades are wear items and may need replacement every few weeks to months depending on usage.

- Comprehensive Spare Parts Package: Consider ordering a full maintenance kit with commonly replaced components such as belts, bearings, seals, hydraulic hoses (if applicable), and fuses.

- توافر طويل الأمد: Confirm the supplier can provide spare parts for at least 5–7 years post-purchase. Request a detailed parts list with OEM or equivalent part numbers.

- تخطيط المخزون: Based on expected usage, calculate spare part consumption and maintain a 6–12 month supply locally.

By addressing voltage compatibility, securing reliable installation support, understanding warranty limitations, and stocking essential spare parts, you can ensure a smooth integration of your imported debarker into your operations.

In conclusion, sourcing a debarker machine from China can offer significant cost advantages and access to advanced manufacturing capabilities. However, ensuring the quality, safety, and reliability of the equipment is paramount. It is essential to verify that the machine complies with international standards by confirming the presence of a valid CE certification, which indicates adherence to European health, safety, and environmental protection requirements. Additionally, arranging for pre-shipment inspection and functional testing of the debarker machine is crucial to ensure it performs as specified and meets your operational needs. Taking these precautions minimizes risks, avoids potential delays or failures upon arrival, and supports a successful and efficient procurement process. By prioritizing certification and thorough testing, buyers can confidently invest in high-quality machinery that delivers long-term value and performance.